I ordered my radiator last week (finally – I’ve been waiting to upgrade to an aluminum unit since I got my Vintage Air system 2 years ago). Saturday I went hunting for a Taurus fan at the salvage yards and picked one up for $75.

My radiator came in yesterday (Summit 380425 - $169) and the first thing I did was check the fit of the fan shroud.

It couldn’t have been much better:

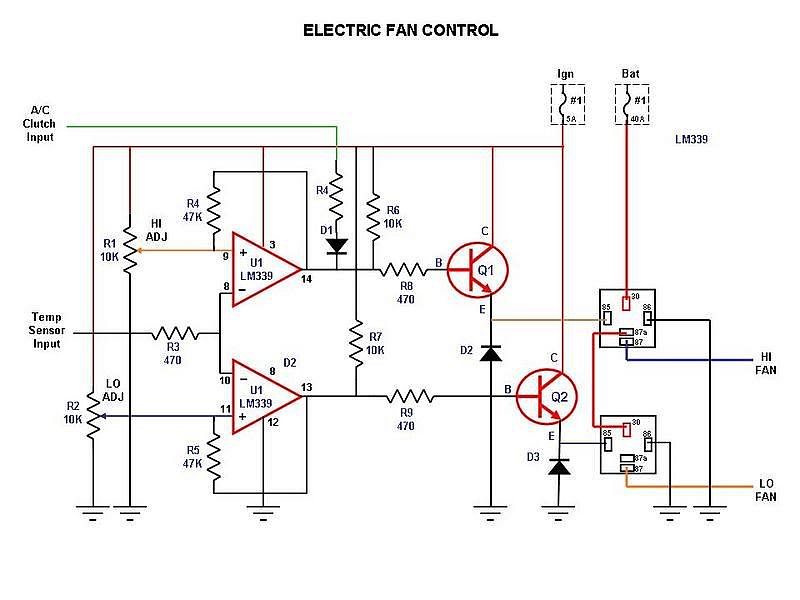

I’m working on putting together the fan control unit with low $ parts. I’ll keep y’all updated.

My radiator came in yesterday (Summit 380425 - $169) and the first thing I did was check the fit of the fan shroud.

It couldn’t have been much better:

I’m working on putting together the fan control unit with low $ parts. I’ll keep y’all updated.

I think I'm just going to get a '70's type WP and take on the other mods later.

I think I'm just going to get a '70's type WP and take on the other mods later.

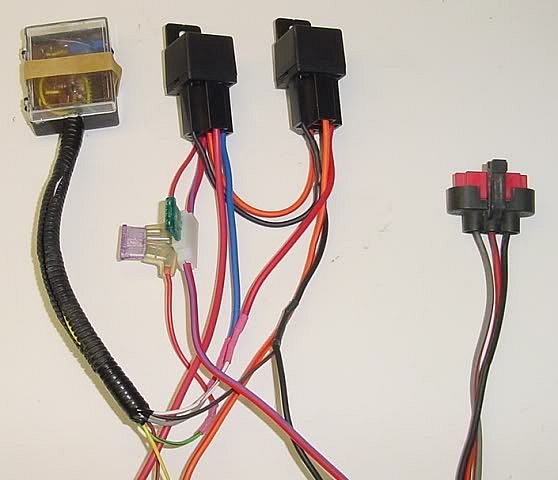

Not one of my better moments. Looked right at the relays (even noticed how you wired them so that the "high speed" relay opens its N/C contact to kill power to the "low speed" relay) - then I promptly forgot they were in the circuit. Can I claim that I was tired?

Not one of my better moments. Looked right at the relays (even noticed how you wired them so that the "high speed" relay opens its N/C contact to kill power to the "low speed" relay) - then I promptly forgot they were in the circuit. Can I claim that I was tired?