Thank you for the encouragement! I hope to put some miles on it to verify everything.Right on man, maybe you can have some fun with it now. Good job.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread Nasty Ninety Notch

- Thread starter joetrainer31

- Start date

-

Sponsors (?)

Update: Too Hot?

Test drove the car today (i.e., ran errands). Its about 90ish in SoCal today. I noticed that after driving and sitting at idle with the A/C on that the temp still goes 1/2 a notch above dead middle. In other words, the temp indicator goes between the middle line and the next line up from the middle. If I start driving it will immediately drop back to the middle and down to the next line below that if I drive enough and the thermostat opens. Additionally, if I turn the A/C off while the indicator is at that 1/2 way mark between the middle and next line the temp will slowly creep down to the middle if I remain at idle.

The Question: Does this idle temp seem fine? What are your car's idle temps like? There are LOTS of opportunities to sit in traffic here in SoCal.

The Set-Up: My cooling system consists of an SVE 3 core radiator, new Ford 192* stat, new hoses, heater core is functional, new factory water pump, new oem fan and fan clutch, new overflow, factory pulleys, new 50/50 antifreeze, and new temp sensor & sender. Ford X307 aluminum heads.

My A/C system is all brand new. It is converted to run R134a.

Thoughts?

Test drove the car today (i.e., ran errands). Its about 90ish in SoCal today. I noticed that after driving and sitting at idle with the A/C on that the temp still goes 1/2 a notch above dead middle. In other words, the temp indicator goes between the middle line and the next line up from the middle. If I start driving it will immediately drop back to the middle and down to the next line below that if I drive enough and the thermostat opens. Additionally, if I turn the A/C off while the indicator is at that 1/2 way mark between the middle and next line the temp will slowly creep down to the middle if I remain at idle.

The Question: Does this idle temp seem fine? What are your car's idle temps like? There are LOTS of opportunities to sit in traffic here in SoCal.

The Set-Up: My cooling system consists of an SVE 3 core radiator, new Ford 192* stat, new hoses, heater core is functional, new factory water pump, new oem fan and fan clutch, new overflow, factory pulleys, new 50/50 antifreeze, and new temp sensor & sender. Ford X307 aluminum heads.

My A/C system is all brand new. It is converted to run R134a.

Thoughts?

Last edited:

mikestang63

SN Certified Technician

1. factory gauges are nothing more than idiot lights with lines on them

2. make sure the system is burped of all air

3. get a real water tamp gauge and see what the temp is

4. aluminum heads do not control the heat as well as cast iron heads

5. As long as the temp stays 210 or less you are ok. engines run better when hotter to a certain extent

2. make sure the system is burped of all air

3. get a real water tamp gauge and see what the temp is

4. aluminum heads do not control the heat as well as cast iron heads

5. As long as the temp stays 210 or less you are ok. engines run better when hotter to a certain extent

Mike, thanks so much for the helpful feedback. The system is burped of air. Besides drilling an extra hole at 12 o'clock on the stat I have a system for burping the cooling system.1. factory gauges are nothing more than idiot lights with lines on them

2. make sure the system is burped of all air

3. get a real water tamp gauge and see what the temp is

4. aluminum heads do not control the heat as well as cast iron heads

5. As long as the temp stays 210 or less you are ok. engines run better when hotter to a certain extent

As far as the aluminum heads go, I was thinking that they controlled heat better by dissipation and because they resist detonation better than cast iron. I guess I was mistaken, very interesting. I'll see about a real gauge.

I think he means that aluminum is less "consistent" w/ regard to heat dissipation. Aluminum heads move heat very quickly to the water, vs a cast iron head which will maintain it's temp more consistently despite the water touching it. Aluminum gets hot very quickly, and can cool equally fast when another source for conduction moves in to act upon it.Mike, thanks so much for the helpful feedback. The system is burped of air. Besides drilling an extra hole at 12 o'clock on the stat I have a system for burping the cooling system.

As far as the aluminum heads go, I was thinking that they controlled heat better by dissipation and because they resist detonation better than cast iron. I guess I was mistaken, very interesting. I'll see about a real gauge.

Thank you, Mike. That's helpful. I'm just trying to understand the difference between cast & aluminum. This is actually the first set of aluminum heads I've used.I think he means that aluminum is less "consistent" w/ regard to heat dissipation. Aluminum heads move heat very quickly to the water, vs a cast iron head which will maintain it's temp more consistently despite the water touching it. Aluminum gets hot very quickly, and can cool equally fast when another source for conduction moves in to act upon it.

I think he means that aluminum is less "consistent" w/ regard to heat dissipation. Aluminum heads move heat very quickly to the water, vs a cast iron head which will maintain it's temp more consistently despite the water touching it. Aluminum gets hot very quickly, and can cool equally fast when another source for conduction moves in to act upon it.

Aluminum conducts heat 4.5- 6.8 times better that iron at temperatures encountered in typical automotive use. See http://www.engineeringtoolbox.com/thermal-conductivity-metals-d_858.html

So it seems that would explain why the temp (on stock gauge) still goes above the middle even with a 3 row radiator. Right? Am I just being overly concerned then?Aluminum conducts heat 4.5- 6.8 times better that iron at temperatures encountered in typical automotive use. See http://www.engineeringtoolbox.com/thermal-conductivity-metals-d_858.html

Update: Headliners and Ford OEM "insulation."

I've had a TMI replacement headliner from LMR sitting in the living room for about a year now. I figured it was time to finally R&R the headliner. If anyone is interested on how to do it and/or what you may encounter see below...

The original (26 y.o.) headliner had a lot of grease on it. Although, no sagging, and only a couple of minor tears. Yet, I was more concerned about what was above the liner as the brownish/orange stuff kept falling down by my door's scuff plate.

Here is a before pic of the restored & super clean interior...wait for it...

First step, take the seats out for room to work...

Pop off the trim above the doors...

Next, remove the sun visors...

Next, remove the map light (which never works), if equipped...

Then, remove the roof/windshield trim in the middle by popping it off just like the trim above each door (fingers, flat head screw driver, or claw tool will work)...

Next, remove the A pillar trim (on both sides). There are 3 screws total. It might help in extracting the bottom screw if you remove the dash speaker cover...

Next, remove the seat belt bolt cover with a flat head...

Then, the seat belt itself is removed. Just let it fall where it may...

See next entry for continuation...

I've had a TMI replacement headliner from LMR sitting in the living room for about a year now. I figured it was time to finally R&R the headliner. If anyone is interested on how to do it and/or what you may encounter see below...

The original (26 y.o.) headliner had a lot of grease on it. Although, no sagging, and only a couple of minor tears. Yet, I was more concerned about what was above the liner as the brownish/orange stuff kept falling down by my door's scuff plate.

Here is a before pic of the restored & super clean interior...wait for it...

First step, take the seats out for room to work...

Pop off the trim above the doors...

Next, remove the sun visors...

Next, remove the map light (which never works), if equipped...

Then, remove the roof/windshield trim in the middle by popping it off just like the trim above each door (fingers, flat head screw driver, or claw tool will work)...

Next, remove the A pillar trim (on both sides). There are 3 screws total. It might help in extracting the bottom screw if you remove the dash speaker cover...

Next, remove the seat belt bolt cover with a flat head...

Then, the seat belt itself is removed. Just let it fall where it may...

See next entry for continuation...

Last edited:

Update: Headliners and Ford OEM "insulation," Con't

After the seat belts are removed, remove the rear roof trim by popping it off just like the side and front pieces...

Next, loosen all 6 screws (for a coupe) to the rear quarter trim on each side. If you are working alone, as I was, you will only want the trim to be manipulatable, not removed. When you install the new headliner the trim will act like another set of hands to support the liner as you try to position it properly...

Next, remove all 3 retaining clips using a trim tab removal tool of flat head (1 at each side and 1 in the rear). Be careful not to ruin them unless you have replacements...

Next, unscrew the interior light. At this point this light is the remaining piece hold up the liner...

Next, remember how your nice, cleaned, and restored interior looked...

Because the liner will fall and this will happen. This is the "insulation" Ford used in our cars. It used to be stuck to cheap looking Walmart style single ply black garbage bags which itself was held up by some kind of adhesive. Once the liner starts to move the roof will take a crap on your interior...

This is what you will need to remove. I suggest wearing eye protection, a mask, and gloves. There is no telling what has been growing up there for 26 years...

More devastation after scraping and cleaning roof with alcohol...

Yep, even this side got wrecked. Basically the entire interior will be a heartbreaker for clean-minded guys...

To be continued...

After the seat belts are removed, remove the rear roof trim by popping it off just like the side and front pieces...

Next, loosen all 6 screws (for a coupe) to the rear quarter trim on each side. If you are working alone, as I was, you will only want the trim to be manipulatable, not removed. When you install the new headliner the trim will act like another set of hands to support the liner as you try to position it properly...

Next, remove all 3 retaining clips using a trim tab removal tool of flat head (1 at each side and 1 in the rear). Be careful not to ruin them unless you have replacements...

Next, unscrew the interior light. At this point this light is the remaining piece hold up the liner...

Next, remember how your nice, cleaned, and restored interior looked...

Because the liner will fall and this will happen. This is the "insulation" Ford used in our cars. It used to be stuck to cheap looking Walmart style single ply black garbage bags which itself was held up by some kind of adhesive. Once the liner starts to move the roof will take a crap on your interior...

This is what you will need to remove. I suggest wearing eye protection, a mask, and gloves. There is no telling what has been growing up there for 26 years...

More devastation after scraping and cleaning roof with alcohol...

Yep, even this side got wrecked. Basically the entire interior will be a heartbreaker for clean-minded guys...

To be continued...

Last edited:

Update:Headliners and Ford OEM "insulation," Con't, Again

Now, the roof is cleaned properly. There is still some factory adhesive left, but it's stuck on there so good that its not coming off even with...

Stinger Roadkill applied! Make sure to invest in a quality roller so that you can really smash this stuff on good. Roadkill comes in a box as 3 sheet packs. On our cars you can simply start on one side of the car, slide the end of one pack as far over as you can get it, and hand smash/roll the rest of the 3 sheets out toward the other side. Its length is about 1/2 sheet too short so simply cut one section of the 3 sheets off, then cut that one in 1/2 to make up the difference. I think it was @hoopty5.0 who turned me onto this stuff...

Next, do the same for the rear...

Next, after all the new insulation/sound deadener is applied (and yes, it sticks just fine to a vertical surface), promptly place the TMI headliner where it belongs, in the DUMPSTER! After placing this liner up I struggled for hours trying to reinstall the interior trim and line up the sun visors. I could never get the trim to line up so that all the screws could go back in. Also, I could not get the sunvisors to line up either. The reason, this is a crap liner from TMI. The casting holes in the plastic aren't even close for lining up the visors. Furthermore, it's too wide for the car by about 1 & 1/2 inches, and believe me, that makes a difference. Its trash and for $250 its money NOT well spent. It is also time NOT well spent because I didn't realize the level of bad this liner was at until I had worked all the way forward to the visors. Basically, I had to reverse everything and do the job twice.

Lastly, take your OEM liner out of said dumpster where the TMI unit resides, clean it, and reinstall it. Guys, the difference in fit is night and day! This liner practically fell in place and all the screws went back into the trim. It was as if I couldn't miss the screw holes behind the trim. The visors were a bit more challenging, but not IMPOSSIBLE like with the TMI unit. The OEM fit is far superior to the TMI unit.

I could really tell a difference in heat reduction and sound insulation with the Roadkill on the roof. It's good stuff. After the job is done just detail the interior and you're good.

Now, the roof is cleaned properly. There is still some factory adhesive left, but it's stuck on there so good that its not coming off even with...

Stinger Roadkill applied! Make sure to invest in a quality roller so that you can really smash this stuff on good. Roadkill comes in a box as 3 sheet packs. On our cars you can simply start on one side of the car, slide the end of one pack as far over as you can get it, and hand smash/roll the rest of the 3 sheets out toward the other side. Its length is about 1/2 sheet too short so simply cut one section of the 3 sheets off, then cut that one in 1/2 to make up the difference. I think it was @hoopty5.0 who turned me onto this stuff...

Next, do the same for the rear...

Next, after all the new insulation/sound deadener is applied (and yes, it sticks just fine to a vertical surface), promptly place the TMI headliner where it belongs, in the DUMPSTER! After placing this liner up I struggled for hours trying to reinstall the interior trim and line up the sun visors. I could never get the trim to line up so that all the screws could go back in. Also, I could not get the sunvisors to line up either. The reason, this is a crap liner from TMI. The casting holes in the plastic aren't even close for lining up the visors. Furthermore, it's too wide for the car by about 1 & 1/2 inches, and believe me, that makes a difference. Its trash and for $250 its money NOT well spent. It is also time NOT well spent because I didn't realize the level of bad this liner was at until I had worked all the way forward to the visors. Basically, I had to reverse everything and do the job twice.

Lastly, take your OEM liner out of said dumpster where the TMI unit resides, clean it, and reinstall it. Guys, the difference in fit is night and day! This liner practically fell in place and all the screws went back into the trim. It was as if I couldn't miss the screw holes behind the trim. The visors were a bit more challenging, but not IMPOSSIBLE like with the TMI unit. The OEM fit is far superior to the TMI unit.

I could really tell a difference in heat reduction and sound insulation with the Roadkill on the roof. It's good stuff. After the job is done just detail the interior and you're good.

Last edited:

Yes, I plan to do that. I was going to do it all same day, but since I had to do the liner job twice, due to crap LMR product, I was too tired.Are you going to install the roadkill mat under the carpet?

Update: Floored, Cool, and Silent.

I figured since the roof had insulation that I'd check out the floor and see how it was doing.

Remove those pesky seats as you will be ripping up carpet today!

Next, remove the scuff plates. Although, in hind sight, I would remove the plates before the seats as I scraped mine and had to repaint after the job was done...

Remove the arm rest by loosening the 4 bolts (2 each side), then simply pull up on the rest.

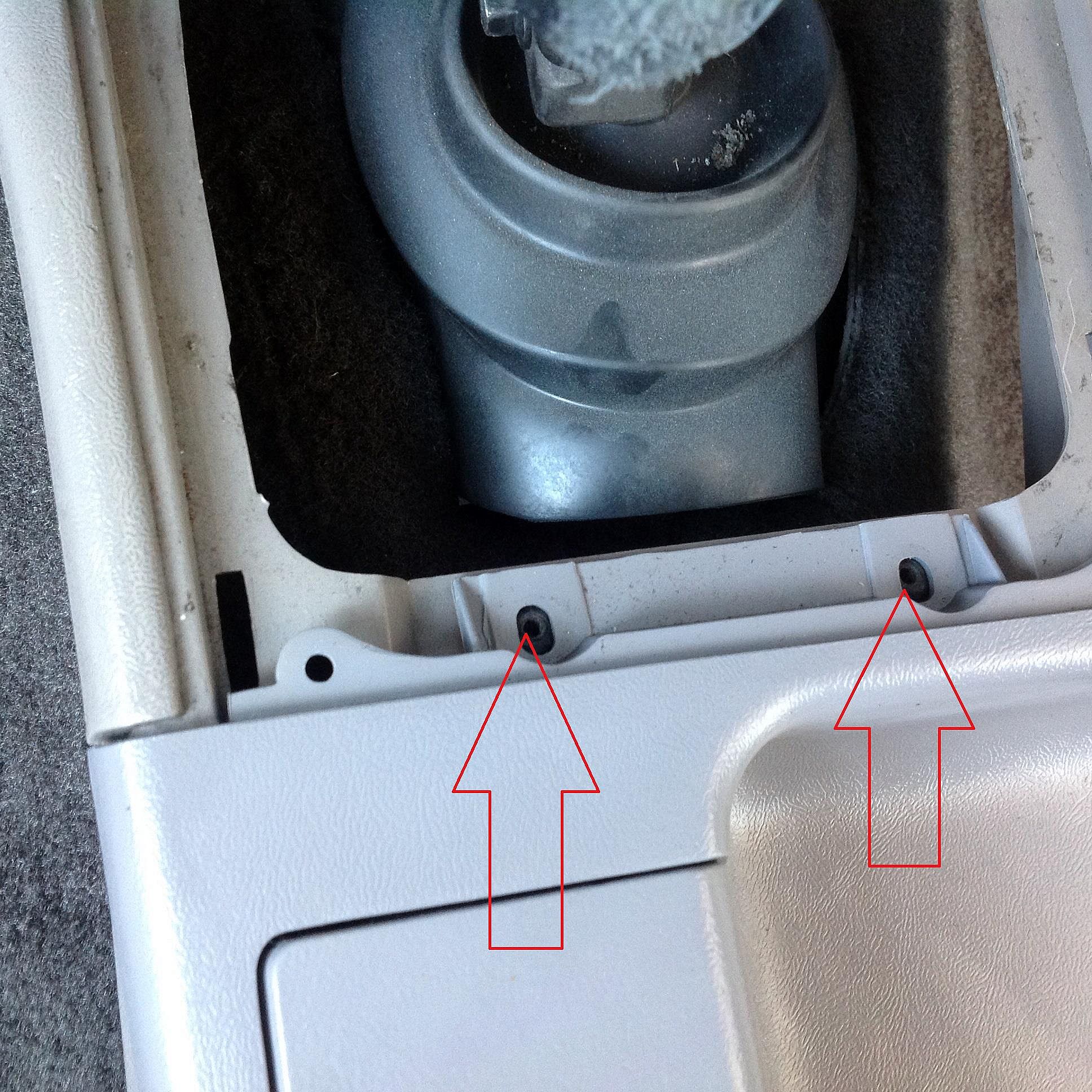

For console top plate remove 2 screws at it's rear...

Then 2 screws at it's front.

Before pulling up too hard on the top plate make sure to disconnect any pigtails.

Remove A/C bezel and shifter handle.

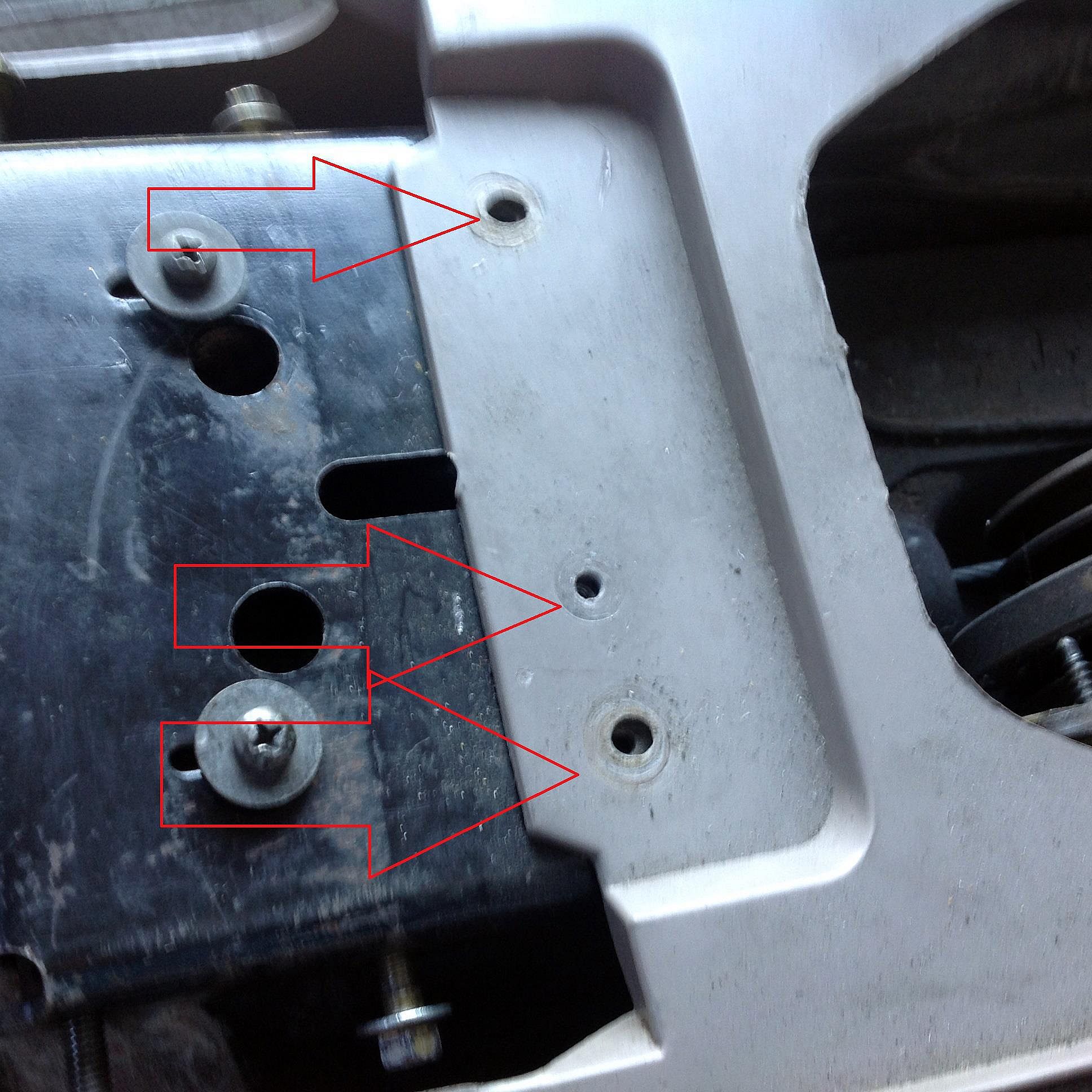

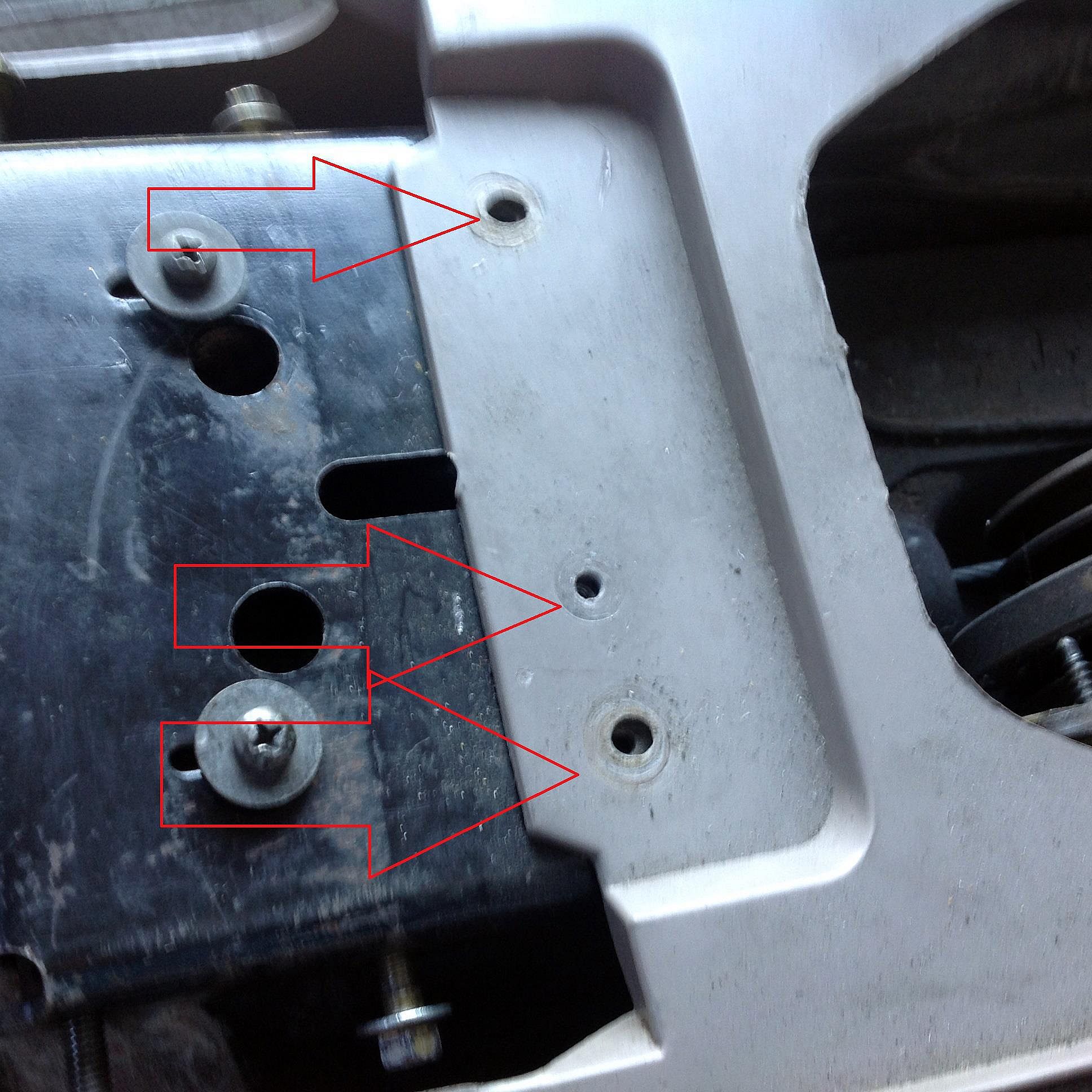

Remove 2 torx screws on the right side of the console. Drop the glovebox down for better access by simply pulling the box's release tabs in. Also, don't forget to unplug the trunk pigtail.

Remove the covering that surrounds the steering column by loosening 2 recessed Phillip's head screws. This will allow access to the left side center console torx screws.

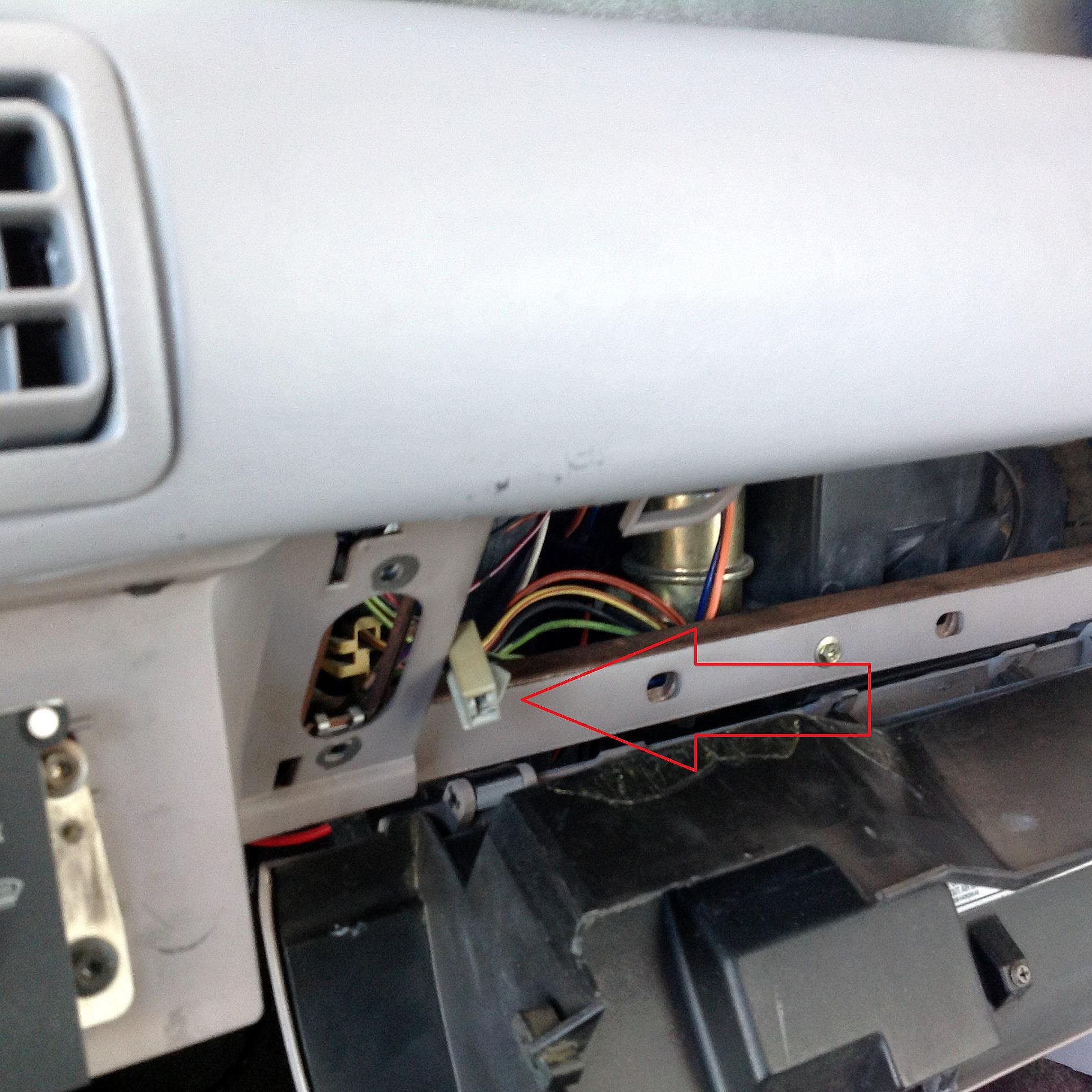

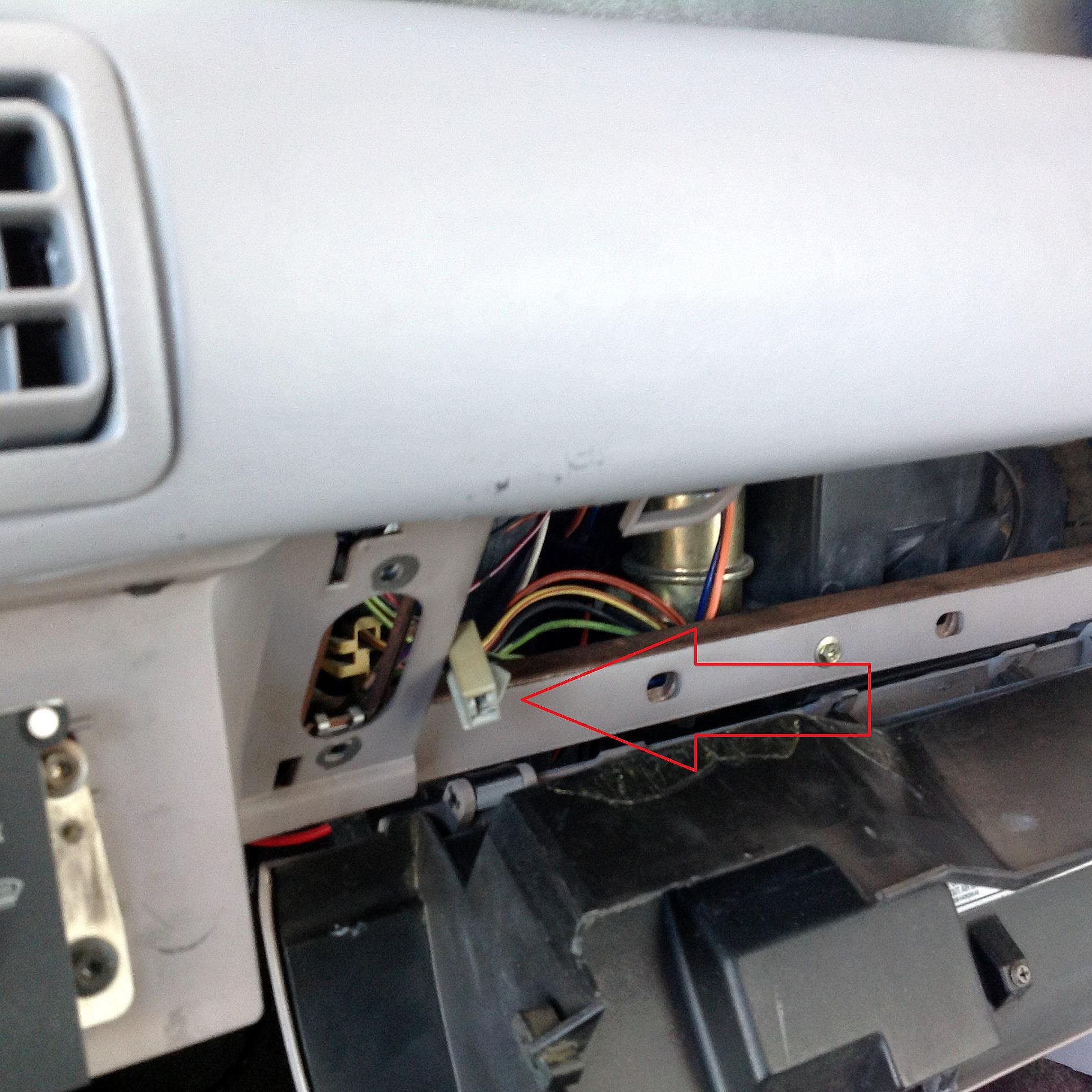

Next, remove the under dash cover by loosening two bolts (one on each side), and gently pulling the cover out of its snap in position.

Continued next post...

I figured since the roof had insulation that I'd check out the floor and see how it was doing.

Remove those pesky seats as you will be ripping up carpet today!

Next, remove the scuff plates. Although, in hind sight, I would remove the plates before the seats as I scraped mine and had to repaint after the job was done...

Remove the arm rest by loosening the 4 bolts (2 each side), then simply pull up on the rest.

For console top plate remove 2 screws at it's rear...

Then 2 screws at it's front.

Before pulling up too hard on the top plate make sure to disconnect any pigtails.

Remove A/C bezel and shifter handle.

Remove 2 torx screws on the right side of the console. Drop the glovebox down for better access by simply pulling the box's release tabs in. Also, don't forget to unplug the trunk pigtail.

Remove the covering that surrounds the steering column by loosening 2 recessed Phillip's head screws. This will allow access to the left side center console torx screws.

Next, remove the under dash cover by loosening two bolts (one on each side), and gently pulling the cover out of its snap in position.

Continued next post...

Update: Floored, Cool, and Silent -Con't

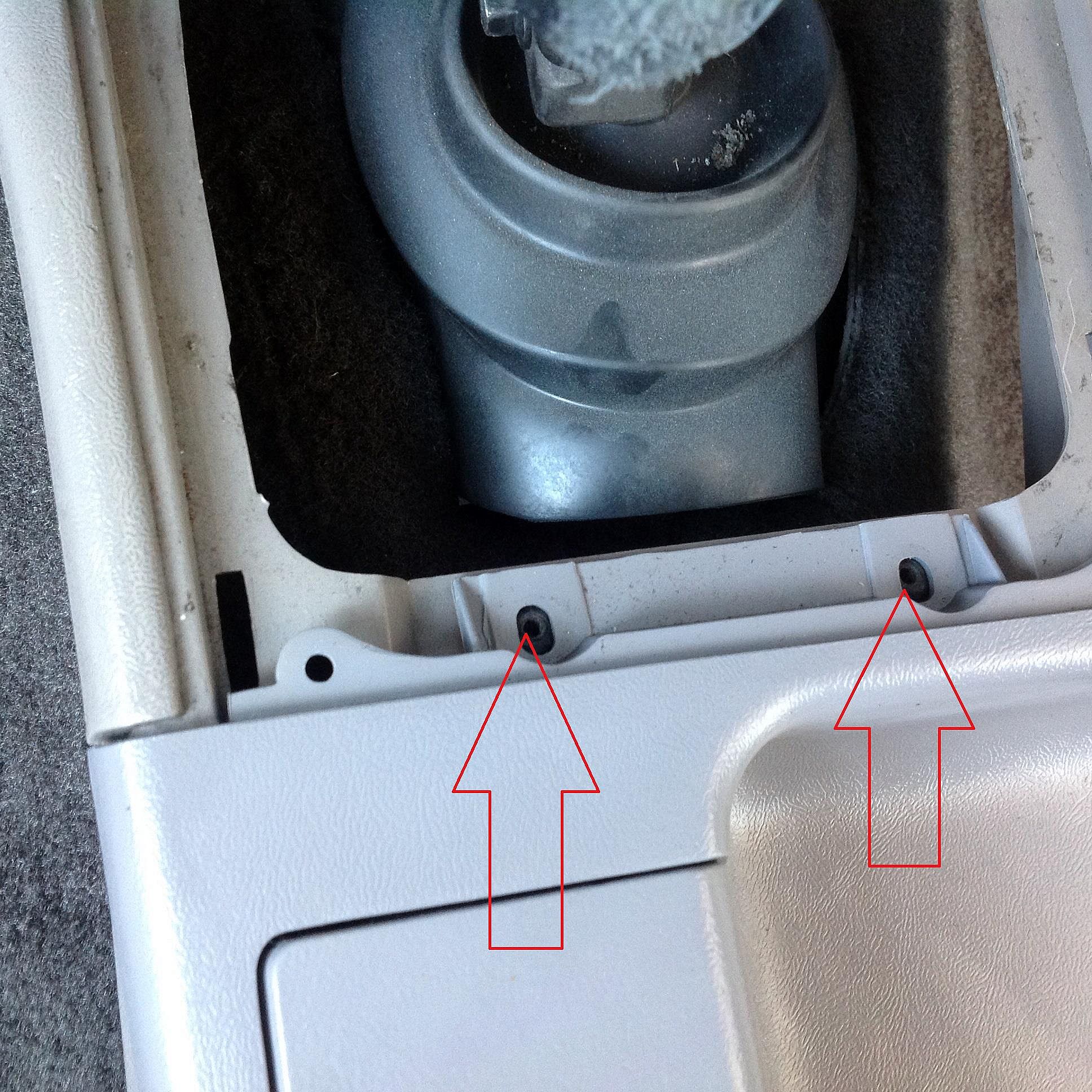

Remove the two torx bolts on the left side center console.

Remove the 3 (or 2) bolts at the rear of the center console you forgot!

You may not GENTLY remove the center console. It helps to have the shifter in reverse for clearance sake.

Next, cry over the scratch you put in your newly painted dash pad because you didn't remove the center console GENTLY!

Remove seat belts...

Remove both kick panels...

Remove the back seat by pulling up & out...

Loosen the screws on the lower rear trim (both sides) and pull away just enough to manipulate for carpet removal.

Pull out carpet. Pay attention to how it is in the car so you can put it back the same way. Vacuum the entire inside of the floorpan and clean all metal surfaces with alcohol. Also, take this time to inspect wiring and fix if needed. I had several instances where the wire bundles pulled away from the looms. All of that drama got affixed back to the factory location.

At this point you will need to decided if you want to remove the factory insulation or fill in the gaps where Ford didn't. I chose the later. I didn't want to make more work for myself and their black insulation was still strongly affixed.

Continued next post...

Remove the two torx bolts on the left side center console.

Remove the 3 (or 2) bolts at the rear of the center console you forgot!

You may not GENTLY remove the center console. It helps to have the shifter in reverse for clearance sake.

Next, cry over the scratch you put in your newly painted dash pad because you didn't remove the center console GENTLY!

Remove seat belts...

Remove both kick panels...

Remove the back seat by pulling up & out...

Loosen the screws on the lower rear trim (both sides) and pull away just enough to manipulate for carpet removal.

Pull out carpet. Pay attention to how it is in the car so you can put it back the same way. Vacuum the entire inside of the floorpan and clean all metal surfaces with alcohol. Also, take this time to inspect wiring and fix if needed. I had several instances where the wire bundles pulled away from the looms. All of that drama got affixed back to the factory location.

At this point you will need to decided if you want to remove the factory insulation or fill in the gaps where Ford didn't. I chose the later. I didn't want to make more work for myself and their black insulation was still strongly affixed.

Continued next post...

Update: Floored, Cool, and Silent -Con't Again.

Never know what you are going to fine when the carpet is removed. Notice that you can see the asphalt through the floor pan. This is unacceptable if you want any kind of quiet and/or climate control.

This car was an automatic and was converted some time before I got it. Someone just cut a hole and kept going!

Holes covered! Again, I just filled in the spaces Ford did not. Also, I filled in the ridiculous hole all the way around the shifter. I thought it always felt hot around there.

And, put back together. Let me not give the wrong idea. The pics make it seem like a 1-2-3 job, and while its not really technical it does take several hours if you are paying attention to detail.

Hopefully this will help someone else do the same job!

Never know what you are going to fine when the carpet is removed. Notice that you can see the asphalt through the floor pan. This is unacceptable if you want any kind of quiet and/or climate control.

This car was an automatic and was converted some time before I got it. Someone just cut a hole and kept going!

Holes covered! Again, I just filled in the spaces Ford did not. Also, I filled in the ridiculous hole all the way around the shifter. I thought it always felt hot around there.

And, put back together. Let me not give the wrong idea. The pics make it seem like a 1-2-3 job, and while its not really technical it does take several hours if you are paying attention to detail.

Hopefully this will help someone else do the same job!

I haven't driven it since I did the flooring. I only drove it after the roof insulation and that made a difference. I'm assuming the floor will make even more of a difference, especially after closing that huge hole around the shifter.Can you tell a difference now in road noise?

I still have plenty Roadkill left over so I am contemplating on doing the trunk area. If I use the entire box I think it will only add about 40-50 pounds to the car. I was at 2890 lbs to begin with so it should still be fine. Plus, if it bothered me I could just bump the timing 1*, or put an electric fan on to make up the difference.

Two questions:

1) Wasn't it you who turned me onto the Roadkill?

2) In the trunk I already have the factory "sound deadener" piece that goes between the top carpet and spare tire cardboard cover. If I do the Roadkill in the trunk area will I even need that factory piece?

1) I think so, it's what I used in my carI haven't driven it since I did the flooring. I only drove it after the roof insulation and that made a difference. I'm assuming the floor will make even more of a difference, especially after closing that huge hole around the shifter.

I still have plenty Roadkill left over so I am contemplating on doing the trunk area. If I use the entire box I think it will only add about 40-50 pounds to the car. I was at 2890 lbs to begin with so it should still be fine. Plus, if it bothered me I could just bump the timing 1*, or put an electric fan on to make up the difference.

Two questions:

1) Wasn't it you who turned me onto the Roadkill?

2) In the trunk I already have the factory "sound deadener" piece that goes between the top carpet and spare tire cardboard cover. If I do the Roadkill in the trunk area will I even need that factory piece?

2) Too much is never enough. I've had the rattle trap drag car in the past and now I am in the mood for quiet and plush. If the weight doesn't bother you, I'd use everything I can. I plan on doing more when funds allow.

1) Thank you! That stuff is great.1) I think so, it's what I used in my car

2) Too much is never enough. I've had the rattle trap drag car in the past and now I am in the mood for quiet and plush. If the weight doesn't bother you, I'd use everything I can. I plan on doing more when funds allow.

2) Okay, sounds good. I hear you. In my 20s I ripped out everything I could to be faster. In my 40s I'm putting stuff in to be quiet and cooler. Things sure change.

Similar threads

Progress Thread

H/C Swap Problems/Ideas

- Replies

- 3

- Views

- 405

- Replies

- 19

- Views

- 2K

- Replies

- 6

- Views

- 1K

- Replies

- 92

- Views

- 7K