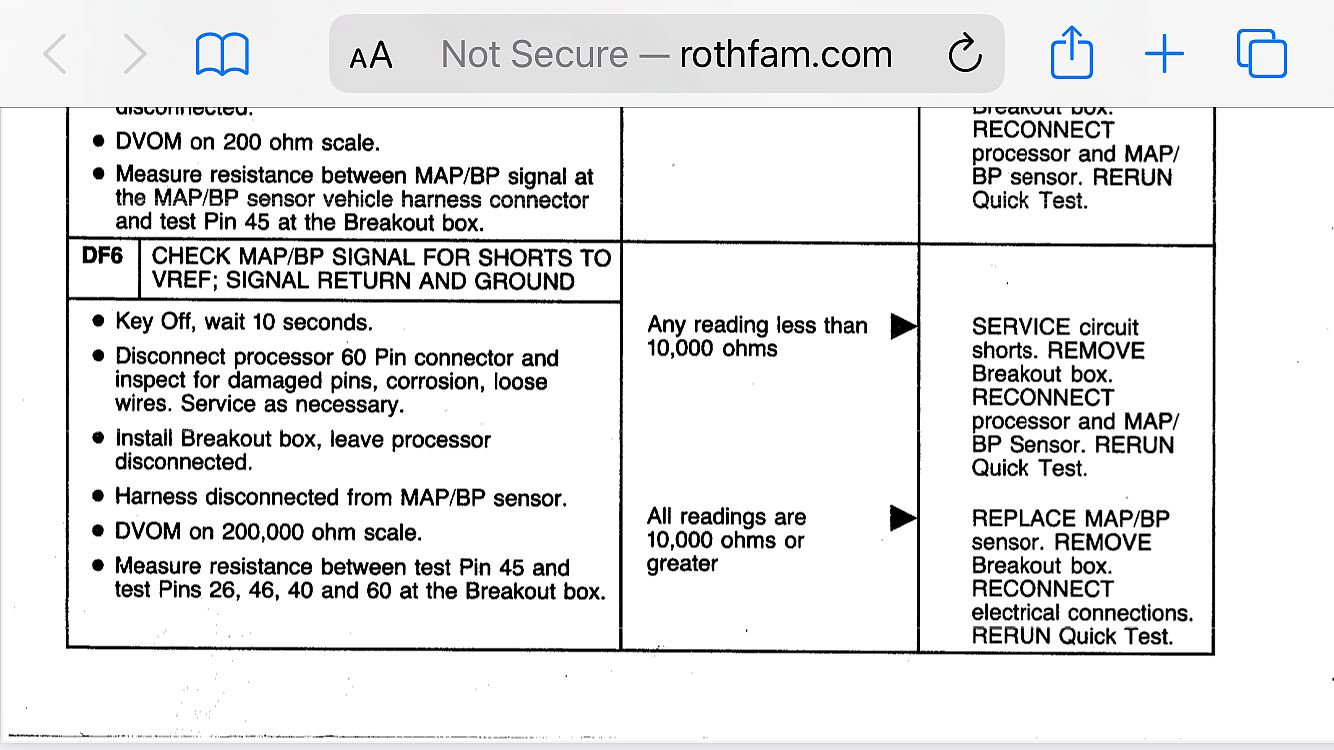

This is another resource I’m using. All the way down to page 33 it starts getting into needing the breakout box.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Resolved Cranks but still doesn’t start. Ran through the checklist and still doesn’t start.

- Thread starter reddy351

- Start date

Threads that have been [Resolved] by the OP or Moderator

-

Sponsors (?)

On THIS test, it measures 10.0 ohms. The book tells me that if it’s over 5 ohms to repair “opens” in the circuit.

Be back soon…

Be back soon…

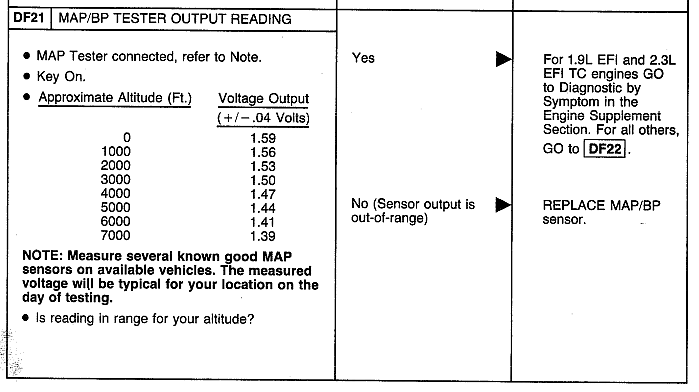

I fixed the wiring and now both of the BP sensors read 2.69 and 2.66 V respectively. Seems to be a BP sensor, now.This one seems similar to how the Textrom 127 tests

Replaced the BP Sensor and NO MORE CODE 22.

But it will still barely idle. BP Sensor signal wire still reads 2.69v.

On to the next thing, I guess.

But it will still barely idle. BP Sensor signal wire still reads 2.69v.

On to the next thing, I guess.

Last edited:

Considering the car now has a BP signal to work off, i would start from scratch now.

Base idle reset, fuel pressure, timing, etc. Also wouldnt hurt to smoke test and verify no vac leaks. Get a few drives in and pull engine running and engine off codes and perhaps the cylinder balance test.

Base idle reset, fuel pressure, timing, etc. Also wouldnt hurt to smoke test and verify no vac leaks. Get a few drives in and pull engine running and engine off codes and perhaps the cylinder balance test.

Well, it won’t idle enough to set base idle. FP is 38psi. Timing is set “straight-up with the #1 piston at TDC on the compression stroke and the rotor pointed directly at the contact for the #1 plug wire. That should at least get it close enough to start.

I have discovered the checklist thread for a 5.0 that cranks but won’t start. I guess I’ll start at the beginning, the next time I get a chance to work on it.

Here’s what I’ve checked/done so far:

Brand new Painless wiring harness

Fuel pump primes when KO

Fuel pressure-38psi KOEO

Fuel lines are connected correctly

Timing is correct

Firing order is correct

TPS measures .97v

Proper voltages at coil

Coil tests ok

Had a “22” code that I resolved

Replaced Baro Pressure sensor

Clutch pressure switch code (67)

EGR is deleted/blocked—those codes

Swapped A9L for “known good” unit

Swapped 30# injectors/aftermarket MAF for 19# injectors/stock MAF

If swapping drivelines was easy, everyone would be doing it.

I have discovered the checklist thread for a 5.0 that cranks but won’t start. I guess I’ll start at the beginning, the next time I get a chance to work on it.

Here’s what I’ve checked/done so far:

Brand new Painless wiring harness

Fuel pump primes when KO

Fuel pressure-38psi KOEO

Fuel lines are connected correctly

Timing is correct

Firing order is correct

TPS measures .97v

Proper voltages at coil

Coil tests ok

Had a “22” code that I resolved

Replaced Baro Pressure sensor

Clutch pressure switch code (67)

EGR is deleted/blocked—those codes

Swapped A9L for “known good” unit

Swapped 30# injectors/aftermarket MAF for 19# injectors/stock MAF

If swapping drivelines was easy, everyone would be doing it.

Last edited:

Did you swap in 19 lb/hr injectors? MAF calibrated for 30 lb/hr injectors works good with 30 lb/hr injectors installed but a stock MAF calibrated for 19 lb/hr injectors with 30 lb/hr injectors installed will run like ass.

Nope. I swapped the 19# injectors AND the stock MAF that's made to work with them. I figure putting everything I can back to "stock" is a good baseline for the diagnostic process. (I should have never thought I could start with bigger injectors and aftermarket MAF to begin with.)

I can switch them back, once I get this figured out.

In this process, when trying to set the TPS, the voltage was extremely high when testing to Ground. When I probed the "Sig Return" (blk/wht wire) on the TPS, it was well within the proper voltage range and was very easy to set at .97v. That LOOKS like a grounding issue with the computer but the grounds for the EEC are connected to the location that the previous computer was grounded and I do have plenty of ground straps on the engine to body.

Can I connect the blk/wht wire to ground temporarily to see if that changes anything?

I can switch them back, once I get this figured out.

In this process, when trying to set the TPS, the voltage was extremely high when testing to Ground. When I probed the "Sig Return" (blk/wht wire) on the TPS, it was well within the proper voltage range and was very easy to set at .97v. That LOOKS like a grounding issue with the computer but the grounds for the EEC are connected to the location that the previous computer was grounded and I do have plenty of ground straps on the engine to body.

Can I connect the blk/wht wire to ground temporarily to see if that changes anything?

Last edited:

TPS doesn't need to be 0.97V. That's just a myth. Acceptable range is 0.51V to 1.24V. Anything in there is perfectly fine. Upon startup that ECU takes a baseline idle reading and assigns that as a variable x indicating closed throttle. It then assigned a value to add to that number (I think it's 3.5V but not 100% sure) that indicates WOT.

Really you should be less focused on what the idle voltage is, and more focused on if the TPS voltage sweeps properly from idle to WOT. Nothing wrong with setting it to 1V, but don't lose sleep if it's 1.05V that's still good. Ford just slapped these sensors on and didn't calibrate anything. If they are out of range, they generate a code.

ANyway, code 67 is regarding not pressing the clutch in, or having the T5 in neutral. The painless kit may not have the provisions to connect to the clutch switch and the sensor on the top of the T5. If not, you may need to work-around this somewhat. It has a slight impact on idle quality, but don't think that is what is going on here.

BTW, you are running the codes with engine off AND with engine on correct? Have you done the cylinder balance test at the end of the code reading procedure?

Really you should be less focused on what the idle voltage is, and more focused on if the TPS voltage sweeps properly from idle to WOT. Nothing wrong with setting it to 1V, but don't lose sleep if it's 1.05V that's still good. Ford just slapped these sensors on and didn't calibrate anything. If they are out of range, they generate a code.

ANyway, code 67 is regarding not pressing the clutch in, or having the T5 in neutral. The painless kit may not have the provisions to connect to the clutch switch and the sensor on the top of the T5. If not, you may need to work-around this somewhat. It has a slight impact on idle quality, but don't think that is what is going on here.

BTW, you are running the codes with engine off AND with engine on correct? Have you done the cylinder balance test at the end of the code reading procedure?

Engine on? There IS no engine on. Thats the purpose of this post. It will not idle on its own. At all. I have to modulate the accelerator just to get it to stay running.

So, no, all of the codes I have are KOEO as that’s the only state that’s anywhere near reliable.

As far as setting the TPS, it was well out of the range you mentioned until I drilled out the mounting holes a little. After that, the best I achieved was 1.07v, using the negative battery post. When I used the “Sig Return” wire, I was able to get anywhere in the range that you mentioned. I simply set it where common knowledge says to set it. I just happened to set it at .97v.

So, no, all of the codes I have are KOEO as that’s the only state that’s anywhere near reliable.

As far as setting the TPS, it was well out of the range you mentioned until I drilled out the mounting holes a little. After that, the best I achieved was 1.07v, using the negative battery post. When I used the “Sig Return” wire, I was able to get anywhere in the range that you mentioned. I simply set it where common knowledge says to set it. I just happened to set it at .97v.

Last edited:

The “67” code is the Neutral Start Switch. It actually has nothing to do with keeping the car from starting when the clutch isn’t engaged. It has more to do with the load on the engine when coasting down to a stop. Without it, the engine revs-up to keep the engine from stalling at low rpm’s. It also will not allow KOER tests as a safety to keep people from testing their automatic car in gear, since the KOER takes control of the engine rpm’s as part of the test. Don’t want Billy Bob’s Stanger to drive itself through the barn wall while running a diagnostic. Lol.

I really do appreciate your help in trying to get this running.

I really do appreciate your help in trying to get this running.

Sorry, I was under the impression you were able to start the car, albeit with it running poorly. But we’ll enough to maybe pull the engine running codes

No sir. I’m still trying to attain that.

I pulled the codes on the replacement computer today. I get the same ones. So, apparently it’s not the computer.

I pulled the codes on the replacement computer today. I get the same ones. So, apparently it’s not the computer.

Not tedious at all. I have them in my notes on my phone. Lol. This was done on a sub-50 degree day and the 21 and 24 are new (likely) because of that. The 31 is “new” because I unplugged the EGR eliminator that I had bought and put in there, to see if it made any difference. (It didn’t.)

21–ECT out of range

24–ACT out of range

31–EVP below min voltage

67–NPS failure

81–Air Diverter Solenoid fault

82–Air Diverter Solenoid fault

85–Canister Purge Solenoid failure

84–EGR vacuum circuit failure

21–ECT out of range

24–ACT out of range

31–EVP below min voltage

67–NPS failure

81–Air Diverter Solenoid fault

82–Air Diverter Solenoid fault

85–Canister Purge Solenoid failure

84–EGR vacuum circuit failure

Here it is, trying to start.

It does have a nice, bright spark that can easily be seen in direct sunlight.

The next step in the process is to spray some ether in it.

Edit: Will NOT start on ether.

Edit 2: Compression:

1–115psi

2–117psi

3–117psi

4–122psi

5–119psi

6–127psi

7–120psi

8–108psi

It does have a nice, bright spark that can easily be seen in direct sunlight.

The next step in the process is to spray some ether in it.

Edit: Will NOT start on ether.

Edit 2: Compression:

1–115psi

2–117psi

3–117psi

4–122psi

5–119psi

6–127psi

7–120psi

8–108psi

Last edited:

I have a good one for you. After going through the “Cranks but no start” checklist, this is my result:

—Has nice bright spark that you can see in direct sunlight.

—Can hear the fuel pump priming for 2-4 seconds.

—When distributor is twisted in its hole, you can hear the fuel pump run again. (PIP is ok)

—Will not run with ether/starting fluid.

—Fuel pressure is 38psi.

—Noid light indicates injectors are getting their signal.

—Standalone harness. No s&p shakers.

—TPS set at .97v

—Firing order is correct.

—Distributor is stabbed correctly.

—Swapped computer with a known good one.

—Compression is as follows:

1–115psi

2–117psi

3–117psi

4–122psi

5–119psi

6–127psi

7–120psi

8–108psi

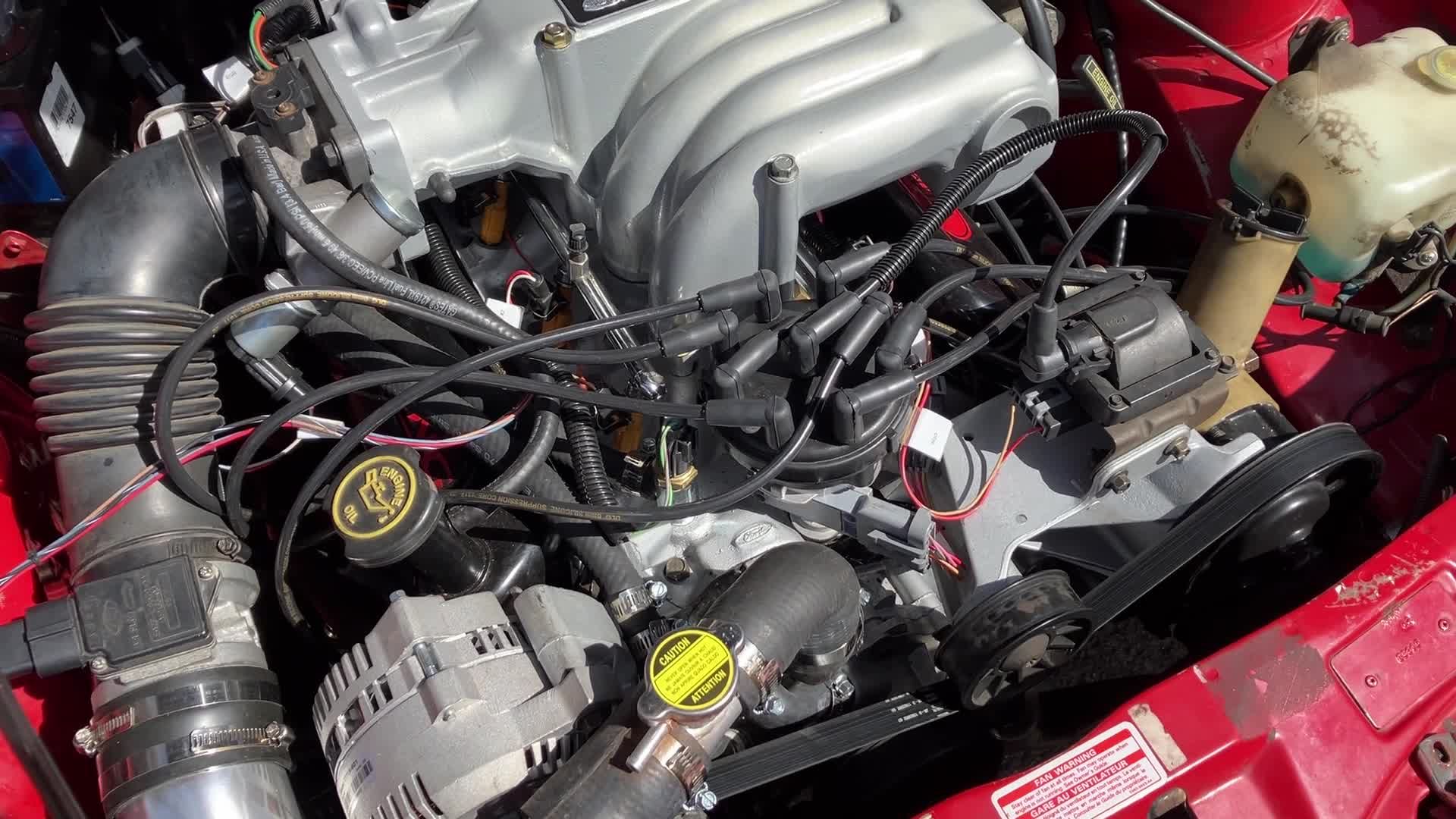

This is a fresh rebuild and has zero miles. Stock cam, AFR “Enforcer” heads, Cobra intake, 19# injectors and stock MAF. Using an A9L computer. It has a Walbro 255lph fuel pump that was fueling the turbo 2.3 six weeks ago.

What do I check next?

—Has nice bright spark that you can see in direct sunlight.

—Can hear the fuel pump priming for 2-4 seconds.

—When distributor is twisted in its hole, you can hear the fuel pump run again. (PIP is ok)

—Will not run with ether/starting fluid.

—Fuel pressure is 38psi.

—Noid light indicates injectors are getting their signal.

—Standalone harness. No s&p shakers.

—TPS set at .97v

—Firing order is correct.

—Distributor is stabbed correctly.

—Swapped computer with a known good one.

—Compression is as follows:

1–115psi

2–117psi

3–117psi

4–122psi

5–119psi

6–127psi

7–120psi

8–108psi

This is a fresh rebuild and has zero miles. Stock cam, AFR “Enforcer” heads, Cobra intake, 19# injectors and stock MAF. Using an A9L computer. It has a Walbro 255lph fuel pump that was fueling the turbo 2.3 six weeks ago.

What do I check next?

Last edited:

Similar threads

Electrical

Codes

- Replies

- 4

- Views

- 1K

- Replies

- 6

- Views

- 1K

- Replies

- 13

- Views

- 765

- Replies

- 5

- Views

- 1K

- Replies

- 25

- Views

- 2K