femurphy77

Member

- Nov 9, 2011

- 14

- 6

- 13

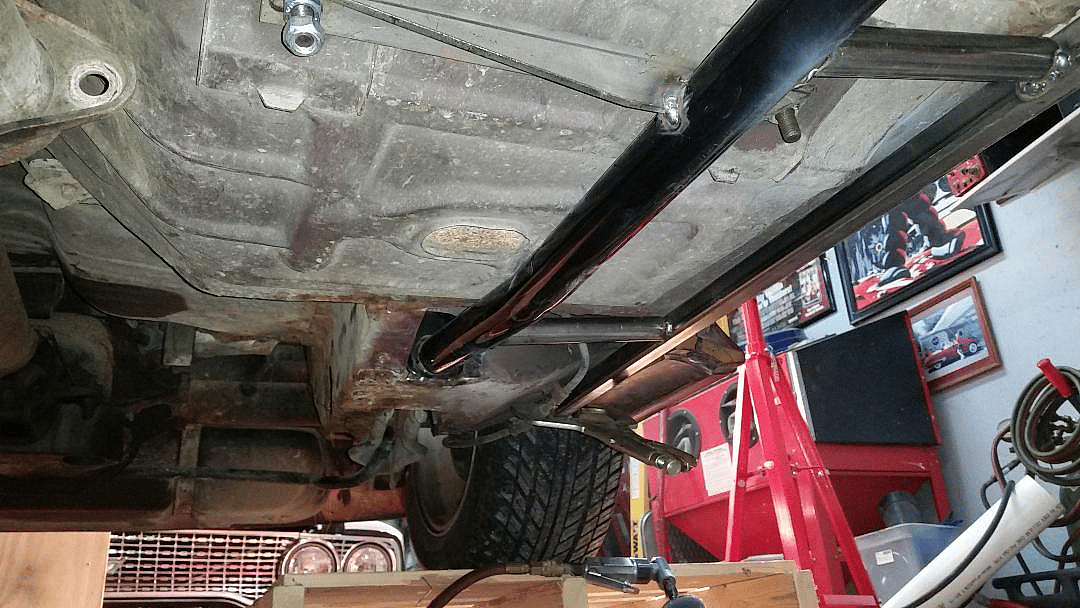

Just as a follow up to everything above I took my 89 Vert out for the first time today since installing them and I'm happy to report that again the result of adding SFC's to a Fox is WOW! I wondered how much of a difference it would make on a vert and it appears to be quite substantial. Cowl shake appears to have been eliminated, the ride feels firmer, throttle induced oversteer seems to come on quite a lot easier than before. All in all the effort has been worth it.

Not a very detailed photo of the SFC's but if you look close you can see them in there. The exhaust turndowns are temporary, I had planned on getting my IRS installed this winter as well but some needed parts were backordered for over a month. Since warm weather is rapidly approaching I decided to delay the install yet again.

The turndowns do alter the sound of those flowmasters though, it really brings out that flowmaster bass that I do love so. I may just end up leaving them even after the IRS install is complete.

Not a very detailed photo of the SFC's but if you look close you can see them in there. The exhaust turndowns are temporary, I had planned on getting my IRS installed this winter as well but some needed parts were backordered for over a month. Since warm weather is rapidly approaching I decided to delay the install yet again.

The turndowns do alter the sound of those flowmasters though, it really brings out that flowmaster bass that I do love so. I may just end up leaving them even after the IRS install is complete.

Last edited: