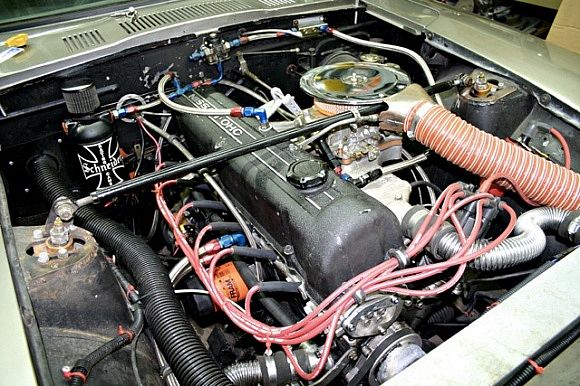

I started another thread to try and get opinions that would not otherwise get offered on my daily beast here.

Seems a few folks believe that I'll suffer from reversion,..and fuel standoff back spray out into the air plenum/filter/atmosphere with this system.And that low speed port velocity will be non-existent due to the total surface area that opens, and closes at the same time...

I'm betting against that...The engine that these TB's came off of did not suffer from any of the drivability concerns.

It makes sense to me That: The commensurate amount of fuel required to cover the air gap is gonna happen as a result of throttle percentage when/if I convert to Alpha N, and that's gonna be totally dependent on whether or not the speed density system goes to hell when I build this vacuum reservoir/ remote plenum that all six tb's will be plumbed into.

when the throttle blade cracks open, it's only gonna take a fraction of the pedal travel to create the same amount of throttle opening that would've had to happen with the old single TB...the issue may be that the engine would be too slow to respond RPM wise to a quick snap open of the throttle, and that would result in a bog..

I've never seen a BMW M three bog.

Seems a few folks believe that I'll suffer from reversion,..and fuel standoff back spray out into the air plenum/filter/atmosphere with this system.And that low speed port velocity will be non-existent due to the total surface area that opens, and closes at the same time...

I'm betting against that...The engine that these TB's came off of did not suffer from any of the drivability concerns.

It makes sense to me That: The commensurate amount of fuel required to cover the air gap is gonna happen as a result of throttle percentage when/if I convert to Alpha N, and that's gonna be totally dependent on whether or not the speed density system goes to hell when I build this vacuum reservoir/ remote plenum that all six tb's will be plumbed into.

when the throttle blade cracks open, it's only gonna take a fraction of the pedal travel to create the same amount of throttle opening that would've had to happen with the old single TB...the issue may be that the engine would be too slow to respond RPM wise to a quick snap open of the throttle, and that would result in a bog..

I've never seen a BMW M three bog.