You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread Matt's 93 Lx - Running Issues

- Thread starter mattyv

- Start date

-

Sponsors (?)

Post #97 has more detail but, the ECU fix helped the general running of the car but I still have code 18. My plan of action now is to recheck the TFI now that the ECU is (hopefully) fixed. I already checked the resistor on the driver side firewall and it was good.

I should have some strut tower pics, i'll have to dig for them. I basically cut out whatever was rotted and welded in some plates. I was in a time crunch so I fully expect to go back in there in a few years and clean it all up again.

I should have some strut tower pics, i'll have to dig for them. I basically cut out whatever was rotted and welded in some plates. I was in a time crunch so I fully expect to go back in there in a few years and clean it all up again.

Ok i have an update everyone. I put in the IAC and did a computer reset. It pretty much solved all of my idle issues. It doesn't want to die when it comes back to idle anymore. It still has a slight stumble off idle though.

The only code left is KOER code 18. I've gone through the wiring from ECU to TFI, ECU to coil, i double checked the 22k resistor today and all good. I did check the spout connection while idling and I'm getting around 5v. It sounds like the ECU is doing it's job then. I have to check it under load somehow more I guess. I'm not sure why I still have the code 18 though.

Last thing - the car runs good but doesn't feel like it's at its full potential. Seems low on power. I'm not sure if that has to do with the new top end and I have to bump up the fuel pressure a bit? I know a dyno tune would be ideal but not in the cards right now.

Thoughts?

The only code left is KOER code 18. I've gone through the wiring from ECU to TFI, ECU to coil, i double checked the 22k resistor today and all good. I did check the spout connection while idling and I'm getting around 5v. It sounds like the ECU is doing it's job then. I have to check it under load somehow more I guess. I'm not sure why I still have the code 18 though.

Last thing - the car runs good but doesn't feel like it's at its full potential. Seems low on power. I'm not sure if that has to do with the new top end and I have to bump up the fuel pressure a bit? I know a dyno tune would be ideal but not in the cards right now.

Thoughts?

- Jul 7, 2005

- 1,563

- 1,197

- 164

Bump the fuel pressure up to 55 psi and see if that helps. You can get a little more out of those injectors doing that and test to see if it helps your topend issue.Ok i have an update everyone. I put in the IAC and did a computer reset. It pretty much solved all of my idle issues. It doesn't want to die when it comes back to idle anymore. It still has a slight stumble off idle though.

The only code left is KOER code 18. I've gone through the wiring from ECU to TFI, ECU to coil, i double checked the 22k resistor today and all good. I did check the spout connection while idling and I'm getting around 5v. It sounds like the ECU is doing it's job then. I have to check it under load somehow more I guess. I'm not sure why I still have the code 18 though.

Last thing - the car runs good but doesn't feel like it's at its full potential. Seems low on power. I'm not sure if that has to do with the new top end and I have to bump up the fuel pressure a bit? I know a dyno tune would be ideal but not in the cards right now.

Thoughts?

Here's refresher since the original seems to have gotten lost in the previous pages.

Codes 44 & 94 - AIR system inoperative - Air Injection. Check vacuum lines for leaks, & cracks. Check for a clogged air crossover tube, where one or both sides of the tube clog with carbon.

Revised 21 Sep 2012 to correct the description of the process that sets the code and include Thermactor Air System diagram.

If you have a catalytic converter H pipe, you need to fix these codes. If you don't, then don't worry about them.

Code 44 passenger side air not functioning.

Code 94 driver side air not functioning.

The TAD solenoid/TAD diverter valve directs smog pump output to either the crossover tube attached to the cylinder heads or to the catalytic converters.

The O2 sensors are placed before the catalytic converters, so they do not see the extra O2 when the smog pump's output is directed to the converters or the input just before the converter.

The 44/94 code uses the O2 sensors to detect a shift in the O2 level in the exhaust. The smog pump provides extra air to the exhaust which raises the O2 level in the exhaust when the smog pump output is directed through the crossover tube.

When there is an absence of increase in the O2 levels when the TAD solenoid/TAD diverter valve directs air through the crossover tube, it detects the lower O2 level and sets the code.

Failure mode is usually due to a clogged air crossover tube, where one or both sides of the tube clog with carbon. The air crossover tube mounts on the back of the cylinder heads and supplies air to each of the Thermactor air passages cast into the cylinder heads. When the heads do not get the proper air delivery, they set codes 44 & 94, depending on which passage is clogged. It is possible to get both 44 & 94, which would suggest that the air pump or control valves are not working correctly, or the crossover tube is full of carbon or missing.

Testing the system:

Note that the engine must be running to do the tests unless stated otherwise. For safety’s sake, do test preparation like loosening clamps, disconnecting hoses and connecting things to a vacuum source with the engine off.

Disconnect the big hose from smog pump: with the engine running you should feel air output. Reconnect the smog pump hose & apply vacuum to the first vacuum controlled valve: Its purpose is to either dump the pump's output to the atmosphere or pass it to the next valve.

The next vacuum controlled valve directs the air to either the cylinder heads when the engine is cold or to the catalytic converter when the engine is warm. Disconnect the big hoses from the back side of the vacuum controlled valve and start the engine. Apply vacuum to the valve and see if the airflow changes from one hose to the next.

The two electrical controlled vacuum valves mounted on the rear of the passenger side wheel well turn the vacuum on & off under computer control. Check to see that both valves have +12 volts on the red wire. Then ground the white/red wire and the first solenoid should open and pass vacuum. Do the same thing to the light green/black wire on the second solenoid and it should open and pass vacuum.

Remember that the computer does not source power for any actuator or relay, but provides the ground necessary to complete the circuit. That means one side of the circuit will always be hot, and the other side will go to ground or below 1 volt as the computer switches on that circuit.

The following computer tests are done with the engine not running.

The computer provides the ground to complete the circuit to power the solenoid valve that turns the

vacuum on or off. The computer is located under the passenger side kick panel. Remove the kick panel & the cover over the computer wiring connector pins. Check Pin 38 Solenoid valve #1 that provides vacuum to the first Thermactor control valve for a switch from 12-14 volts to 1 volt or less. Do the same with pin 32 solenoid valve #2 that provides vacuum to the second Thermactor control valve. Turning the ignition to Run with the computer jumpered to self-test mode will cause all the actuators to toggle on and off. If after doing this and you see no switching of the voltage on and off, you can start testing the wiring for shorts to ground and broken wiring. An Ohm check to ground with the computer connector disconnected & the solenoid valves disconnected should show open circuit between the pin 32 and ground and again on pin 38 and ground. In like manner, there should be less than 1 ohm between pin 32 and solenoid valve #2 and pin 38 & Solenoid valve #1.

The following computer tests are done with the engine running.

If after checking the resistance of the wiring & you are sure that there are no wiring faults, start looking at the solenoid valves. If you disconnect them, you can jumper power & ground to them to verify operation with the engine running. Power & ground supplied should turn on the vacuum flow, remove either one and the vacuum should stop flowing.

Typical resistance of the solenoid valves is in the range of 20-70 Ohms.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host)

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

http://www.veryuseful.com/mustang/tech/engine/images/88-91eecPinout.gif

If you have a catalytic converter H pipe, you need to fix these codes. If you don't, then don't worry about them

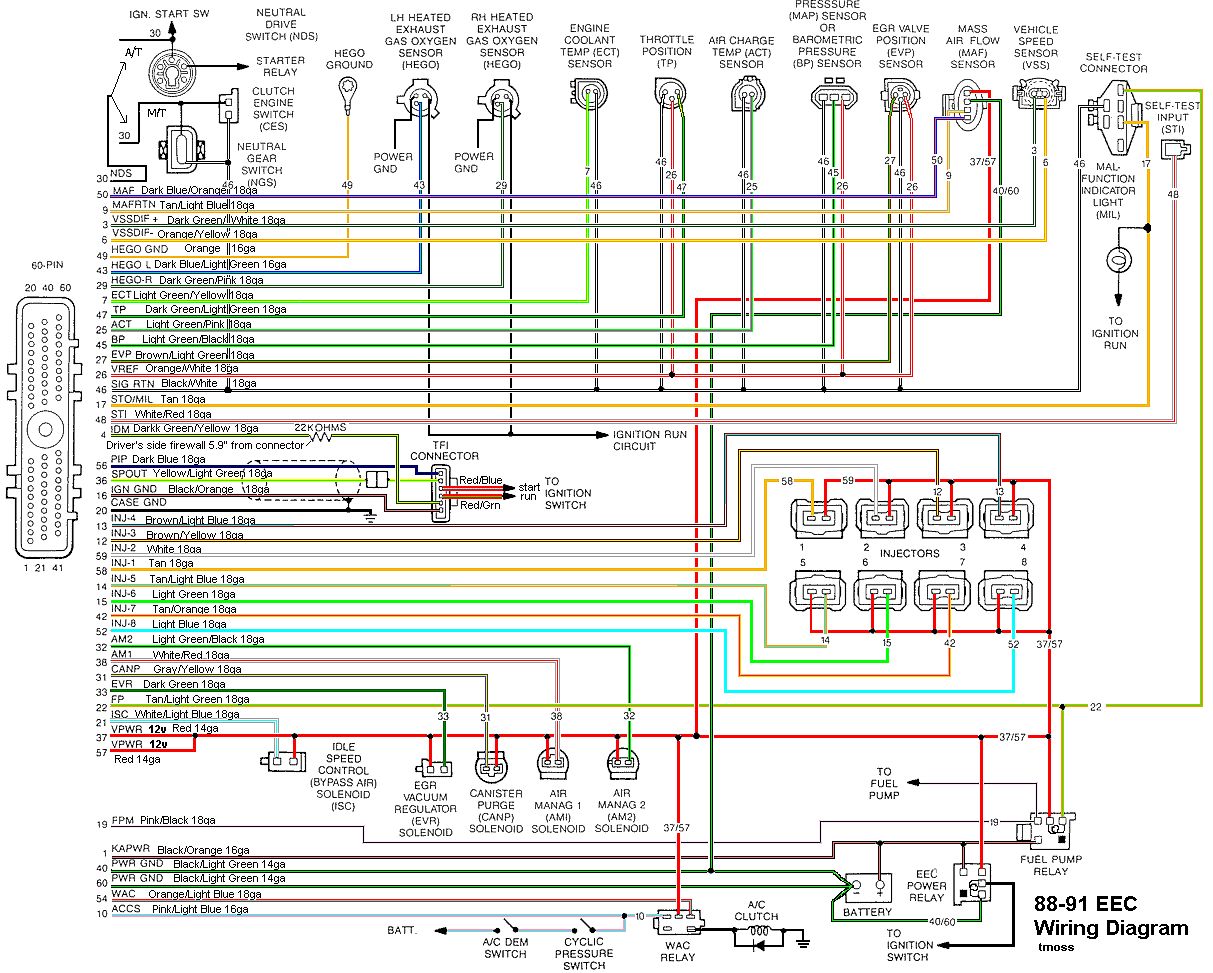

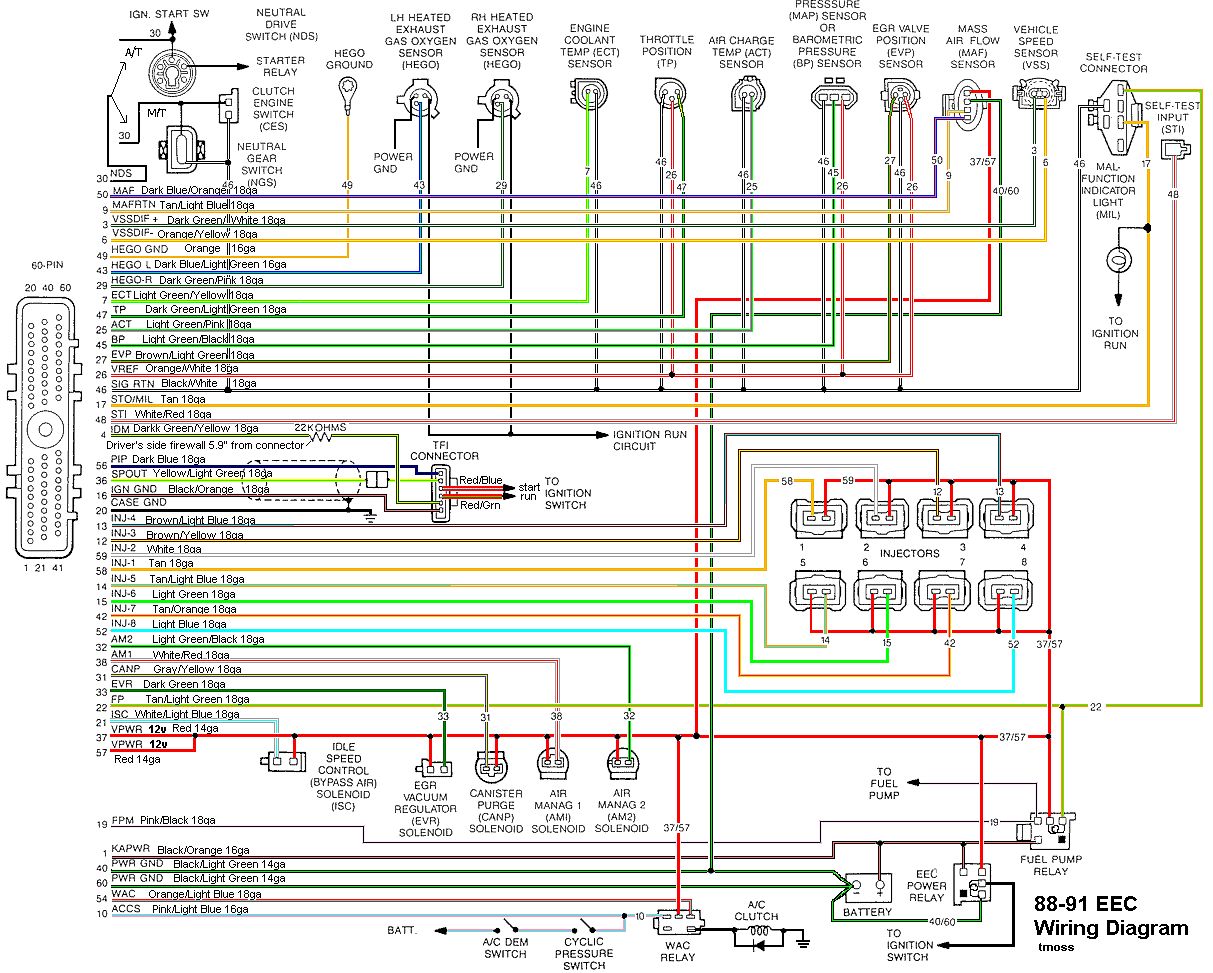

Code 18 - SPOUT out or wiring fault - look for short to ground in SPOUT wiring going

back to the computer. Possible bad TFI or defective 22 K resistor in the IDM wiring

Use a timing light to check the timing: remove the SPOUT and observe that the timing retards at least 4 degrees. Put the SPOUT back in place and observe that the spark advances at least 4 degrees.

This code can disable spark advance and reduce power and fuel economy.

Remove the passenger side kick panel and disconnect the computer connector.

There is a 10 MM bolt that holds it in place.

Disconnect the TFI module connector from the TFI and the measure the resistance between the yellow/lt green wire and ground.

You should see greater than 100 K (100000) ohms.

Check the resistance from Pin 4 on the computer connector (dark green/yellow) and the dark green/yellow wire on the TFI connector. You should see 20-24 K Ohms (20,000-24,0000 ohms).

Resistor location: A big thanks to liljoe07 for this information:

Next measure the resistance between the yellow/lt green wire on the TFI module connector and Pin 36 on the computer connector. With the SPOUT plug in place, you should see less than 2 ohms.

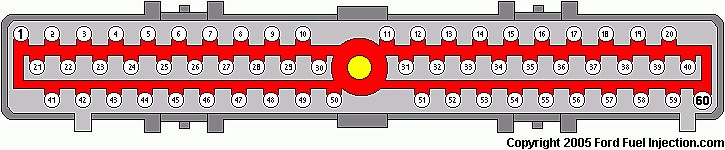

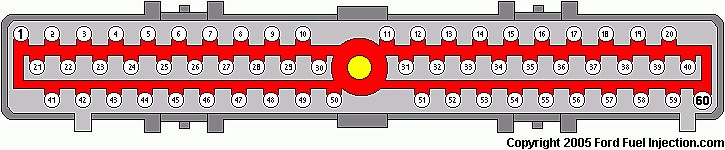

The following is a view from the computer side of the computer connector.

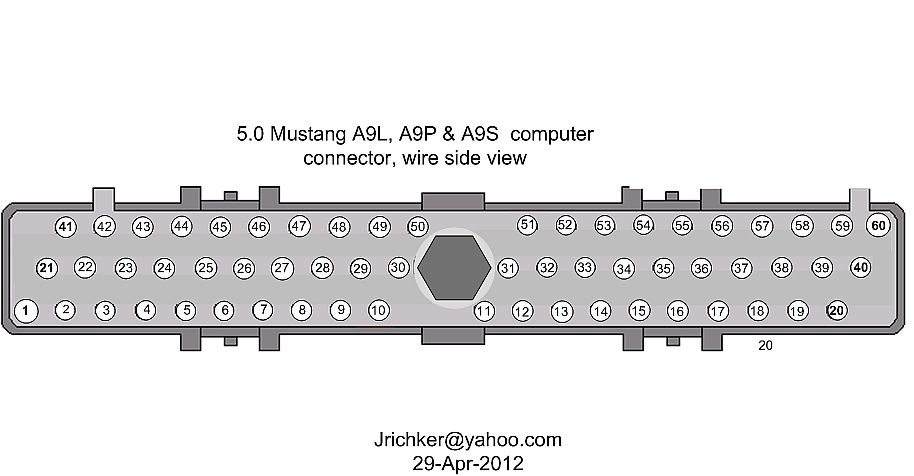

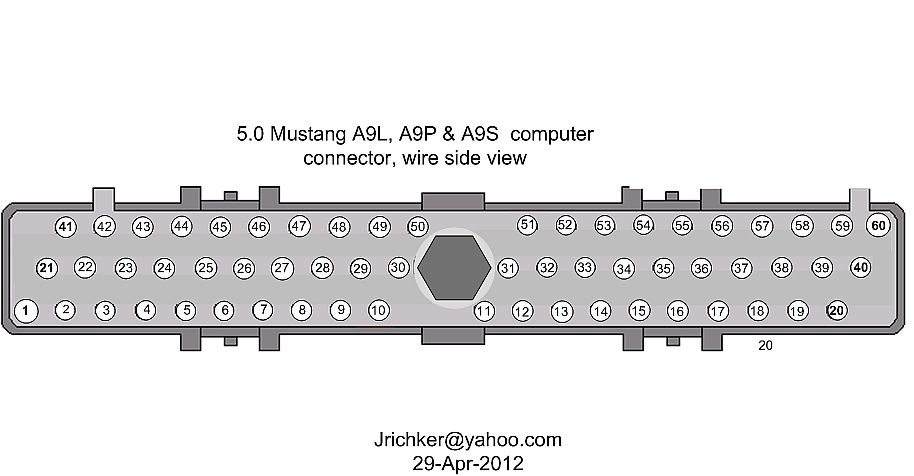

This diagram is the wire side of the computer connector.

Diagram courtesy of Tmoss & Stang&2birds

Codes 44 & 94 - AIR system inoperative - Air Injection. Check vacuum lines for leaks, & cracks. Check for a clogged air crossover tube, where one or both sides of the tube clog with carbon.

Revised 21 Sep 2012 to correct the description of the process that sets the code and include Thermactor Air System diagram.

If you have a catalytic converter H pipe, you need to fix these codes. If you don't, then don't worry about them.

Code 44 passenger side air not functioning.

Code 94 driver side air not functioning.

The TAD solenoid/TAD diverter valve directs smog pump output to either the crossover tube attached to the cylinder heads or to the catalytic converters.

The O2 sensors are placed before the catalytic converters, so they do not see the extra O2 when the smog pump's output is directed to the converters or the input just before the converter.

The 44/94 code uses the O2 sensors to detect a shift in the O2 level in the exhaust. The smog pump provides extra air to the exhaust which raises the O2 level in the exhaust when the smog pump output is directed through the crossover tube.

When there is an absence of increase in the O2 levels when the TAD solenoid/TAD diverter valve directs air through the crossover tube, it detects the lower O2 level and sets the code.

Failure mode is usually due to a clogged air crossover tube, where one or both sides of the tube clog with carbon. The air crossover tube mounts on the back of the cylinder heads and supplies air to each of the Thermactor air passages cast into the cylinder heads. When the heads do not get the proper air delivery, they set codes 44 & 94, depending on which passage is clogged. It is possible to get both 44 & 94, which would suggest that the air pump or control valves are not working correctly, or the crossover tube is full of carbon or missing.

Testing the system:

Note that the engine must be running to do the tests unless stated otherwise. For safety’s sake, do test preparation like loosening clamps, disconnecting hoses and connecting things to a vacuum source with the engine off.

Disconnect the big hose from smog pump: with the engine running you should feel air output. Reconnect the smog pump hose & apply vacuum to the first vacuum controlled valve: Its purpose is to either dump the pump's output to the atmosphere or pass it to the next valve.

The next vacuum controlled valve directs the air to either the cylinder heads when the engine is cold or to the catalytic converter when the engine is warm. Disconnect the big hoses from the back side of the vacuum controlled valve and start the engine. Apply vacuum to the valve and see if the airflow changes from one hose to the next.

The two electrical controlled vacuum valves mounted on the rear of the passenger side wheel well turn the vacuum on & off under computer control. Check to see that both valves have +12 volts on the red wire. Then ground the white/red wire and the first solenoid should open and pass vacuum. Do the same thing to the light green/black wire on the second solenoid and it should open and pass vacuum.

Remember that the computer does not source power for any actuator or relay, but provides the ground necessary to complete the circuit. That means one side of the circuit will always be hot, and the other side will go to ground or below 1 volt as the computer switches on that circuit.

The following computer tests are done with the engine not running.

The computer provides the ground to complete the circuit to power the solenoid valve that turns the

vacuum on or off. The computer is located under the passenger side kick panel. Remove the kick panel & the cover over the computer wiring connector pins. Check Pin 38 Solenoid valve #1 that provides vacuum to the first Thermactor control valve for a switch from 12-14 volts to 1 volt or less. Do the same with pin 32 solenoid valve #2 that provides vacuum to the second Thermactor control valve. Turning the ignition to Run with the computer jumpered to self-test mode will cause all the actuators to toggle on and off. If after doing this and you see no switching of the voltage on and off, you can start testing the wiring for shorts to ground and broken wiring. An Ohm check to ground with the computer connector disconnected & the solenoid valves disconnected should show open circuit between the pin 32 and ground and again on pin 38 and ground. In like manner, there should be less than 1 ohm between pin 32 and solenoid valve #2 and pin 38 & Solenoid valve #1.

The following computer tests are done with the engine running.

If after checking the resistance of the wiring & you are sure that there are no wiring faults, start looking at the solenoid valves. If you disconnect them, you can jumper power & ground to them to verify operation with the engine running. Power & ground supplied should turn on the vacuum flow, remove either one and the vacuum should stop flowing.

Typical resistance of the solenoid valves is in the range of 20-70 Ohms.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host)

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

http://www.veryuseful.com/mustang/tech/engine/images/88-91eecPinout.gif

If you have a catalytic converter H pipe, you need to fix these codes. If you don't, then don't worry about them

Code 18 - SPOUT out or wiring fault - look for short to ground in SPOUT wiring going

back to the computer. Possible bad TFI or defective 22 K resistor in the IDM wiring

Use a timing light to check the timing: remove the SPOUT and observe that the timing retards at least 4 degrees. Put the SPOUT back in place and observe that the spark advances at least 4 degrees.

This code can disable spark advance and reduce power and fuel economy.

Remove the passenger side kick panel and disconnect the computer connector.

There is a 10 MM bolt that holds it in place.

Disconnect the TFI module connector from the TFI and the measure the resistance between the yellow/lt green wire and ground.

You should see greater than 100 K (100000) ohms.

Check the resistance from Pin 4 on the computer connector (dark green/yellow) and the dark green/yellow wire on the TFI connector. You should see 20-24 K Ohms (20,000-24,0000 ohms).

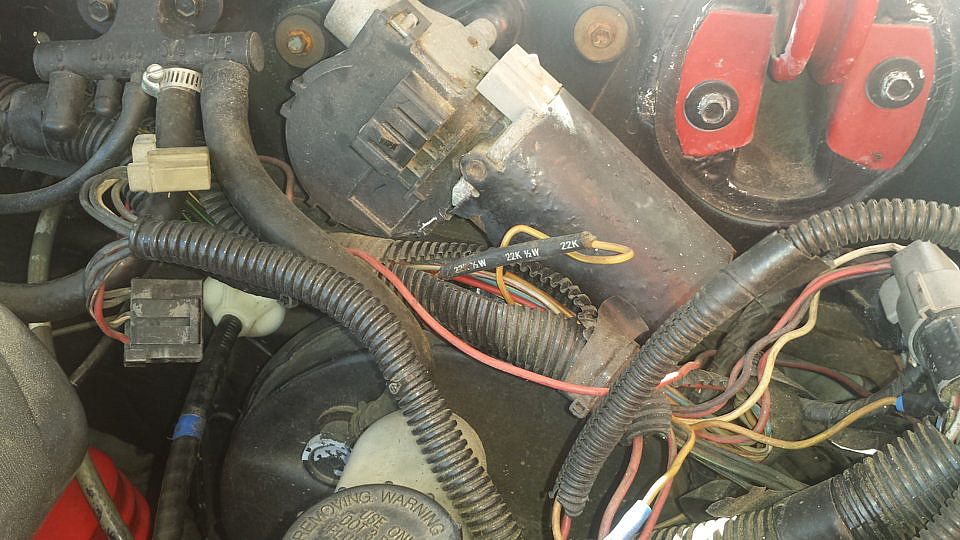

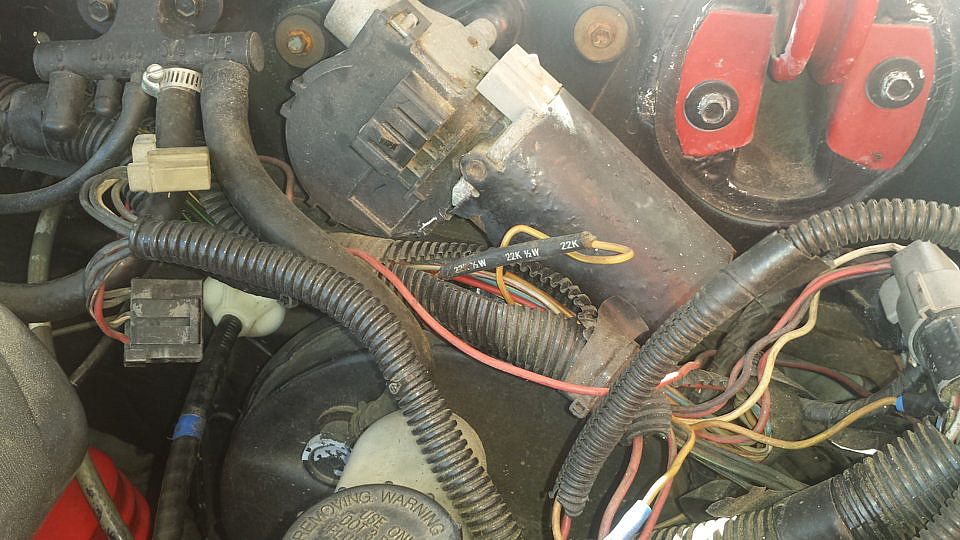

Resistor location: A big thanks to liljoe07 for this information:

Check over by the brake booster. Its not in the harness on the TFI, its on the main part of the harness over by the plugs that connect to the dash harness. About 6" or so from that, going back toward the EEC.

If I remember right, the resistor is covered in a shrink tubing that is sealed to the wires. So, you wont be able see any markings. The shrink tubing is labeled though. It's a 22kohm 1/2 watt resistor.

Here is the location.

Next measure the resistance between the yellow/lt green wire on the TFI module connector and Pin 36 on the computer connector. With the SPOUT plug in place, you should see less than 2 ohms.

The following is a view from the computer side of the computer connector.

This diagram is the wire side of the computer connector.

Diagram courtesy of Tmoss & Stang&2birds

Thank you Jrichker, extremely helpful as always. I don't have a smog pump or cats so I was ignoring the 44 and 94. I've checked the wiring to and from the Spout and they were in spec. I even have voltage from the ecu to the spout (about 5v at idle) and the 22k resistor is intact and working. I'm at a loss as to why the 18 is still coming up.

I tried bumping the fuel pressure to 55 with the vac off and it made it run MUCH better. It caused a nice surge down low but the running and driving is much better. Still feels like it's missing something though. I think I'm going to pull the trigger on a wideband meter pretty soon too. That DIYPNP MS2 is looking very very tempting right about now...

I tried bumping the fuel pressure to 55 with the vac off and it made it run MUCH better. It caused a nice surge down low but the running and driving is much better. Still feels like it's missing something though. I think I'm going to pull the trigger on a wideband meter pretty soon too. That DIYPNP MS2 is looking very very tempting right about now...

Similar threads

- Replies

- 3

- Views

- 349

- Replies

- 13

- Views

- 678

- Replies

- 13

- Views

- 1K

- Replies

- 51

- Views

- 3K