so, wow, havent updated this since september huh? well, im expecting a couple summit boxes tomorrow, so let's catch up shall we?

first of all, life changes. i started a new job at the beginning of october. same base rate, but ill be staying on day shift instead of having two days notice that im moving to weekends/nights every couple of months "temporarily" (was never temporary). also 8+ hours OT every week, and no more union bs. because of all this, i've had not nearly as much car time (still enough to get some projects done), and have been pocketing some decent coin.

so what have i been working on? well, the state of the garage was getting a little frustrating. too much clutter, too much equipment taking up space, too many tools/supplies out in the air getting covered in sanding dust, and ugly yellow drywall. so, i went fixing it.

this big old shelf thing was the biggest culprit of the clutter. just became a catch-all for everything, so it had to go.

of course, all that

has to go somewhere, so i built a shed under my deck

busted up the "contraption"

painted, patched some holes,moved some cabinets around and added some more, a couple gladiator lockers that were on sale, and this is how it sits now

ill be building a new bench soon, and need to re-do the air lines, but at least the walls arent yellow and theres not a huge pile of junk anymore.

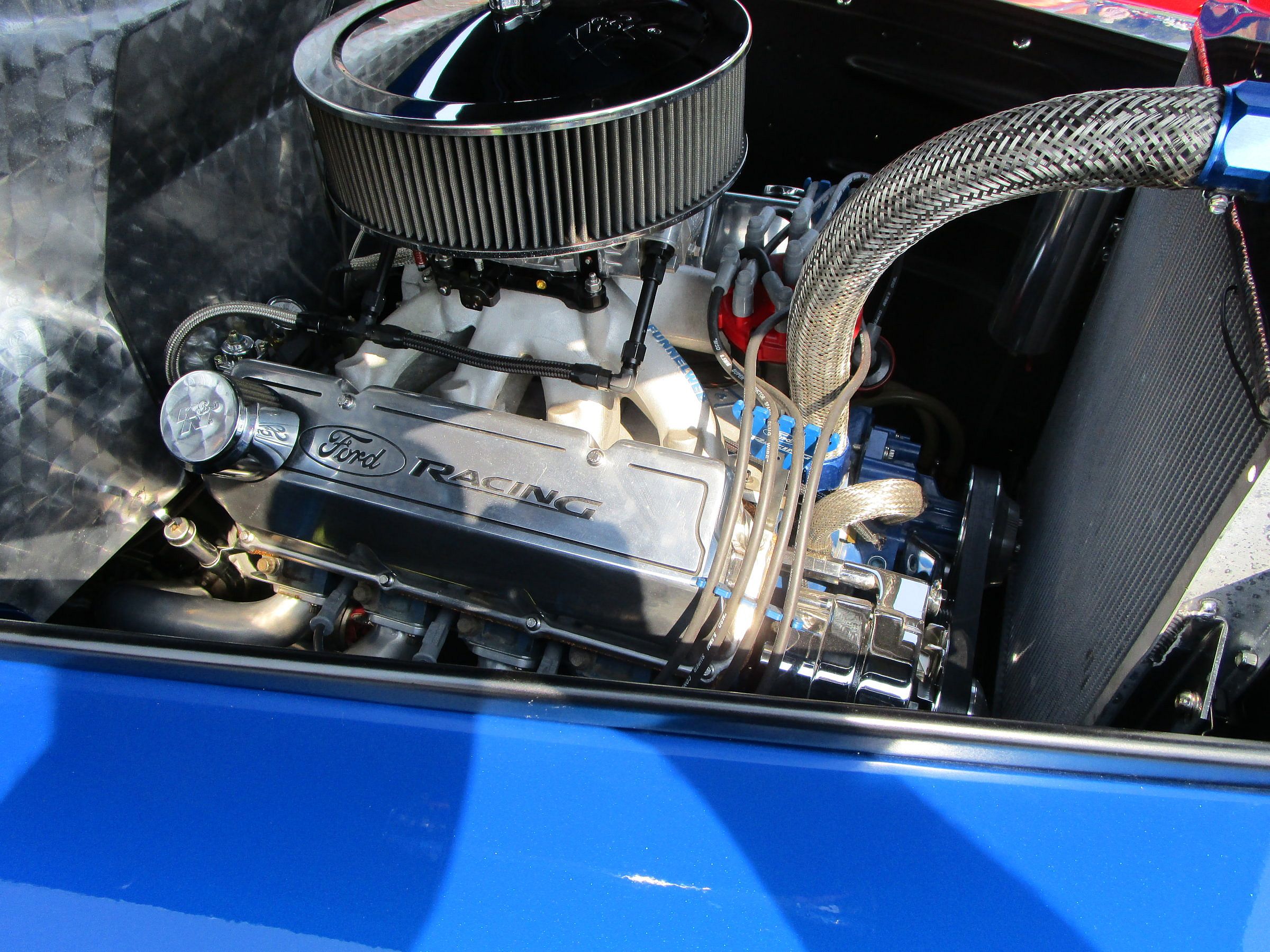

as for the fox: i got the shell stripped, epoxied, bodyworked, and a few coats of high-build on it a week or so before starting the new job, and in preparation for my summit order, got the motor pulled out in about an hour and a half this afternoon.

plan for the holiday weekend is to basically button up the motor, maybe paint it, hopefully without freezing my ass off (high in the 20's on tap the whole weekend

) .

oop:

oop:

may have to get a new job soon) finally managed to get the shell stripped (debacle), cleaned (cake), and primed (big debacle). Didn't really come out the way I wanted it to, but I think I can just block it and be ok.

may have to get a new job soon) finally managed to get the shell stripped (debacle), cleaned (cake), and primed (big debacle). Didn't really come out the way I wanted it to, but I think I can just block it and be ok.

Summit as usual was super cool about and is getting a bracket kit shipped from Edelbrock, but of course it's come from commifornia and will take over a week to get here.

Summit as usual was super cool about and is getting a bracket kit shipped from Edelbrock, but of course it's come from commifornia and will take over a week to get here.

over this '70 torino

over this '70 torino

has to go somewhere, so i built a shed under my deck

has to go somewhere, so i built a shed under my deck![IMAG0212[1].jpg IMAG0212[1].jpg](/cdn-cgi/image/format=auto,quality=80,sharpen=1/https://stangnet.com/mustang-forums/attachments/imag0212-1-jpg.595910/)

![1111171210[1].jpg 1111171210[1].jpg](/cdn-cgi/image/format=auto,quality=80,sharpen=1/https://stangnet.com/mustang-forums/attachments/1111171210-1-jpg.595911/)

![1219171840_HDR[1].jpg 1219171840_HDR[1].jpg](/cdn-cgi/image/format=auto,quality=80,sharpen=1/https://stangnet.com/mustang-forums/attachments/1219171840_hdr-1-jpg.595913/)

![1219171840[1].jpg 1219171840[1].jpg](/cdn-cgi/image/format=auto,quality=80,sharpen=1/https://stangnet.com/mustang-forums/attachments/1219171840-1-jpg.595914/)

![1219171841[1].jpg 1219171841[1].jpg](/cdn-cgi/image/format=auto,quality=80,sharpen=1/https://stangnet.com/mustang-forums/attachments/1219171841-1-jpg.595915/)

) .

) .