Best to take it apart and do it correctly this time...

Q.: Clutch/Transmission Installation Tips For 1986 and Newer V-8 Mustangs

A.: The flywheel to crankshaft bolts must be hand-torqued to 75-85 ft./lbs. (302/351W) and 54-64 ft./lbs. (4.6L) The 10.5" pressure plate bolts must be torqued to 12-24 ft./lbs. and 11" pressure plate bolts to 33 ft./lbs. + 1/4 turn.

Be sure to use the alignment dowels in the flywheels. Pressure plate bolts and alignment dowels for the 10.5" clutch can be purchased using PN M-6397-A302. Pressure plate bolts N808969-S100 and alignment dowels D1FZ-6397-B are for the 11" pressure plate.

Evenly tighten bolts in a circular direction one turn at a time. Bellhousing alignment is crucial for proper clutch and transmission function.

Due to production tolerances of engine blocks and bellhousings, it is possible for the transmission centerline and crankshaft centerline to be misaligned. Misalignment can cause transmission gear wear, transmission jumping out of gear, driveline vibration, clutch pedal vibration, pilot bearing noise, release bearing noise or excessive clutch spin time. It may also damage the pilot bearing, transmission mainshaft bearing and clutch hub. It will also cause harsh shifting.

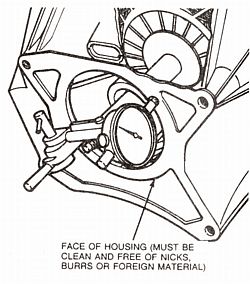

Before installing the bellhousing, check the block mounting surface and bellhousing surfaces for nicks, dents, paint debris, etc. These are some things that could affect the accuracy of your measurements.

Q.: How do I check bellhousing alignment?

A.: The first step is to check bellhousing face runout. You are checking for parallelism of the back of the bellhousing to the back of the block. Install the dial indicator (as shown fig.1). Rotate the crankshaft and mark down the reading. Be sure to push the crankshaft against the thrust bearing for an accurate reading. Maximum runout is .010.

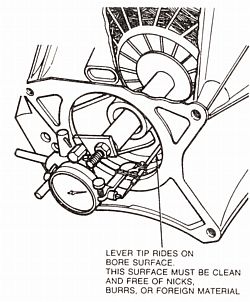

The next step is checking bellhousing bore runout. You are checking to see if the bellhousing bore centerline is aligned with crankshaft centerline. Reposition the dial indicator in the bellhousing bore (as shown fig. 2). Rotate the crankshaft and mark down the readings. Maximum out of concentricity is .015. If the bore runout is out of spec. install appropriate offset dowels.

Offset alignment dowels can be purchased from Lakewood.

.007 PN 15950

.014 PN 15960

.021 PN 15970

I didnt install any dowells on the new flywheel My question is would that make a differance on my chatter problem or will the chatter go away after break in like the last clutch I did.

I didnt install any dowells on the new flywheel My question is would that make a differance on my chatter problem or will the chatter go away after break in like the last clutch I did.

. DO you feel any vibration or anything when setting in neutral or with the clutch in?

. DO you feel any vibration or anything when setting in neutral or with the clutch in?