- Jul 11, 2010

- 1,135

- 64

- 69

Hey guys, just a quick question here. Do all CAI's for the 94-95 GT come with a built in plug for the intake air temp sensor? Thanks for your help...

Yes. If it doesn't have one you can drill a hole for it. I've made my own CAI and drilled a hold with teflon tape.

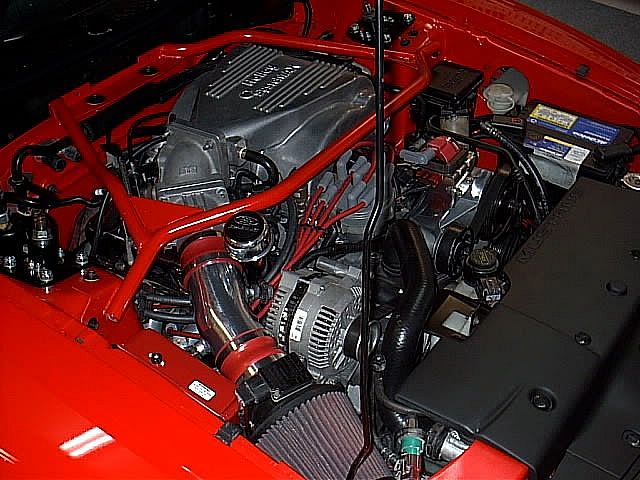

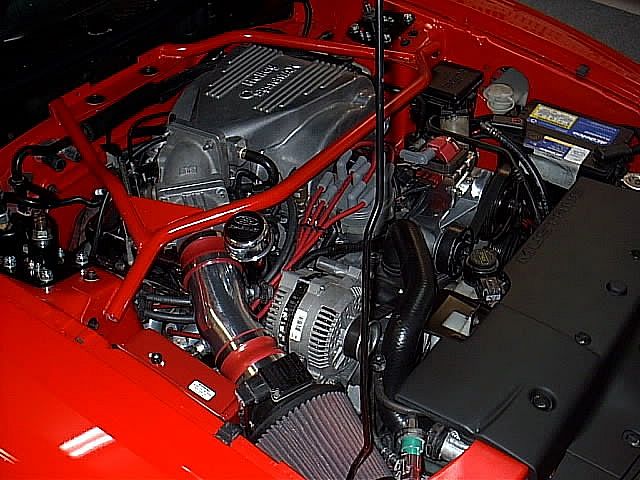

I made this one in 1997.

Cheap Ebay fender kit. I only used the pipe between the TB and MAF.

Well back in the day I spent all day on a Dyno testing several cold air kits. The ones that make the most power is a short straight shot. Those fender kits reroute air with bends and it's got a long way to go.

That would be my thought also, especially with a N/A engine. Yet I remember back when Chevy guys would say their intake manifolds were superior because the air came straight in from the front of the engine vs coming in from the side like the Mustang intake manifold. And I have even seen some of those sheet metal intake manifold manufacturers claim that the front facing intake manifold made more power than the side facing manifold on a N/A car. So I would guess that it has something to do with WOT since there is 0 vacuum at that point. The shorter and straighter the tube, the more power will be made I guess...I wonder if that would be the case with the hood closed and no external fan. As far as air flow goes, I would think that so long as the required intake flow did not exceed the flow capacity of the plumbing (air intake tube) it wouldn't matter.