You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread 1978 Mercury Cyclone. The pig is in the pen.

- Status

- Not open for further replies.

-

Sponsors (?)

I'm trying to find time in my schedule to finish wiring the 67. You're not encouraging me in the least...

BTW, I would definitely give you a cookie, if you were closer. That's a redneck masterpiece.

Sorry to rain on your parade, wiring is just a necessary evil. No real way to sugarcoat it to make it any less so.

Send the cookie along w/ the answer to "Who the hell is Hoffman-Laroche?" to;

Me

1314 Deliverance Mtn. Road

Butcher Holler, Alabama, 35244

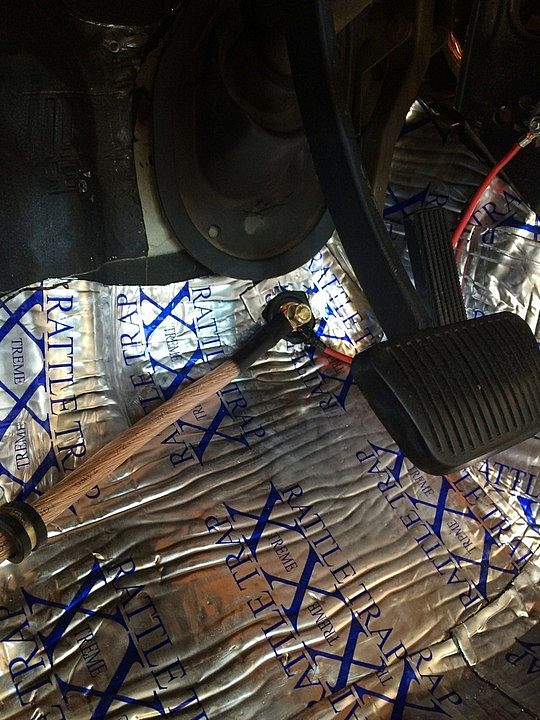

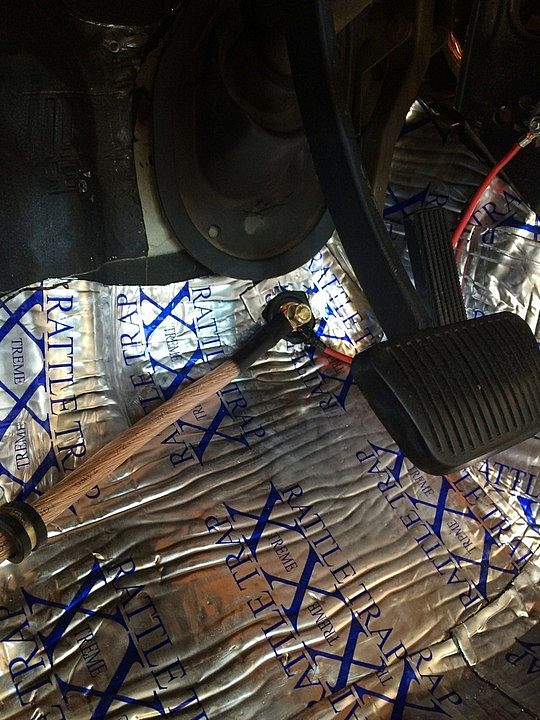

That looks like a lot of exposed connections sitting right down against that Mylar (sp) sound proof backing. No?

That looks like a lot of exposed connections sitting right down against that Mylar (sp) sound proof backing. No?

I assume you are talking about the 2 ga. under the gas pedal. They're GND's, Noobz. Pic don't show it, but they're standing off the bulkhead about 1/8th".Pic also doesn't show how once that there is carpet there, the gas pedal can't/won't touch it, and I won't likely get my foot under there to mess with it.

Now, if you have something relevant to add to my frame of thinking, that would stop me from doing something stupid, by all means.......speak up.

Otherwise, if it's because you decided I wrote "too many werdz" and didn't read the part(s) where we spoke about that ground lug, which in turn resulted in my decision to run a separate, additional 4 ga gnd for the ECU,.......then,............

Well,.......time for my humble side to show it's rare ass.

@Noobz347 pointed out a potential fault in my thinking. In my reply I decided that instead of him just being the nice guy that he might be, just trying to point out the obvious, he was mistaken, because he didn't bother to read my previous update.

That became all too obvious to me today. The grounds that will serve as the engine ground pass through a bulkhead right in front of the gas pedal. Even though they are above the layer, they are still non-insulated. My rationale for that was that they were grounds, and that I didn't have to worry about "shorting" anything.

I was testing circuits today, and in addition to a multimeter, I was using a continuity tester to do that

Everytime those two alligator clips touched the sound deadener, that POS continuity tester beeped it's ass off. I thought,.."Maybe @Noobz347 was prudent pointing out the fact that all that has to happen is one of those "dedicated" ground lugs get bent down far enough to make contact w/ that stinkin' sound deadener, and that ground just lost it's isolation.

So,.. Long story short.

You were right @Noobz347 I was ................wr....o..nggg.

There, I sucked up three times.

@Noobz347 pointed out a potential fault in my thinking. In my reply I decided that instead of him just being the nice guy that he might be, just trying to point out the obvious, he was mistaken, because he didn't bother to read my previous update.

That became all too obvious to me today. The grounds that will serve as the engine ground pass through a bulkhead right in front of the gas pedal. Even though they are above the layer, they are still non-insulated. My rationale for that was that they were grounds, and that I didn't have to worry about "shorting" anything.

I was testing circuits today, and in addition to a multimeter, I was using a continuity tester to do that

Everytime those two alligator clips touched the sound deadener, that POS continuity tester beeped it's ass off. I thought,.."Maybe @Noobz347 was prudent pointing out the fact that all that has to happen is one of those "dedicated" ground lugs get bent down far enough to make contact w/ that stinkin' sound deadener, and that ground just lost it's isolation.

So,.. Long story short.

You were right @Noobz347 I was ................wr....o..nggg.

There, I sucked up three times.

I have begun standing on my front porch and hollering "THREE O'CLOCK" on the hour every hour. Generally though, I'm right twice a day.

My neighbor for whatever reason, does not appreciate my steadfast dedication either.

My neighbor for whatever reason, does not appreciate my steadfast dedication either.

I find that there are 3 different types of people who frequent the 5.0 Talk page, where I spend a majority of my time.

1) Those with no clue (Asks questions and then disappears)

2) Those who have been doing it for a while (The Regulars)

3) Those that have an acute sense for details that categories 1 & 2 would glaze right over. (SN certified techs + Noobz)

It's very apparent who fits where with very little grey area in between. I like this, especially when those in the 3rd category debate things because everyone else learns as well.

1) Those with no clue (Asks questions and then disappears)

2) Those who have been doing it for a while (The Regulars)

3) Those that have an acute sense for details that categories 1 & 2 would glaze right over. (SN certified techs + Noobz)

It's very apparent who fits where with very little grey area in between. I like this, especially when those in the 3rd category debate things because everyone else learns as well.

The subject of ground loops is an interesting one. In theory, there will always be some voltage drop, however small, between any two different connection points in a circuit. That voltage drop will increase as current increases, as will the heat cased by the resistance. Multiple grounds will increase the possibility of ground loops. A ground loop is created when multiple grounds have different voltage drops between them and the negative ground for the car battery.

Prevailing theory is to have all grounds terminate at one location, with ground wires as short as possible and using the largest gauge wire as practical for the current load they carry. This reduces the possibility of ground loops causing a problem.

A ground loop causes problems with analog sensors because the difference in voltage across the grounds adds or subtracts to the sensor voltage seen at the sensor input on the computer. That's why you see the pin 46 dedicated signal ground on 86-95 Mustangs. All the sensors ground inside the computer using that single pin 46 ground point. The computer ground is a dedicated pair of wires that connect directly to the battery negative ground lead for the car body.

Prevailing theory is to have all grounds terminate at one location, with ground wires as short as possible and using the largest gauge wire as practical for the current load they carry. This reduces the possibility of ground loops causing a problem.

A ground loop causes problems with analog sensors because the difference in voltage across the grounds adds or subtracts to the sensor voltage seen at the sensor input on the computer. That's why you see the pin 46 dedicated signal ground on 86-95 Mustangs. All the sensors ground inside the computer using that single pin 46 ground point. The computer ground is a dedicated pair of wires that connect directly to the battery negative ground lead for the car body.

3,..2,...1,.....Ignition.

Well, to tell the truth I really don't know if I have it as of yet, but when you turn the key, stuff happens:

Clearly, Despite the spaced off, new steering wheel, I'm still gonna have to gawk around to see the outside two gauges. At this point, I'll take it as the lesser of two evils,...I'm happy w/ the notion that the engine cranks.

Underneath that gauge pod is almost a whole day of weatherpack building so I could detach that gauge cluster from the dash. All toll, there are 21 connectors under there in combinations of 2's, 3's, and 4's. I was doing great at keeping everything neat and orderly, till that requirement fouled everything up.

What it looks like "under" the gauge pod is a lot more chaotic.

Realistically, (I did say realistically) I'm really close to being able to start it. Unlike my previous "forecasts", the point I'm at now is easily 50 hours past the point where I thought I was only a few days away two weeks ago.

I still have the chassis wiring (i.e. taillights, turnsignals, headlights, that kinda junk).

And I still have all of the support mechanicals to wire (Fuel pump, cooling fans, rear heat exchangers, rear water pump).

I have to build the battery tray, and figure a way to hold it down that looks better than two J hooks holding a strap across the top of the battery. (I don't know why I'm worried about that,....I'll end up upholstering the entire rear trunk like I did the red car, and all of that stuff will be hidden anyway).

All of the above stuff aside it's the little nitpicky stuff like that continues to contaminate my progress. Leave it to me to decide to use led switches to basically switch something to ground.

I learned that w/ a led switch, you cant do that.

There should be two switches in this pic other than a bunch of disconnect. The two switches would ground the OD circuit in the trans, and the other would lock up the converter. I figured that I'd make the ground the "supply", The solenoids that needing grounding the "load", and the 12v that would light the led plugged into the lug that said "earth".

Nope. Stinkin leds are polarity sensitive. They only work one way.

Had this been a regular lighted switch, the circuit would've worked the way I described, either switching 12v to the load, or providing a gnd to the load with the light illuminating either way. problem is those switches suck, and that little bulb burns out in a minute (figuratively speaking).

So, I'll have to get creative.

Here are two more of the stupid things, only I'm not trying to do anything out of the ordinary here other than turn on the rear pump, and cooling fans.

Not without their own problems when you turn them on,....the lights are so stinkin' bright, the interior glows blue. (Blue for cool,..i.e. cooling fans, water pump). The last time there was this much blue light flooding my interior, I was getting a ticket.

You shoulda noticed that the shifter is installed. The installation of which should be another mind-numbingly simple task, except.......

My shifter sits in a little recessed trough. That through is so close to the transmission, I couldn't get a nut on a bolt to hold that shifter in to save my ass. I knew that when I built it, so I added two diagonally opposed 1/4-20 studs so as to be able to just drop that shifter onto them and zip a couple of nuts on and be done. It worked perfectly when I mocked the thing up.

It wouldn't fit worth a damn when there was a cable that stuck through the front of the trough. Again, I tested that sorry assed cable fitment when the car was in build stage, and it went together w/ no problems. Put a transmission about an inch underneath it though,.......and things get a little difficult.

I did listen to and removed the ground cables, and "insulated" them.

See, I'm not so hard headed after all.

And lastly, this brings me back to the front of the car.

From what I'm reading in the megamanual,...EDIS will run at 10 degrees in "limp home" mode. To verify that the sensor is properly placed, you unplug the PIP plug, and the thing goes into that mode. You can then put a timing light on the engine to verify that there is only 10 degrees. If not, you have to move the sensor, basically further, or closer to the tooth edge to get that right.

This little tidbit is important, because the MSII adds timing to the base 10 degrees after that. I don't know how many degrees difference there is between the front edged of the tooth, and the back edge of the tooth, but I'm pretty much in the center. I'd just as soon not have to dick with it.

See that dude down there. I don't have to tell you that once you get the radiator in there w/ the cat sucking cooling fans attached, you don't have a prayer of getting your hand up there to do jack.

That's why, I'm thinkin' of "first starting" the engine ..............dry.

Well, to tell the truth I really don't know if I have it as of yet, but when you turn the key, stuff happens:

Clearly, Despite the spaced off, new steering wheel, I'm still gonna have to gawk around to see the outside two gauges. At this point, I'll take it as the lesser of two evils,...I'm happy w/ the notion that the engine cranks.

Underneath that gauge pod is almost a whole day of weatherpack building so I could detach that gauge cluster from the dash. All toll, there are 21 connectors under there in combinations of 2's, 3's, and 4's. I was doing great at keeping everything neat and orderly, till that requirement fouled everything up.

What it looks like "under" the gauge pod is a lot more chaotic.

Realistically, (I did say realistically) I'm really close to being able to start it. Unlike my previous "forecasts", the point I'm at now is easily 50 hours past the point where I thought I was only a few days away two weeks ago.

I still have the chassis wiring (i.e. taillights, turnsignals, headlights, that kinda junk).

And I still have all of the support mechanicals to wire (Fuel pump, cooling fans, rear heat exchangers, rear water pump).

I have to build the battery tray, and figure a way to hold it down that looks better than two J hooks holding a strap across the top of the battery. (I don't know why I'm worried about that,....I'll end up upholstering the entire rear trunk like I did the red car, and all of that stuff will be hidden anyway).

All of the above stuff aside it's the little nitpicky stuff like that continues to contaminate my progress. Leave it to me to decide to use led switches to basically switch something to ground.

I learned that w/ a led switch, you cant do that.

There should be two switches in this pic other than a bunch of disconnect. The two switches would ground the OD circuit in the trans, and the other would lock up the converter. I figured that I'd make the ground the "supply", The solenoids that needing grounding the "load", and the 12v that would light the led plugged into the lug that said "earth".

Nope. Stinkin leds are polarity sensitive. They only work one way.

Had this been a regular lighted switch, the circuit would've worked the way I described, either switching 12v to the load, or providing a gnd to the load with the light illuminating either way. problem is those switches suck, and that little bulb burns out in a minute (figuratively speaking).

So, I'll have to get creative.

Here are two more of the stupid things, only I'm not trying to do anything out of the ordinary here other than turn on the rear pump, and cooling fans.

Not without their own problems when you turn them on,....the lights are so stinkin' bright, the interior glows blue. (Blue for cool,..i.e. cooling fans, water pump). The last time there was this much blue light flooding my interior, I was getting a ticket.

You shoulda noticed that the shifter is installed. The installation of which should be another mind-numbingly simple task, except.......

My shifter sits in a little recessed trough. That through is so close to the transmission, I couldn't get a nut on a bolt to hold that shifter in to save my ass. I knew that when I built it, so I added two diagonally opposed 1/4-20 studs so as to be able to just drop that shifter onto them and zip a couple of nuts on and be done. It worked perfectly when I mocked the thing up.

It wouldn't fit worth a damn when there was a cable that stuck through the front of the trough. Again, I tested that sorry assed cable fitment when the car was in build stage, and it went together w/ no problems. Put a transmission about an inch underneath it though,.......and things get a little difficult.

I did listen to and removed the ground cables, and "insulated" them.

See, I'm not so hard headed after all.

And lastly, this brings me back to the front of the car.

From what I'm reading in the megamanual,...EDIS will run at 10 degrees in "limp home" mode. To verify that the sensor is properly placed, you unplug the PIP plug, and the thing goes into that mode. You can then put a timing light on the engine to verify that there is only 10 degrees. If not, you have to move the sensor, basically further, or closer to the tooth edge to get that right.

This little tidbit is important, because the MSII adds timing to the base 10 degrees after that. I don't know how many degrees difference there is between the front edged of the tooth, and the back edge of the tooth, but I'm pretty much in the center. I'd just as soon not have to dick with it.

See that dude down there. I don't have to tell you that once you get the radiator in there w/ the cat sucking cooling fans attached, you don't have a prayer of getting your hand up there to do jack.

That's why, I'm thinkin' of "first starting" the engine ..............dry.

- Dec 19, 2010

- 5,719

- 4,238

- 224

Meh. Pull the wire on the ignition and crank it till it primes. She'll be ok. You used assembly lube, right?

Meh. Pull the wire on the ignition and crank it till it primes. She'll be ok. You used assembly lube, right?

I already primed the thing w/ a drill (90 psi, remember?) I'm taking about starting it w/o the radiator in place.

- Dec 19, 2010

- 5,719

- 4,238

- 224

I already primed the thing w/ a drill (90 psi, remember?) I'm taking about starting it w/o the radiator in place.

Oooh ok. Missed it, sorry. I remember eluding to doing that.. but didn't catch it being executed. Probably was sanding.

You sure you want to start it w/o coolant? Just to hear it crank, right?

Oooh ok. Missed it, sorry. I remember eluding to doing that.. but didn't catch it being executed. Probably was sanding.

You sure you want to start it w/o coolant? Just to hear it crank, right?

Nope,....talking about running it long enough to get a timing light on it w/ pip disconnected..

That is of course after it runs well enough to even worry about whether or not EDIS is not set properly.

Maybe I'll put rad in place, get it started, and running right. After that, I'll pull pip plug and ck timing. If I have to adjust,...I'll remove rad, restart it long enough to adjust the sensor placement, (if I even have to).

Yeah, that gauge pod is so front heavy, it will tip over w/o it.What is the little "Box" between the Gauge Pod and Steering Column? Temporary Support?

3,..2,...1,.....Ignition.

Well, to tell the truth I really don't know if I have it as of yet, but when you turn the key, stuff happens:

Speaking of which, what do you s'pose is going on "under" the steering column cover? Is this an opto illusion ya think?

Are you referring to the brake pedal that seems to be close and centered enough to the seat that it can be operated with the proverbial 'third leg'?Speaking of which, what do you s'pose is going on "under" the steering column cover? Is this an opto illusion ya think?

No, the weird orange glow coming from under the cover.Are you referring to the brake pedal that seems to be close and centered enough to the seat that it can be operated with the proverbial 'third leg'?

- Status

- Not open for further replies.