You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread Street/strip 427w In A Gt Hatch- Slow Progress

- Thread starter Chuckman

- Start date

-

Sponsors (?)

Gear grabber

Well-Known Member

- May 23, 2016

- 283

- 153

- 63

All motor. Would have went autolites but apparently they've gone to  the last few years.

the last few years.

Though I may add a 50-100hp cheater hit eventually for some grudge racing later on. Just a little something in case I need to pull a miracle off. Motor is NOT built for it though.

the last few years.

the last few years.Though I may add a 50-100hp cheater hit eventually for some grudge racing later on. Just a little something in case I need to pull a miracle off. Motor is NOT built for it though.

All motor. Would have went autolites but apparently they've gone tothe last few years.

Though I may add a 50-100hp cheater hit eventually for some grudge racing later on. Just a little something in case I need to pull a miracle off. Motor is NOT built for it though.

so the plan for this holiday weekend was to at least finish up the motor enough to measure up pushrod length and get it sealed up. well, long story short, that ain't going to happen until after the new year now

now, long story long, with pics!

i had woody paint the block black when he built this thing, and the more and more i looked at it, the less and less i liked that decision, so i decided to change it.

of course, that was AFTER changing the oil pan and timing cover gaskets that were siliconed in

and here's where things just got wacky

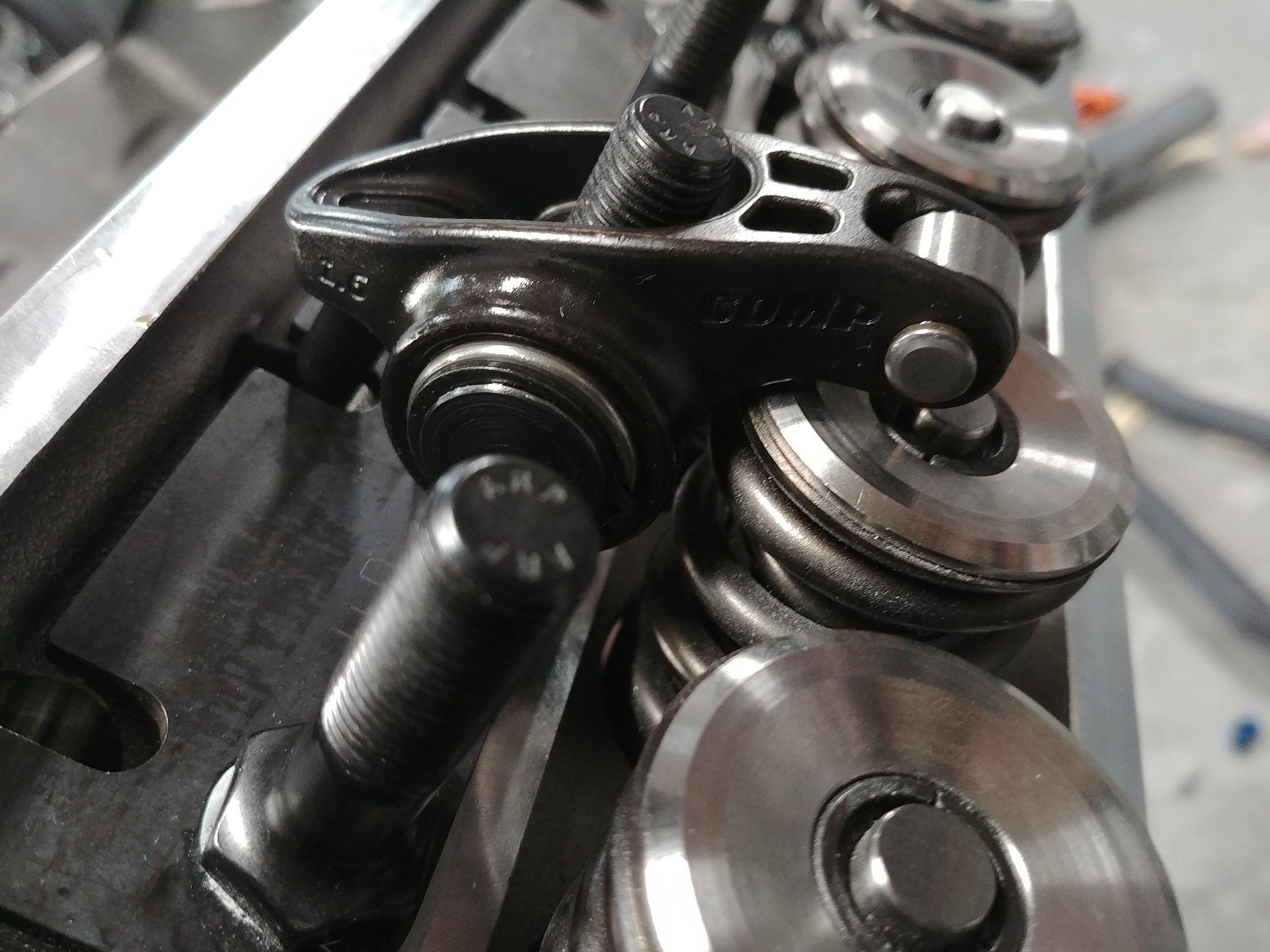

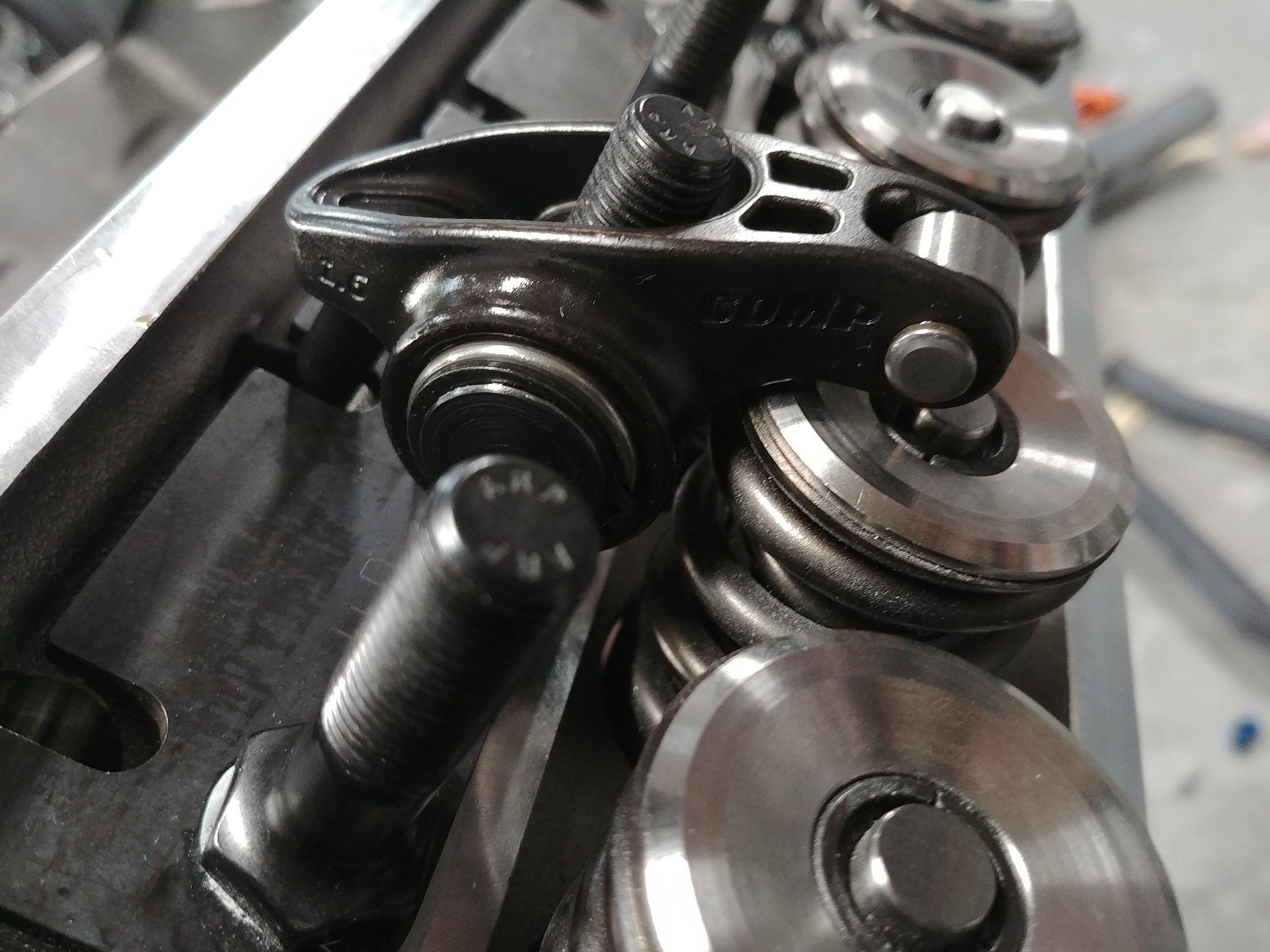

earlier in the thread, you'll see that i originally had bought arp BOLTS for these heads, and found out the hard way that the bolt heads wouldn't fit past the valve springs. so i ordered studs, and of course since im tooled for hex and despise 12-point fasteners, can you guess what which set i ordered? yup, the hex set that, while the nuts will go on the studs, also means that the needed 3/4" socket wont fit around the spring either

so i got to about it, and remembered i had some cheap chinese sockets just laying around and decided to see if i could ghetto rig a (short term) solution. heres what i came up with.

about it, and remembered i had some cheap chinese sockets just laying around and decided to see if i could ghetto rig a (short term) solution. heres what i came up with.

yup, thats a corded drill in a bench vise and an angle grinder. you can see where this is going right?

got the corners down to around .020-.030" thick. ended up working fine at 25 and 50 ft-lb, but first fastener at 75.....

so ill have to rig up another once i get some 12-pt nuts ordered

so after that fiasco, i thought to myself," well the head is at leas attached now, so i guess ill check pushrod length and try to order everything at once. what could go wrong?" shouldn't have asked that.

yup, my old tfs mock-up tool is waaaaay to short so now i get to either find some all-thread the right size tuesday, or order a new tool.

so now i get to either find some all-thread the right size tuesday, or order a new tool.

so anyway, heres how it sits now, just to show it off some since that apparently is all i can do right now

now, long story long, with pics!

i had woody paint the block black when he built this thing, and the more and more i looked at it, the less and less i liked that decision, so i decided to change it.

of course, that was AFTER changing the oil pan and timing cover gaskets that were siliconed in

and here's where things just got wacky

earlier in the thread, you'll see that i originally had bought arp BOLTS for these heads, and found out the hard way that the bolt heads wouldn't fit past the valve springs. so i ordered studs, and of course since im tooled for hex and despise 12-point fasteners, can you guess what which set i ordered? yup, the hex set that, while the nuts will go on the studs, also means that the needed 3/4" socket wont fit around the spring either

so i got to

yup, thats a corded drill in a bench vise and an angle grinder. you can see where this is going right?

got the corners down to around .020-.030" thick. ended up working fine at 25 and 50 ft-lb, but first fastener at 75.....

so ill have to rig up another once i get some 12-pt nuts ordered

so after that fiasco, i thought to myself," well the head is at leas attached now, so i guess ill check pushrod length and try to order everything at once. what could go wrong?" shouldn't have asked that.

yup, my old tfs mock-up tool is waaaaay to short

so now i get to either find some all-thread the right size tuesday, or order a new tool.

so now i get to either find some all-thread the right size tuesday, or order a new tool.so anyway, heres how it sits now, just to show it off some since that apparently is all i can do right now

Only factory part on this thing is the timing pointer lol.

Intake is just sitting in there, letting some solder on my new air system cool so I can start porting/polishing the intake. Nothing major I think, surprisingly the head/gasket/intake transition is really close. I was expecting to have to mill the f'er but it all lines up, guessing TEA did their homework or edelbrock made a rev change (or the efi 351 version doesn't have the same issues as the 8.2 version). Maybe if he's still on the board @tmoss can give some quick pointers on what NOT to do.

1262r gasket on the heads, matches up nice imo

everything looks good so far, floor lines up, but.....

more hogging required than i initially suspected

oh well, port floors still line up as do the inner walls of the inner runners (ish)

oh well, port floors still line up as do the inner walls of the inner runners (ish)

after round 1 with a cheap harbor freight cutter, newbie marks included

. im totally guessing on this btw, just trying not to bellmouth the port exits and straighten up the inside of curves.

. im totally guessing on this btw, just trying not to bellmouth the port exits and straighten up the inside of curves. looking at pics of ported stuff now to see if i want to do, and what kind of surgery on the plenum. i for sure still need to go in with some cartridge rolls and rid the thing of all the casting lumps, will probably finish in 120 grit. any pointers from anyone who has done these before would be welcome.

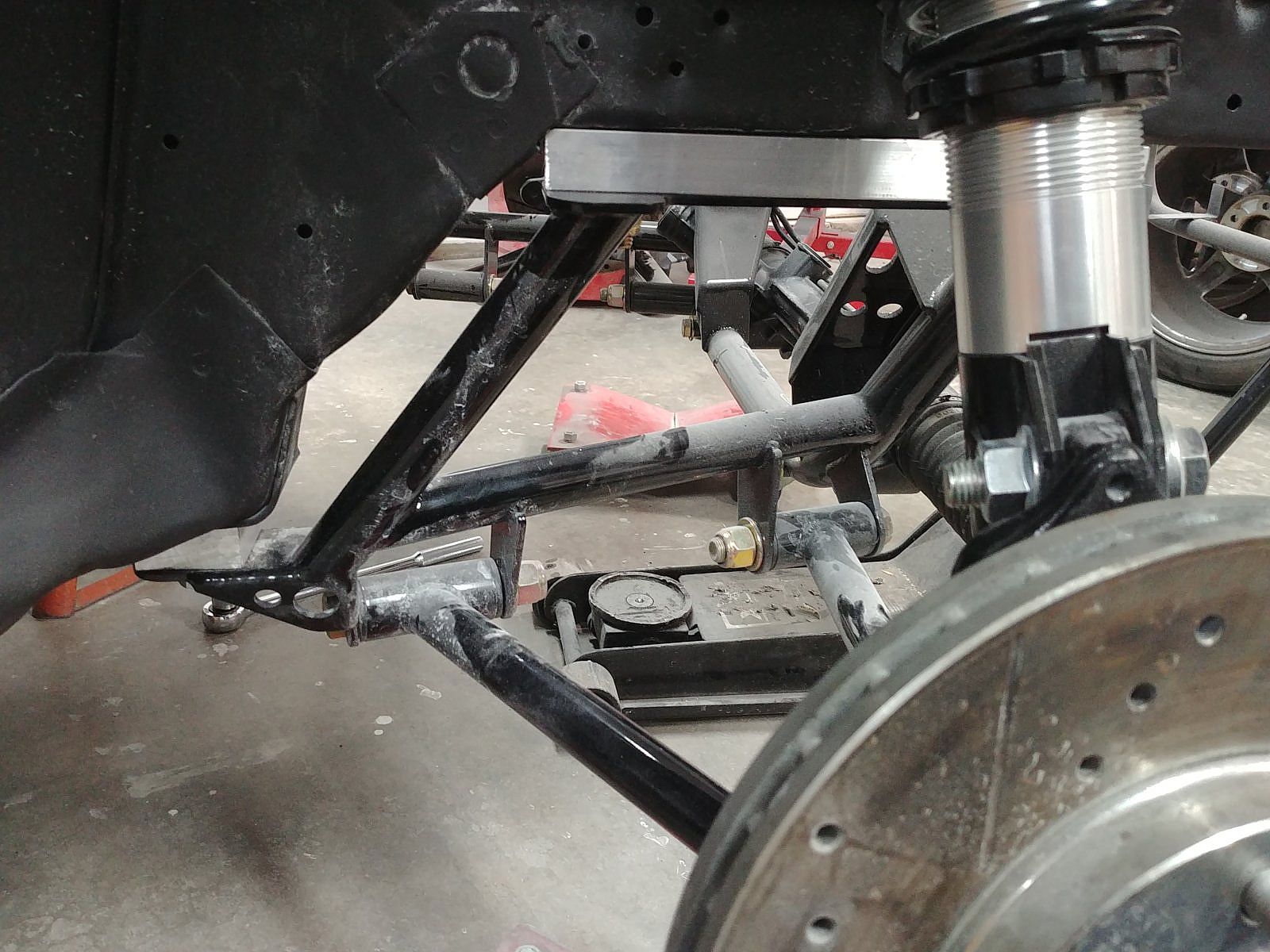

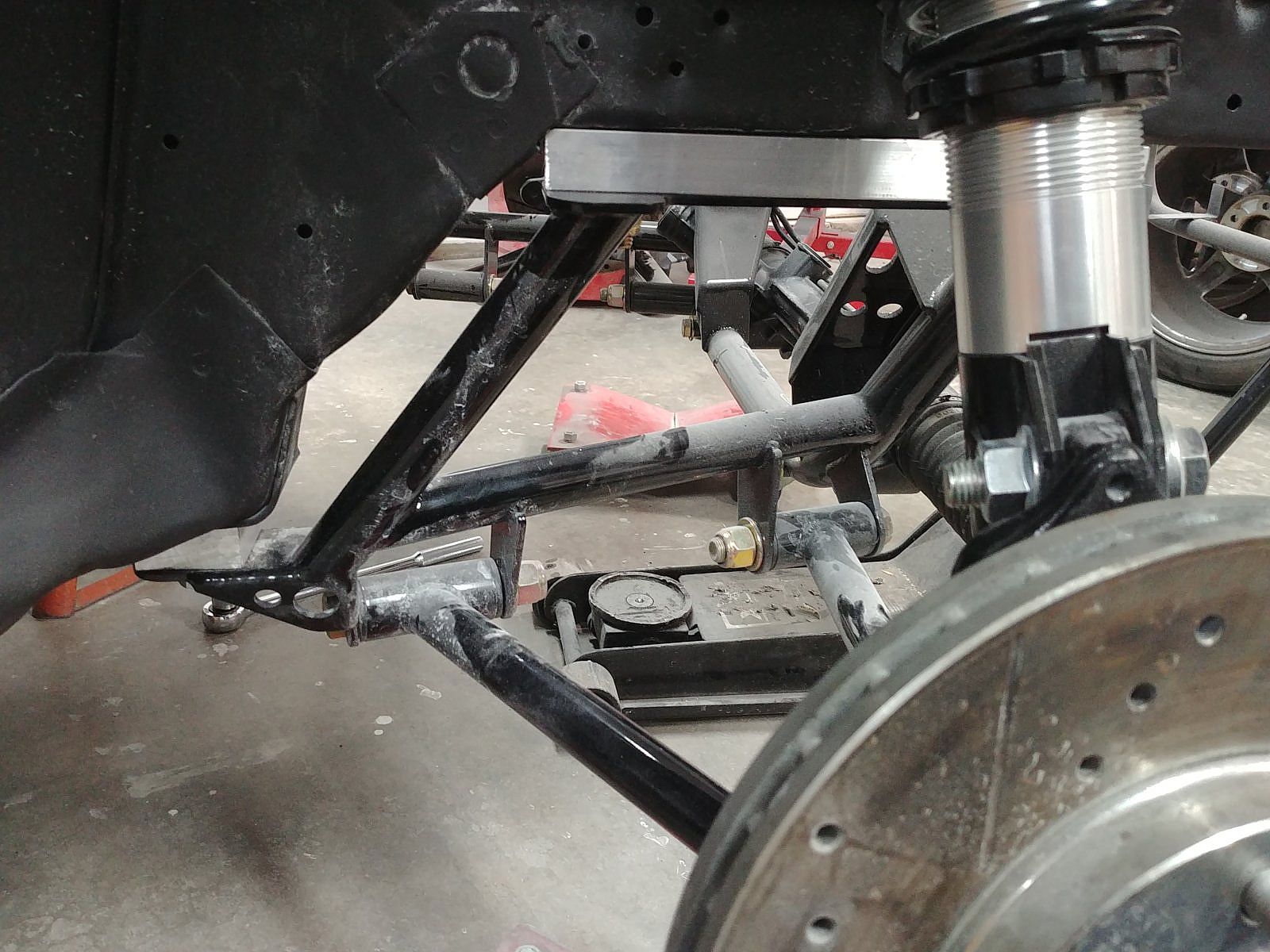

slowly but surely making more progress, ive kinda switched gears a tad and am hoping to have the thing at least running and driving by the end of the summer if the budget will allow, and do the remaining body/paint work later. just want to drive the thing, ya know?

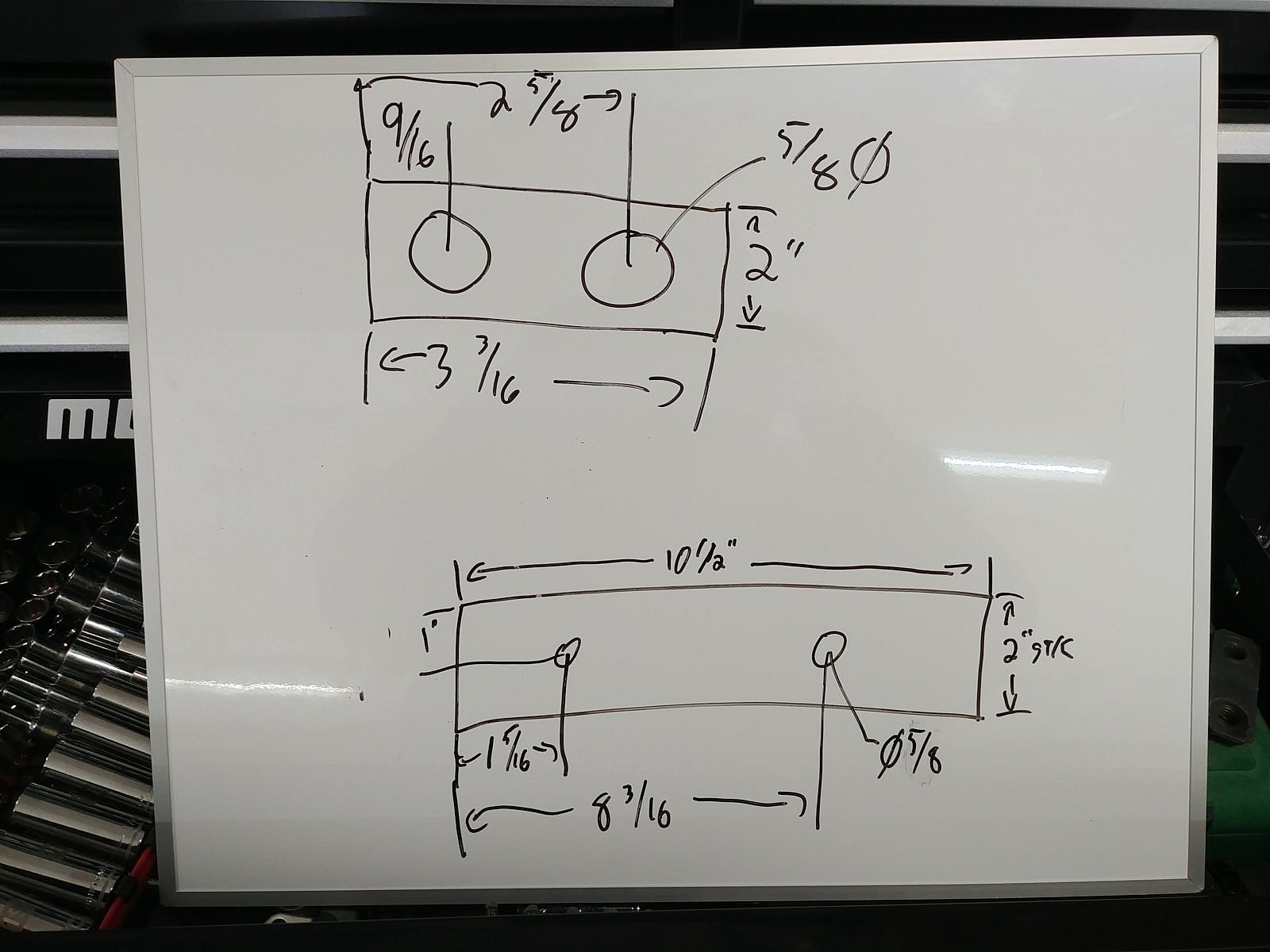

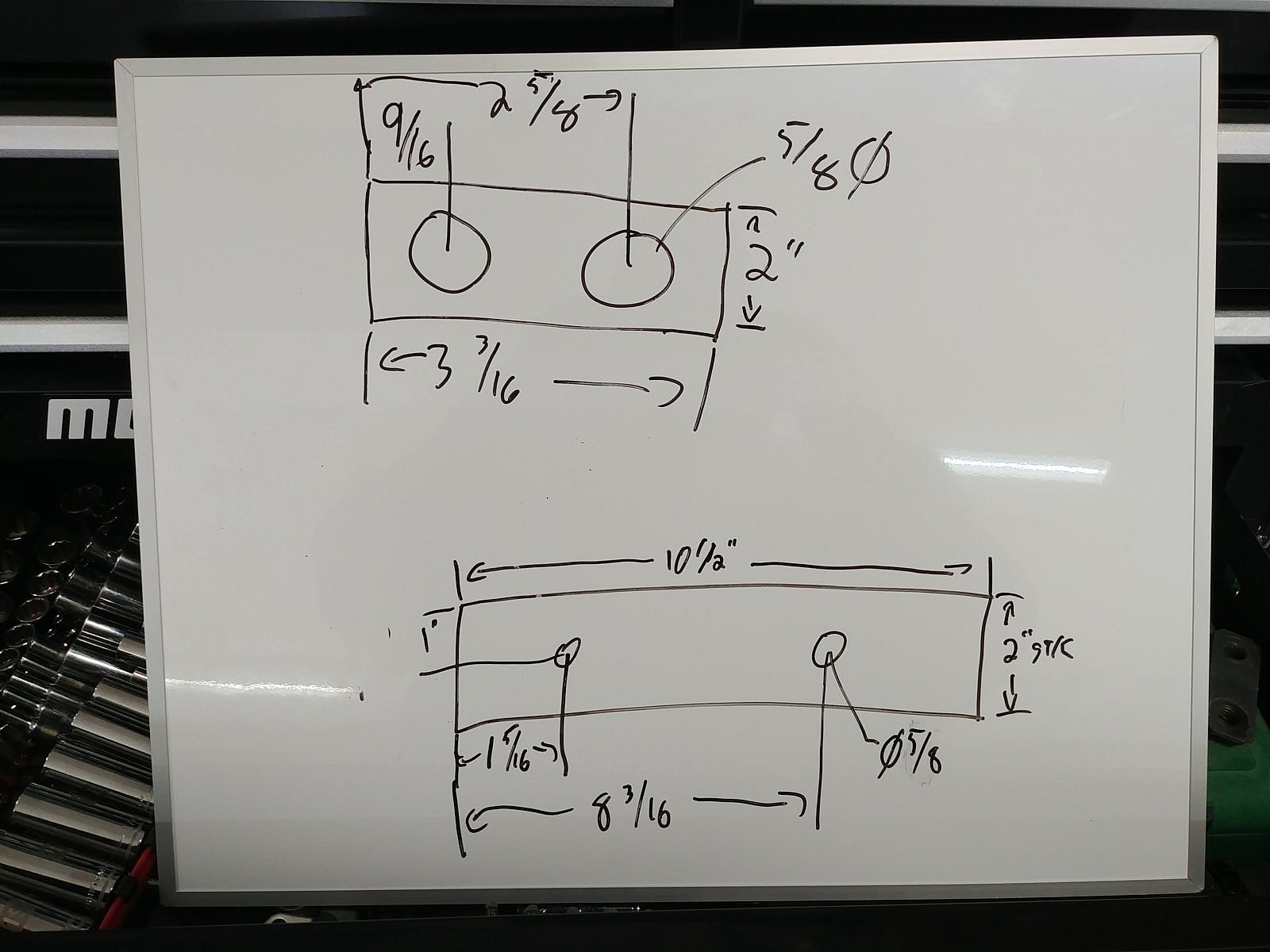

anyway, next step was making some more clearance, so i made up some k-member spacers. only had a sawzall and a hand drill, the new shop doesn't take kindly to after-hours personal projects otherwise would have done them on one of the cnc's.

otherwise would have done them on one of the cnc's.

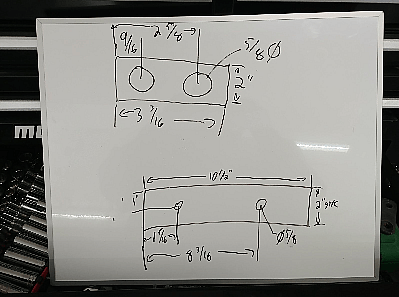

the plan:

4' of 1x2 6061, $38 at the "local" metal supply, plus another $18 for a 5/8 drill bit.

finished product (remember, sawzall and hand drill, was really wishing i had at least a band saw and a drill press...)

installed, the local hardware store only had class 8 metric bolts for the rear most mounts so ill have to order some new g8/c10.9 stuff.

anyway, next step was making some more clearance, so i made up some k-member spacers. only had a sawzall and a hand drill, the new shop doesn't take kindly to after-hours personal projects

otherwise would have done them on one of the cnc's.

otherwise would have done them on one of the cnc's. the plan:

4' of 1x2 6061, $38 at the "local" metal supply, plus another $18 for a 5/8 drill bit.

finished product (remember, sawzall and hand drill, was really wishing i had at least a band saw and a drill press...)

installed, the local hardware store only had class 8 metric bolts for the rear most mounts so ill have to order some new g8/c10.9 stuff.

also got the intake smoothed as far as i can with the arbors/tooling i can get local, needs a little more work still but good enough for a test fit. ill revisit it later, dont really want to start hogging on it cause i really have no idea wtf im doing, but need the $$ to spend on electronics and transmission over porting right now.

and got motor test fit again, this time sans headers cause im looking for hood clearance now.

spent a good half hour trying to find my damn brake booster, valve cover had to come off to get it in, but theres just enough room, that last header bolt is going to be bitch

the one big problem i have now is that the trans pan is sitting on the crossmember with about an inch of space before the mount makes contact. going to order up a stifflers piece tonight along with a few other tidbits. over the next week ill try to get the fenders and hood on to see what if anything ill have to do there.

spent a good half hour trying to find my damn brake booster, valve cover had to come off to get it in, but theres just enough room, that last header bolt is going to be bitch

the one big problem i have now is that the trans pan is sitting on the crossmember with about an inch of space before the mount makes contact. going to order up a stifflers piece tonight along with a few other tidbits. over the next week ill try to get the fenders and hood on to see what if anything ill have to do there.

I'm kind of interested about your fitment issues, i'm looking forward to your results.

Is a hydraboost system worth it for you to save space? Just curious on how tight it'll be by the brake booster with the headers on it.

Is a hydraboost system worth it for you to save space? Just curious on how tight it'll be by the brake booster with the headers on it.

Its only slightly overwhelming.Lots of work man. Gonna be a beast when done though.

Hydroboost would theoretically be an option, but I'm going manual steering so no pump. Current booster is a 93 cobra unit, so a stock booster would fit way better. Before the spacers it was sitting on the headers, so hopefully now it will clear, and maybe will get the collectors off the floor pan.I'm kind of interested about your fitment issues, i'm looking forward to your results.

Is a hydraboost system worth it for you to save space? Just curious on how tight it'll be by the brake booster with the headers on it.

Similar threads

Progress Thread

Evolution of the 'Hudson Heap' plans (87 GT)

- Replies

- 29

- Views

- 3K

- Replies

- 2

- Views

- 271

Resolved

Vibration issues

- Replies

- 11

- Views

- 1K

- Replies

- 3

- Views

- 327