Once again thank you very much for your input.

I have a set of maintenance and repair small projects to do on the rear of my foxbody. I am looking to do the least amount of damage to the car and I want to confirm or be corrected on the the rear jack points for a foxbody. We all know the rear axel is the way to go. However, I need to change the rear axel fluid since it is not leaking anymore which is letting me to believe that it is empty.

Once again, trying to avoid further damage like this post.

stangnet.com

stangnet.com

And this other post

stangnet.com

stangnet.com

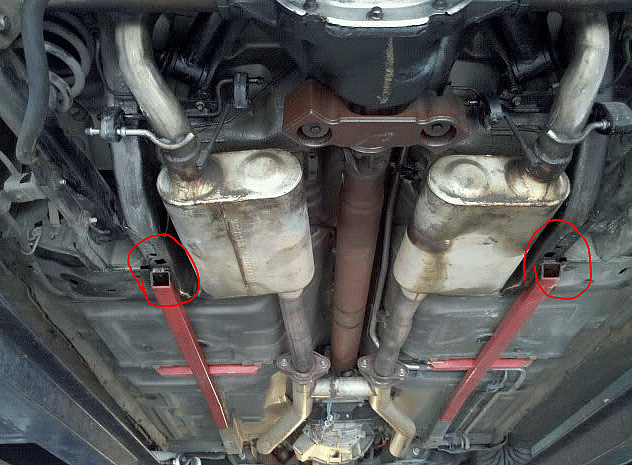

Here is my driver side with some damage already

Here is my passenger side which looks fairly OK.

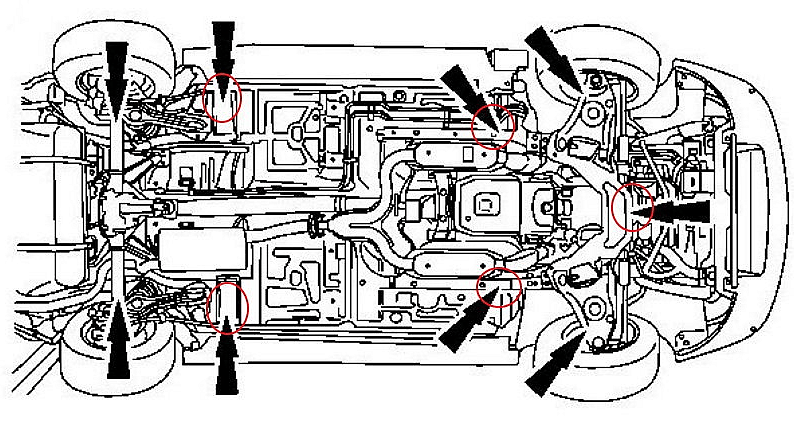

So I want to confirm the best way to place a jack stand. There is a place in front of both torque boxes.

Driver side

And passenger side

Is this a safe location to lift the rear of the car when I have to change the rear axel fluid?

Besides the rear axel fluid I also need to drop my fuel tank

stangnet.com

stangnet.com

Once again, thank you for your input.

I have a set of maintenance and repair small projects to do on the rear of my foxbody. I am looking to do the least amount of damage to the car and I want to confirm or be corrected on the the rear jack points for a foxbody. We all know the rear axel is the way to go. However, I need to change the rear axel fluid since it is not leaking anymore which is letting me to believe that it is empty.

Once again, trying to avoid further damage like this post.

Suspension - Look at these torque boxes

Looking to purchase a 93 Gt, what do you think of the torque boxes? Seller admitted he dragged with it a couple of times. Thank u!

And this other post

Paint and Body - How do my torque boxes look?

Getting ready to take the car to get the rust work done. I want to know if I need to mention the torque boxes to them to get them fixed or reinforced. I’ll attach some pics below. Drivers sides has a few small cracks on the bottom and passenger side looks pretty good to me. I don’t know much...

Here is my driver side with some damage already

Here is my passenger side which looks fairly OK.

So I want to confirm the best way to place a jack stand. There is a place in front of both torque boxes.

Driver side

And passenger side

Is this a safe location to lift the rear of the car when I have to change the rear axel fluid?

Besides the rear axel fluid I also need to drop my fuel tank

Fox - Slow filling gas tank

Hello folks; Once again thank you for your expertise with this matter. As the title says, when I go fill my gas tank I am not able to open the gas nozzle full. The nozzle shuts off automatically like it was full of gas. This happens every single time. My best guess, there is some line r hose...

Once again, thank you for your input.

Last edited: