Title pretty much says it all. The guy who built my motor said he can do it, I just want to make sure that we have all the knowledge we need and all the tips before we get it done and back into the car. Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

how hard to rebuild T-5 and any tips

- Thread starter 87GT 306

- Start date

-

Sponsors (?)

I bought the kit from hanlon motorsports for a world class T-5 and also ordered the steel bearing retainer.

jackchan

New Member

I am rebuilding my t-5 also and got the super aloy 2.95 geaat set from Astro as well as a new King Cobra clutch and bearing retainer. For some reason I cant dl your file it just says I am not loged in and of course I am!!

87GT 306 said:I bought the kit from hanlon motorsports for a world class T-5 and also ordered the steel bearing retainer.

Did the Hanlon rebuild kit not come with any instructions?

i havnt got it yet i dk.8950HO said:Did the Hanlon rebuild kit not come with any instructions?

jackchan

New Member

ok if I get in trouble for using to much band width I'm gonna skin ya head!

1.Place Transmission in Neutral

Remove 2 transmission Mount bolts

Remove 4 shifter bolts

Drive out 1st roll pin on shifter rail and slide back mechanism

Remove Neutral safety Switch & tail housing

Remove Tail housing bolts and tail housing

3.Remove Fifth gear synchronizer and shift fork by removing snap ring, and 5th gear retainer

Drive out the shift rail roll pin and remove synchronizer and fork as an assembly.

Remove fork inserts.

4.Remove 4 bearing retainer bolts and remove input shaft

Remove output shaft assembly (Remove the snap ring and fifth gear push the output shaft group to the rear to dislodge the bearing cup

(remove the snap ring and fifth driven gear later)

The assembly can now be tilted and removed from the case.

5.To remove fifth-R shift lever, remove the retaining clip followed by the pivot pin, then remove the lever. (this is where you use the pipe with the hole in it to protect shaft.)

6. Remove the reverse fork and idler gear by first removing the rear retainer and shim, unhooking the spring, then remove the fork pin and roller assembly. Next drive out the reverse idler shaft roll pin, push the reverse idler shaft through the rear of the case, then remove the roll pin, idler gear assembly, and O-ring from the case.

7. Push the countershaft bearing cup and thrust plate out of the case by pushing on the countershaft gear toward the rear.

Cut the cage on the rear bearing, as the rear bearing must be removed before the cluster will come out. The countershaft shaft can now be tilted and lifted out of the case. Drive out the forward bearing cup assembly from the case and remove the O-ring from the cup. A hydraulic press can be used to remove the front bearing from the countershaft. Another trick is to carefully use two opposing prybars to pry the front bearing off of the shaft.

8. use a press or puller (our puller has been made from angle iron and all thread welded to it) behind the third speed gear to start the parts coming off of the output shaft. You will remove the two blocker rings, third-fourth synchronizer assembly, third speed gear, bearing, and spacer. (secure shaft in vise)

9. Remove snap ring to remove the thrust washer, second speed gear, bearing and spacer.

10. Remove the next retaining ring and thrust washer to free up the inner cone, outer cone race, and one-two blocking ring

11. Index the reverse sliding gear to the output shaft in order to realign the clutch teeth to the original position upon reassembly, next remove the retaining springs and remove the reverse sliding gear from the shaft. This will free the inserts in the hub. DO NOT PRESS OFF THE HUB! This will ruin the shaft

12. flip the shaft over in the vice. And remove the speedometer gear by removing the snap ring from the shaft.

Dislodge clip and slide gear rearward removing it.

Next Remove this snap ring and using a puller, remove the bearing.

13. Remove the first speed gear and caged bearing, then either the single, double-row bearing, or the two bearings and spacer. Depending on your application.

Next Remove the bearing sleeve. To complete the teardown, dissemble the third-fourth and fifth synchronizer assembles. Index the sleeves and hubs so that the clutch teeth and faces can be reassembled as they were origionally (they are factory-matched) Remove the springs, then slide the sleeves from the hubs to free the inserts.

14.Clean tranny case, extension housing, Apply a thin coat of gasket sealer to (cluster gear)Countershaft bearing cup and reinstall, install a new O-ring in the OD grove and tap cup flush with inside of case.

15.Reassemble!!!

Start the front (clustergear) countershaft bearing onto the shaft, then seat firmly into the shaft shoulders with a tubular drift. Install the counter shaft! Then install the rear bearing. Tap the countershaft bearing cup into place, then install the shim and rear retainer.

16. Set a dial indicator to the end of the shaft and move the shaft back and forth to measure end play. (0.0018 in or 0.046mm)

The manual recommends that endplay be between 0.0005 to 0.0040 inches.

(Bob Hanlon Prefers 0.0000 to 0.0020 inches.)

This will provide a light drag that will loosen as the case moves and expands.

When proper end play is achieved (Via shims), torque the rear retainer to 15 ft lbs. Bend the locking tabs against the bolts.

17. Install the reverse idler shaft through the case, with the pin hole pointing upward. Place the reverse idler gear and O-ring in the case boss. Use a drift to center the roll pin in the shaft.

18. Reinstall the shift fork lever and shift fork and spring assembly. Engageing the fork into the reverse idler gear groove.

19. Install the white plastic oiler in the end of the countershaft (cluster gear)

20. Install 1st gear blocking ring, outer cone race, and inner cone onto the shaft.

21.Install the bearing sleeve and double row bearing (or double bearings and spacer if applicable)

Be sure to dip All bearings in tranny lubricant before installing.

22. Install 1st speed gear, bearing and Fifth driven gear onto the shaft.

23. The Fifth driven gear and appropriately sized. Spacer (the old bearing race works well) is used to press the bearing into place. Seat it until the snap ring groove clears the outside end of the fifth driven gear.

24. Install the snap ring

25. Reinstall the speedo gear. Lightly tapping the shaft while adjusting the gear will help position it.

26. Place the inserts (dogs) in the hub (a rubber band will help hold them in place) then position the reverse sliding gear onto the hub.

27. Some world class shafts require this ball and spring to be replaced in the hub. The newer ones will not.

28. Working now on the forward end of the shaft!

Install the second gear blocking ring, outer cone race, inner cone, thrust washer, and retaining ring (spiraled)

29.Next comes the double-row bearing, second speed gear, and thrust washer which are held in place with a snap ring.

30. Install the final double row bearing, Third Speed gear, and blocking ring.

31. Install the Third-Fourth synchronizer assembly and blocking ring

32. Reinstall the output shaft into the case: and tap the bearing cup into place.

33. Install the thrust race, thrust bearing, and spacer onto the output shaft.

34. press on new input shaft bearing and install new roller bearings in the large end of the shaft.

35. Mate the input shaft to the output shaft.

Install the oil seal and bearing cup into the

bearing retainer. Lightly oil the input shaft

surface. Just in front of the caged bearing, and

secure the bearing retainer to the case

DO NOT PERMANENTLY INSTALL IT AT THIS TIME!!!

36. Reasseble the fifth synchronizer in the reverse of disassembly. Install the fifth speed drive gear, blocker ring, fifth synchronizer, synchronizer retainer, snap ring, and fifth shift fork onto the reverse rail, and secure with the roll pin.

37. Install new inserts on the Three-four and One-two shift forks. Make sure the selector arm projection engages the selector plate notch on the three-four shift fork, and that the one-two and three-four synchronizers are in the neutral position, as well as the Five-R-Shift lever. Apply a bead of RTV sealant around case surface. Position cover over case and lower it being sure the shift forks engage with the synchronizer collars, before making contact. Torque to 10 ft lbs

Tail housing bolt torque 30 ft lbs

1.Place Transmission in Neutral

Remove 2 transmission Mount bolts

Remove 4 shifter bolts

Drive out 1st roll pin on shifter rail and slide back mechanism

Remove Neutral safety Switch & tail housing

Remove Tail housing bolts and tail housing

3.Remove Fifth gear synchronizer and shift fork by removing snap ring, and 5th gear retainer

Drive out the shift rail roll pin and remove synchronizer and fork as an assembly.

Remove fork inserts.

4.Remove 4 bearing retainer bolts and remove input shaft

Remove output shaft assembly (Remove the snap ring and fifth gear push the output shaft group to the rear to dislodge the bearing cup

(remove the snap ring and fifth driven gear later)

The assembly can now be tilted and removed from the case.

5.To remove fifth-R shift lever, remove the retaining clip followed by the pivot pin, then remove the lever. (this is where you use the pipe with the hole in it to protect shaft.)

6. Remove the reverse fork and idler gear by first removing the rear retainer and shim, unhooking the spring, then remove the fork pin and roller assembly. Next drive out the reverse idler shaft roll pin, push the reverse idler shaft through the rear of the case, then remove the roll pin, idler gear assembly, and O-ring from the case.

7. Push the countershaft bearing cup and thrust plate out of the case by pushing on the countershaft gear toward the rear.

Cut the cage on the rear bearing, as the rear bearing must be removed before the cluster will come out. The countershaft shaft can now be tilted and lifted out of the case. Drive out the forward bearing cup assembly from the case and remove the O-ring from the cup. A hydraulic press can be used to remove the front bearing from the countershaft. Another trick is to carefully use two opposing prybars to pry the front bearing off of the shaft.

8. use a press or puller (our puller has been made from angle iron and all thread welded to it) behind the third speed gear to start the parts coming off of the output shaft. You will remove the two blocker rings, third-fourth synchronizer assembly, third speed gear, bearing, and spacer. (secure shaft in vise)

9. Remove snap ring to remove the thrust washer, second speed gear, bearing and spacer.

10. Remove the next retaining ring and thrust washer to free up the inner cone, outer cone race, and one-two blocking ring

11. Index the reverse sliding gear to the output shaft in order to realign the clutch teeth to the original position upon reassembly, next remove the retaining springs and remove the reverse sliding gear from the shaft. This will free the inserts in the hub. DO NOT PRESS OFF THE HUB! This will ruin the shaft

12. flip the shaft over in the vice. And remove the speedometer gear by removing the snap ring from the shaft.

Dislodge clip and slide gear rearward removing it.

Next Remove this snap ring and using a puller, remove the bearing.

13. Remove the first speed gear and caged bearing, then either the single, double-row bearing, or the two bearings and spacer. Depending on your application.

Next Remove the bearing sleeve. To complete the teardown, dissemble the third-fourth and fifth synchronizer assembles. Index the sleeves and hubs so that the clutch teeth and faces can be reassembled as they were origionally (they are factory-matched) Remove the springs, then slide the sleeves from the hubs to free the inserts.

14.Clean tranny case, extension housing, Apply a thin coat of gasket sealer to (cluster gear)Countershaft bearing cup and reinstall, install a new O-ring in the OD grove and tap cup flush with inside of case.

15.Reassemble!!!

Start the front (clustergear) countershaft bearing onto the shaft, then seat firmly into the shaft shoulders with a tubular drift. Install the counter shaft! Then install the rear bearing. Tap the countershaft bearing cup into place, then install the shim and rear retainer.

16. Set a dial indicator to the end of the shaft and move the shaft back and forth to measure end play. (0.0018 in or 0.046mm)

The manual recommends that endplay be between 0.0005 to 0.0040 inches.

(Bob Hanlon Prefers 0.0000 to 0.0020 inches.)

This will provide a light drag that will loosen as the case moves and expands.

When proper end play is achieved (Via shims), torque the rear retainer to 15 ft lbs. Bend the locking tabs against the bolts.

17. Install the reverse idler shaft through the case, with the pin hole pointing upward. Place the reverse idler gear and O-ring in the case boss. Use a drift to center the roll pin in the shaft.

18. Reinstall the shift fork lever and shift fork and spring assembly. Engageing the fork into the reverse idler gear groove.

19. Install the white plastic oiler in the end of the countershaft (cluster gear)

20. Install 1st gear blocking ring, outer cone race, and inner cone onto the shaft.

21.Install the bearing sleeve and double row bearing (or double bearings and spacer if applicable)

Be sure to dip All bearings in tranny lubricant before installing.

22. Install 1st speed gear, bearing and Fifth driven gear onto the shaft.

23. The Fifth driven gear and appropriately sized. Spacer (the old bearing race works well) is used to press the bearing into place. Seat it until the snap ring groove clears the outside end of the fifth driven gear.

24. Install the snap ring

25. Reinstall the speedo gear. Lightly tapping the shaft while adjusting the gear will help position it.

26. Place the inserts (dogs) in the hub (a rubber band will help hold them in place) then position the reverse sliding gear onto the hub.

27. Some world class shafts require this ball and spring to be replaced in the hub. The newer ones will not.

28. Working now on the forward end of the shaft!

Install the second gear blocking ring, outer cone race, inner cone, thrust washer, and retaining ring (spiraled)

29.Next comes the double-row bearing, second speed gear, and thrust washer which are held in place with a snap ring.

30. Install the final double row bearing, Third Speed gear, and blocking ring.

31. Install the Third-Fourth synchronizer assembly and blocking ring

32. Reinstall the output shaft into the case: and tap the bearing cup into place.

33. Install the thrust race, thrust bearing, and spacer onto the output shaft.

34. press on new input shaft bearing and install new roller bearings in the large end of the shaft.

35. Mate the input shaft to the output shaft.

Install the oil seal and bearing cup into the

bearing retainer. Lightly oil the input shaft

surface. Just in front of the caged bearing, and

secure the bearing retainer to the case

DO NOT PERMANENTLY INSTALL IT AT THIS TIME!!!

36. Reasseble the fifth synchronizer in the reverse of disassembly. Install the fifth speed drive gear, blocker ring, fifth synchronizer, synchronizer retainer, snap ring, and fifth shift fork onto the reverse rail, and secure with the roll pin.

37. Install new inserts on the Three-four and One-two shift forks. Make sure the selector arm projection engages the selector plate notch on the three-four shift fork, and that the one-two and three-four synchronizers are in the neutral position, as well as the Five-R-Shift lever. Apply a bead of RTV sealant around case surface. Position cover over case and lower it being sure the shift forks engage with the synchronizer collars, before making contact. Torque to 10 ft lbs

Tail housing bolt torque 30 ft lbs

See http://www.ttcautomotive.com/English/onlineorder/product.asp to download a FREE service manual for T5 or Tremec 3550

You will need the Adobe Acrobat viewer which is also a free download – http://www.adobe.com/products/acrobat/readstep2.html

See http://www.hanlonmotorsports.com/ or http://www.ddperformance.com for parts

A T5 rebuild kit with syncros, bearings and other small parts costs about $160. It does not include any gears or shafts.

http://cartapes.com also has a video on how to rebuild your T5 or Tremec. It costs less than $20, and is worth every penny of it.

I did a Tremec 3550 rebuild, and it wasn't that difficult. The video was an immense help, and I would recommend viewing it. At $20, it will give you an opportunity to look and decide for yourself if you think that it is something you want to try to do.

You will need the Adobe Acrobat viewer which is also a free download – http://www.adobe.com/products/acrobat/readstep2.html

See http://www.hanlonmotorsports.com/ or http://www.ddperformance.com for parts

A T5 rebuild kit with syncros, bearings and other small parts costs about $160. It does not include any gears or shafts.

http://cartapes.com also has a video on how to rebuild your T5 or Tremec. It costs less than $20, and is worth every penny of it.

I did a Tremec 3550 rebuild, and it wasn't that difficult. The video was an immense help, and I would recommend viewing it. At $20, it will give you an opportunity to look and decide for yourself if you think that it is something you want to try to do.

Got a quote from a local shop today for a rebuild - 500$ ! and thats with me dropping it off, along with the hanlon rebuild kit. Seems awfully high to me.

jackchan

New Member

back when our shop use to build em we charged $150 labor for the rebuild on the bench. plus parts

we also charged $150-$200 for removal and reinstall plus+ parts (pilot bearing, turn flywheel etc etc...

any "good" local powertrain business will sell T-5 and T-45 rebuild parts. I know mobile, and pensacola here locally have one called "clutch and powertrain" formally know as "clutch products". This particular shop builds T-5's, re-pad clutchs, balences driveshafts etc....they also do industrial and commercial vechicles.

i.e. hardned input shaft, 2nd, 3rd, 5th gears, complete rebuild kits, input shafts, shims, etc... and they are more reasonable price wise this way.

we also charged $150-$200 for removal and reinstall plus+ parts (pilot bearing, turn flywheel etc etc...

any "good" local powertrain business will sell T-5 and T-45 rebuild parts. I know mobile, and pensacola here locally have one called "clutch and powertrain" formally know as "clutch products". This particular shop builds T-5's, re-pad clutchs, balences driveshafts etc....they also do industrial and commercial vechicles.

i.e. hardned input shaft, 2nd, 3rd, 5th gears, complete rebuild kits, input shafts, shims, etc... and they are more reasonable price wise this way.

'dkins419 said:do it yourself trust me its not hard at all. WHen i did it the only thing i needed was access to a press.

So ill need access to a press?

jackchan

New Member

it can be done without a press but you have to be careful, it would be easier with a press but sometimes the gears seperate easier than others.

good luck

about to do a rebuild myself for the first time in 5 or 6 years! (finally scared my luck is running out on my 4 banger power shifts lol)

Jack

good luck

about to do a rebuild myself for the first time in 5 or 6 years! (finally scared my luck is running out on my 4 banger power shifts lol)

Jack

I've done a couple easily with simple hand tools

I didn't use a press, but i did need a 3-jaw puller

I didn't use a press, but i did need a 3-jaw puller

the kit came in today. I didnt realize that the rebuild kits dont come w/new gears but someone said re-using the gears is ok?

jackchan

New Member

rule of thumb...........if they are sharp on the edges they need replacing in most cases!

good luck

Jack

good luck

Jack

For the most part you can reuse your gears and synchro "hard parts"

The only time you need to replace them is if they asre damaged or the dog teeth on the gear are rounded over.

IUf you had a gear that would grind, it would be a good idea to inspect that gear well

Here's a 2nd gear with damage on the dog teeth

View attachment 501266

The trans would grind badly into 2nd gear with this gear. If you see damage like this, you need to replace it.

Here's the matching 1-2 slider ont eh 2nd gear side. Most likely if the dog teeth of a gear is damaged, so is the synchro slider. You would need to replace this as well

View attachment 501268

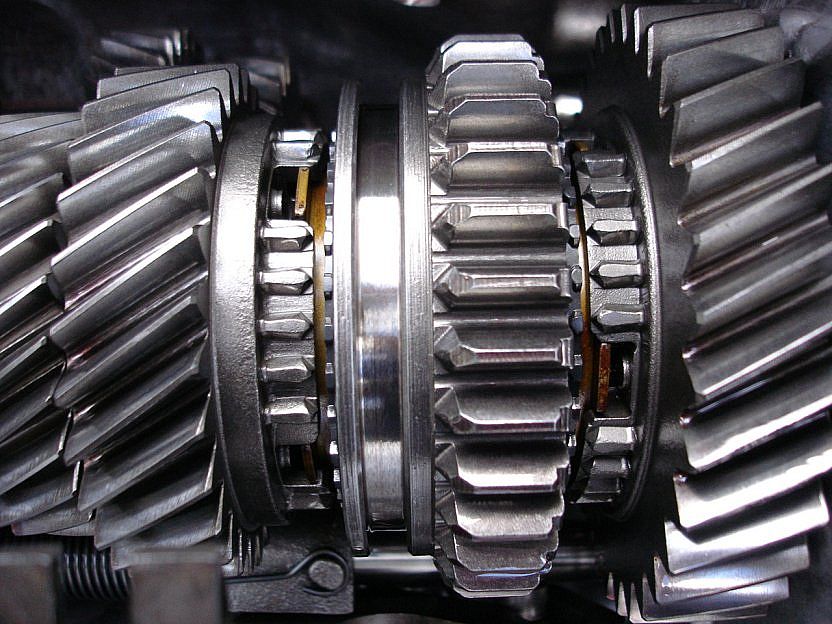

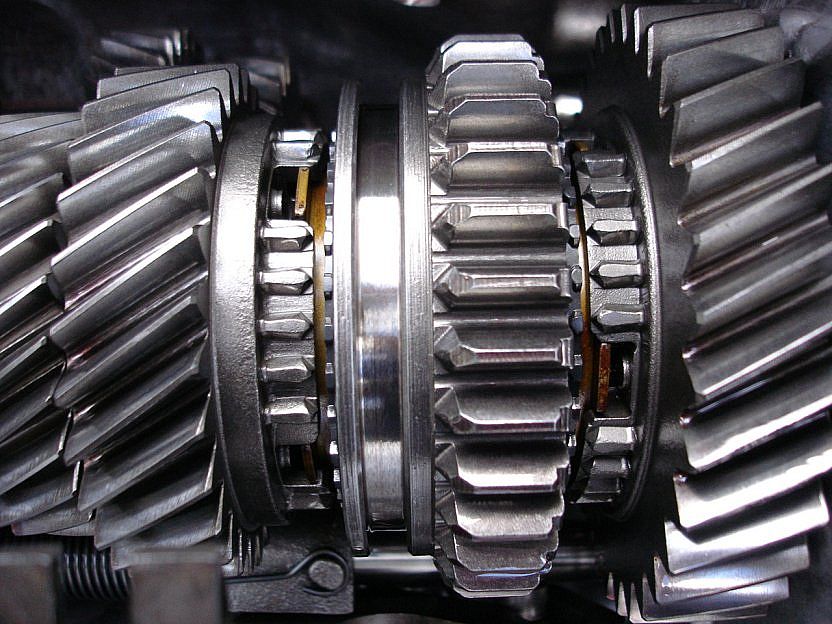

Here's a T-5 i have with 30,000 original miles. This is how the dog teeth and internal parts should look

That's the 1-2 slider dead center with 2nd gear to the left and 1st to the right

The only time you need to replace them is if they asre damaged or the dog teeth on the gear are rounded over.

IUf you had a gear that would grind, it would be a good idea to inspect that gear well

Here's a 2nd gear with damage on the dog teeth

View attachment 501266

The trans would grind badly into 2nd gear with this gear. If you see damage like this, you need to replace it.

Here's the matching 1-2 slider ont eh 2nd gear side. Most likely if the dog teeth of a gear is damaged, so is the synchro slider. You would need to replace this as well

View attachment 501268

Here's a T-5 i have with 30,000 original miles. This is how the dog teeth and internal parts should look

That's the 1-2 slider dead center with 2nd gear to the left and 1st to the right

Attachments

jackchan

New Member

Similar threads

- Replies

- 28

- Views

- 2K

- Replies

- 1

- Views

- 382

- Replies

- 3

- Views

- 361

- Replies

- 67

- Views

- 4K