Damn, that was my dumb move of the day.  I didn't even think about the spout connector.

I didn't even think about the spout connector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread My First Notch Build Thread - Remember me?!

- Thread starter stangboy

- Start date

-

Sponsors (?)

No Crank checklist for 5.0 Mustangs

Revised 24-Oct-2013 to update voltage drop figures.

No crank, slow crank and stuck starter solenoid problems have the same root causes – low battery voltage and poor connections. For that reason, they are grouped together.

Use the same initial group of tests to find the root cause of slow crank, no crank and stuck solenoid problems.

Since some of the tests will bypass the safety interlocks, make sure that the car is in neutral and the parking brake is set. Becoming a pancake isn’t part of the repair process…

1.) Will the car start if it is jumped? Then clean battery terminals and check battery for low charge and dead cells. A good battery will measure 12-13 volts at full charge with the ignition switch in the Run position but without the engine running.

A voltmeter placed across the battery terminals should show a minimum of 9.5-10 volts when the ignition switch is turned to the Start position and the starter engages or tries to engage. Less than this will result in a clicking solenoid, or slow cranking (if it cranks at all) or a starter solenoid that sticks and welds the contacts together.

Most auto parts stores will check your battery for free. It does not have to be installed in the car to have it checked; you can carry it with you to the auto parts store.

The battery posts and inside of the battery post terminals should be scraped clean with a knife or battery post cleaner tool. This little trick will fix a surprising number of no start problems.

The clamp on with 2 bolts battery terminal ends are a known problem causer. Any place you see green on a copper wire is corrosion. Corrosion gets in the clamped joint and works its way up the wire under the insulation. Corroded connections do not conduct electricity well. Avoid them like the plague...

If the starter solenoid welds the contacts, then the starter will attempt to run anytime there is power in the battery. The cables and solenoid will get very hot, and may even start smoking. The temporary fix for a welded starter solenoid is to disconnect the battery and smack the back of the solenoid housing a sharp blow with a hammer. This may cause the contacts to unstick and work normally for a while.

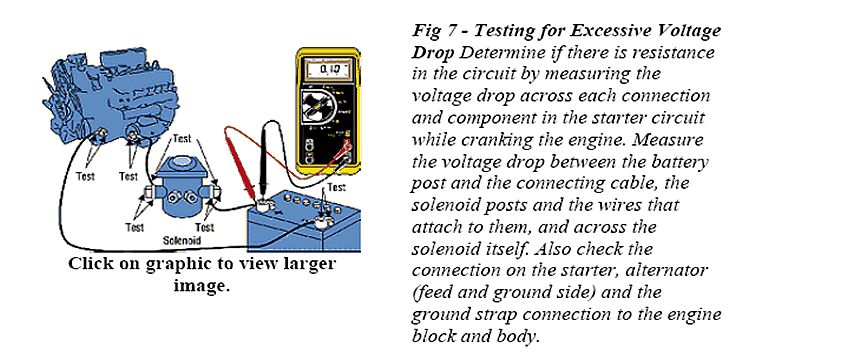

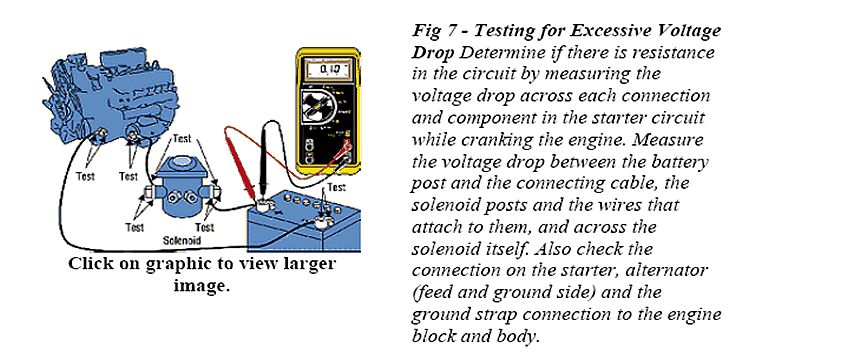

A voltmeter is handy if you are familiar with how to use it to find bad connections. Measure the voltage drop across a connection while trying to start the car: more than .25 volts across a connection indicates a problem. The voltage drop tests need to be done while cranking the engine. It's the current flowing through a connection or wire that causes the voltage drop.

See http://assets.fluke.com/appnotes/automotive/beatbook.pdf for help for help troubleshooting voltage drops across connections and components. .

Voltage drops should not exceed the following:

200 mV Wire or cable

300 mV Switch or solenoid

100 mV Ground

0.0V Connections

A voltage drop lower that spec is always acceptable.

2.) Check the battery to engine block ground down near the oil filter, and the ground behind the engine to the firewall. All grounds should be clean and shiny. Use some sandpaper to clean them up.

3.) Jump the big terminals on the starter solenoid next to the battery with a screwdriver - watch out for the sparks! If the engine cranks, the starter and power wiring is good. The starter relay is also known as a starter solenoid.

The rest of the tech note only concerns no crank problems. If your problem was a stuck solenoid, go back to step 1.

4.) Then pull the small push on connector (small red/blue wire) off the starter solenoid (Looks like it is stuck on a screw). Then jump between the screw and the terminal that is connected to the battery. If it cranks, the relay is good and your problem is in the rest of the circuit.

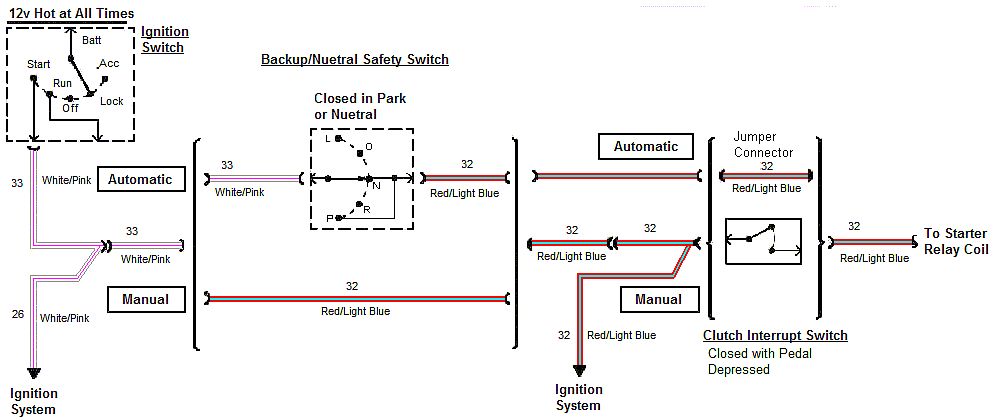

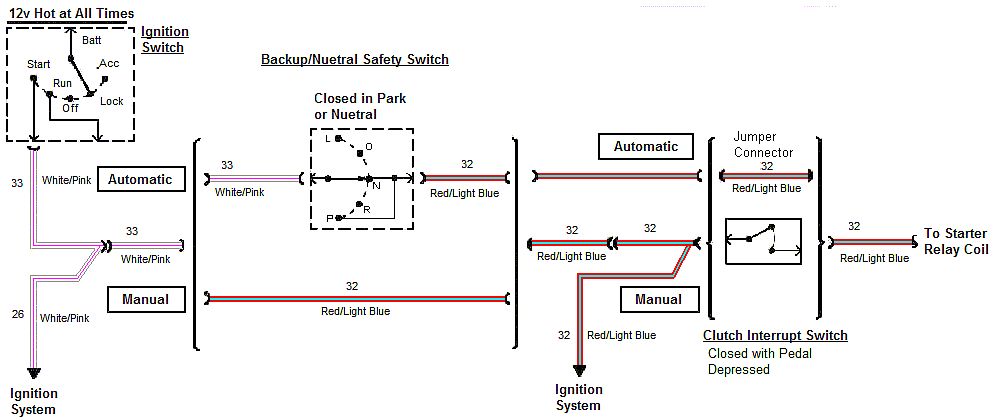

5.) Remember to check the ignition switch, neutral safety switch on auto trans and the clutch safety switch on manual trans cars. If they are good, then you have wiring problems.

Typical start circuit...

Diagram courtesy of Tmoss & Stang&2birds

6.) Pull the starter and take it to AutoZone or Pep Boys and have them test it. Starter fails test, then replace it. If you got this far, the starter is probably bad.

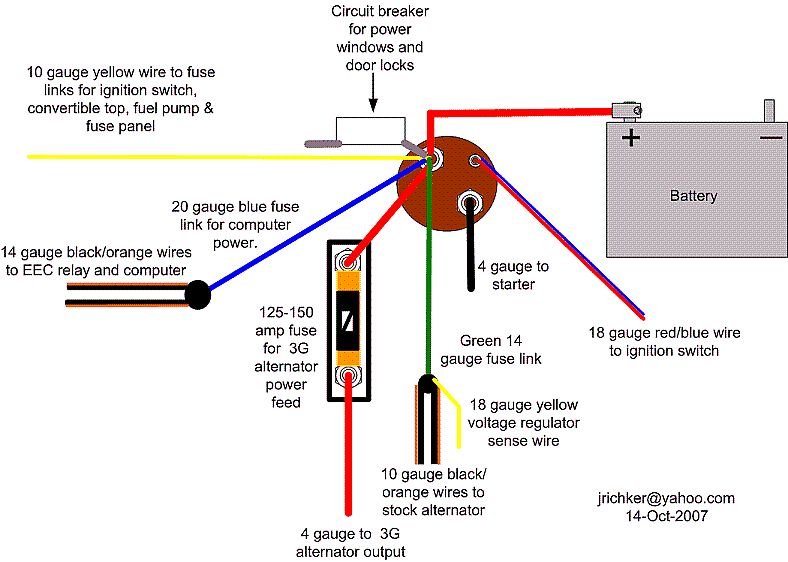

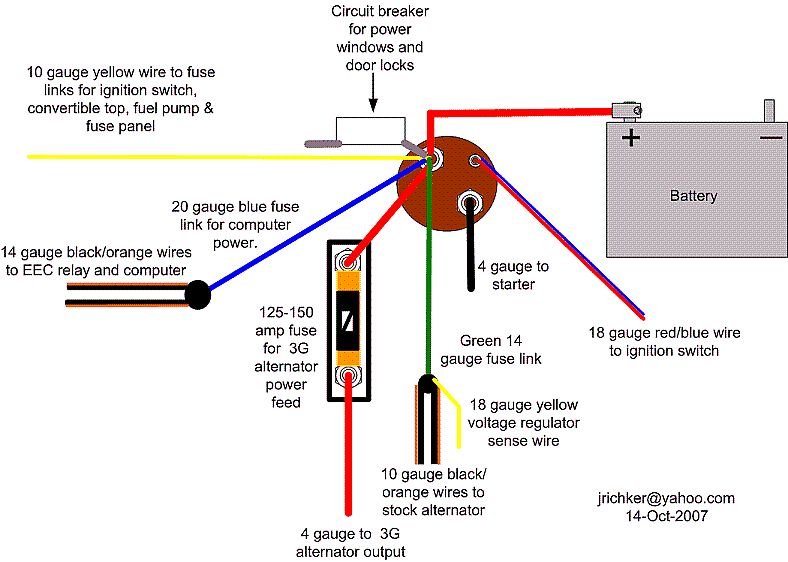

Starter solenoid wiring for 86-91 Mustang

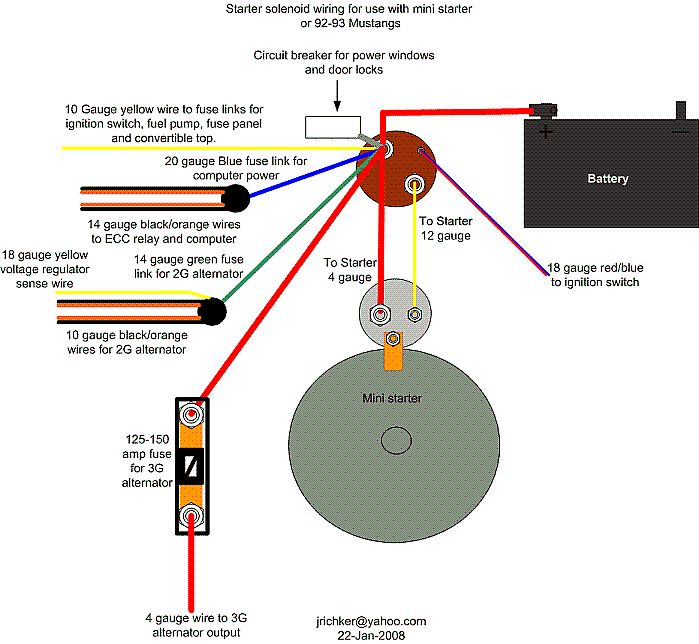

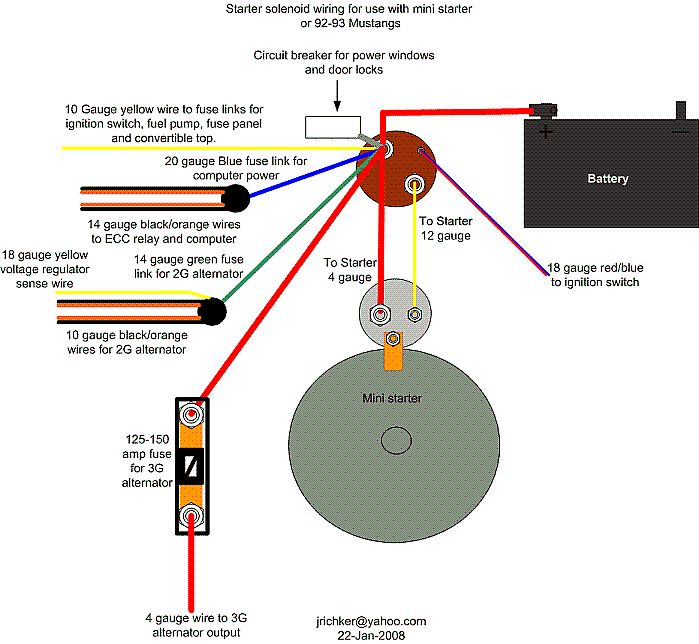

Starter solenoid wiring 92-93 Mustang or earlier Mustang with upgraded high torque mini starter.

Electrical checks for the switches and starter solenoid

Remove the small red/blue wire from the starter solenoid. Use a screwdriver to bridge the connection from the battery positive connection on the starter solenoid to the small screw where the red/blue wire was connected. The starter should crank the engine. If it does not, the starter solenoid is defective or the battery lacks sufficient charge to crank the engine.

If the starter does crank the engine, the problem is in the clutch safety circuit (5 speed) or Neutral Sense Switch (auto trans) or ignition switch.

See the Typical start circuit diagram above for wiring information for troubleshooting.

You will need a voltmeter or test lamp for the rest of the checks. Connect one lead of the voltmeter or test lamp to ground. The other lead will connect to the item under test.

Look for 12 volts on the white/pink wire when the ignition switch is turned to the Start position. Check the ignition switch first.

No 12 volts, replace the ignition switch.

The next step will require you to push the clutch pedal to the floor (5 speed) or put the transmission in neutral (auto trans) while the ignition switch is turned to the Start position.

Good 12 volts, check the clutch safety switch (5 speed) or Neutral Sense Switch (auto trans) for good 12 volts on both sides of the switches. No 12 volts on both sides of the switch and the switches are defective or out of adjustment. Check the wiring for bad connections while you are at it.

Fuel Pump Troubleshooting for 87-90 Mustangs

Revised 1-Dec-2015 to add fuse links diagram.

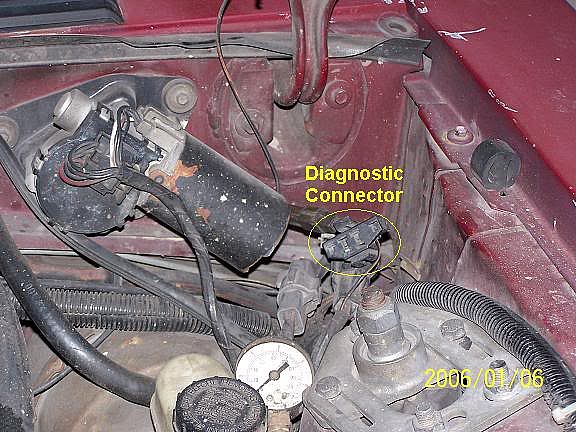

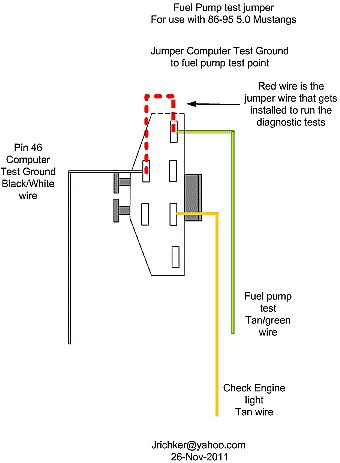

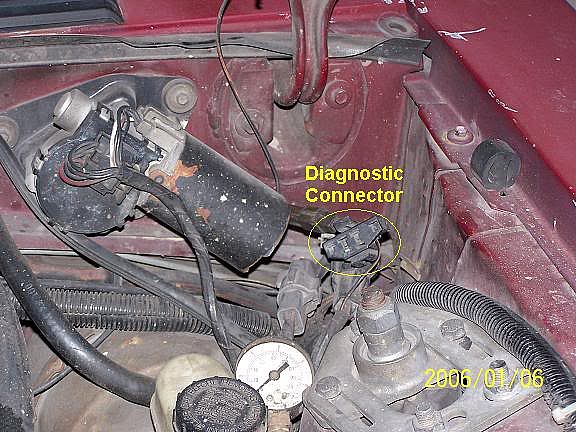

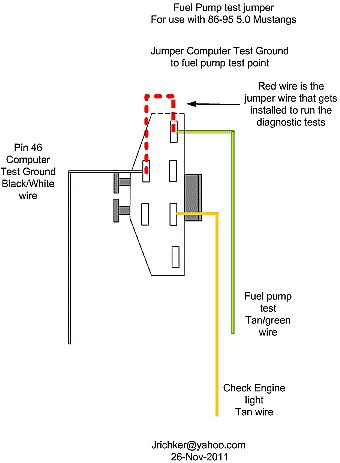

Clue – listen for the fuel pump to prime when you first turn the ignition switch on. It should run for 1-3 seconds and shut off. To trick the fuel pump into running, find the ECC test connector and jump the connector in the upper LH corner to ground.

Turn the ignition switch on when you do this test.

If the fuse links are OK, you will have power to the pump. Check fuel pressure – remove the cap from the Schrader valve behind the alternator and depress the core. Fuel should squirt out, catch it in a rag. A tire pressure gauge can also be used if you have one - look for 37-40 PSI. Beware of fire hazard when you do this.

No fuel pressure, possible failed items in order of their probability:

A.) Tripped inertia switch – press reset button on the inertia switch. The hatch cars hide it under the plastic trim covering the driver's side taillight. Use the voltmeter or test light to make sure you have power to both sides of the switch

B.) Fuel pump power relay – located under the driver’s seat in most Mustangs built before 92. See the diagram to help identify the fuel pump relay wiring colors. Be sure to closely check the condition of the relay, wiring & socket for corrosion and damage.

C.) Clogged fuel filter

D.) Failed fuel pump

E.) Blown fuse link in wiring harness.

F.) Fuel pressure regulator failed. Remove vacuum line from regulator and inspect

for fuel escaping while pump is running.

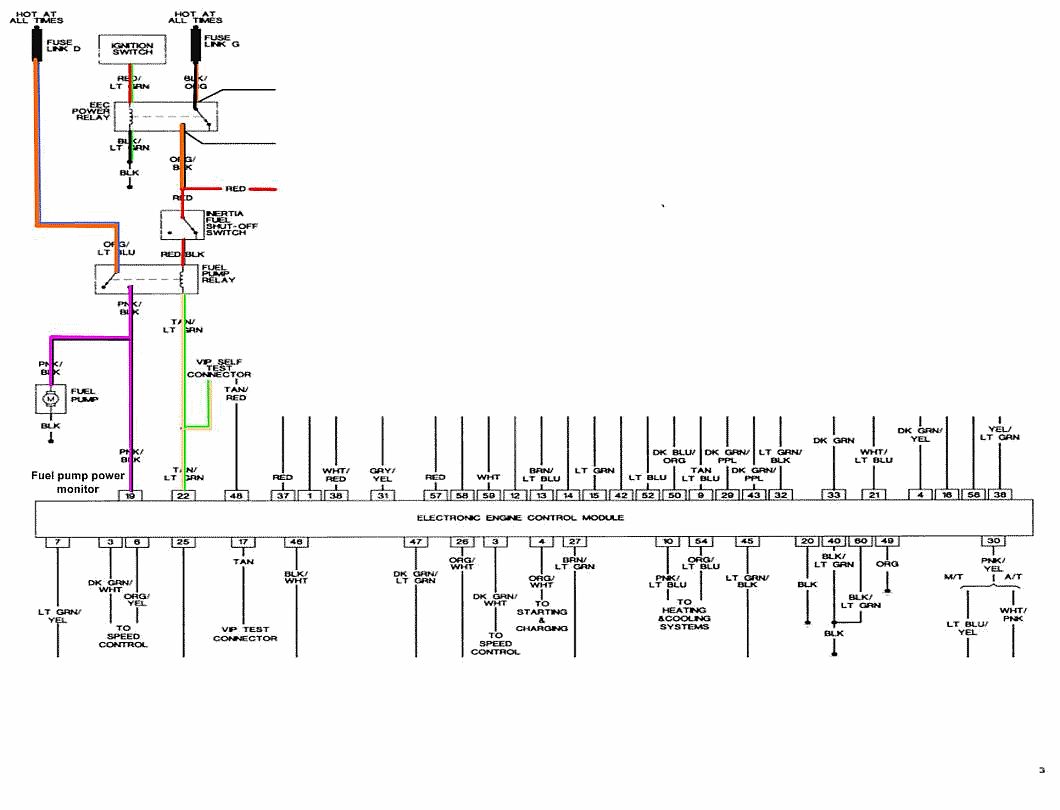

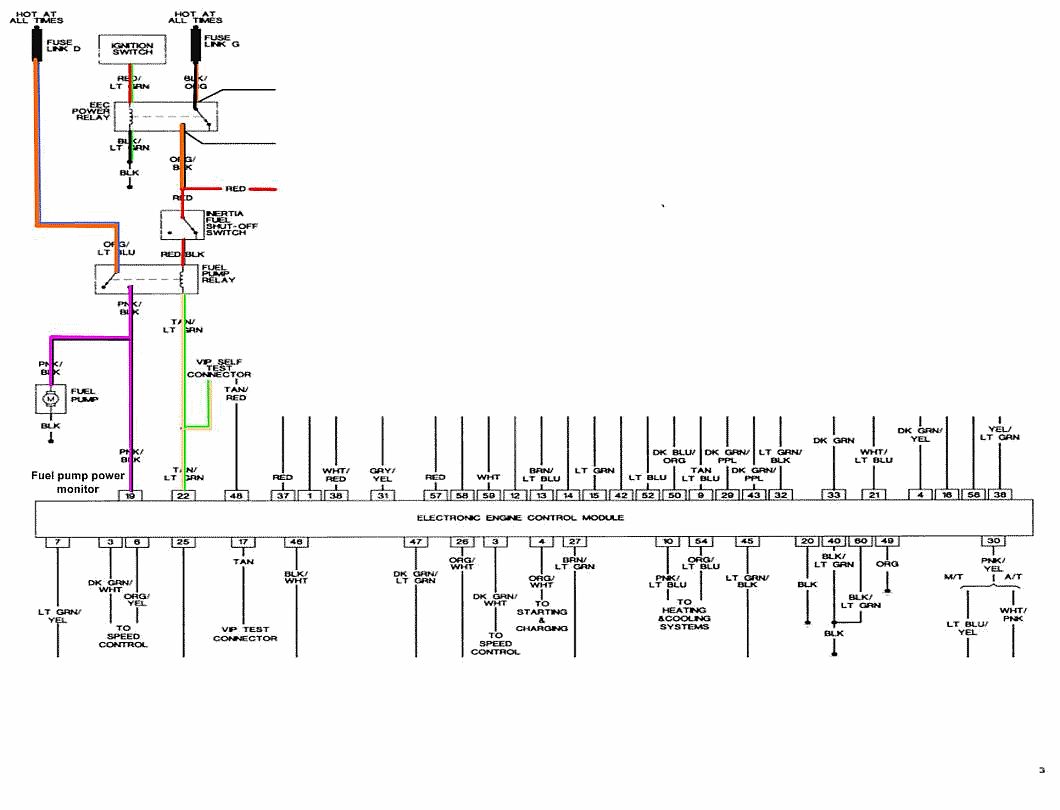

The electrical circuit for the fuel pump has two paths, a control path and a power

path.

Control Path

The control path consists of the inertia switch, the computer, and the fuel pump relay coil. It turns the fuel pump relay on or off under computer control. The switched power (red wire) from the ECC relay goes to the inertia switch (red/black wire) then from the inertia switch to the relay coil and then from the relay coil to the computer (tan/ Lt green wire). The computer provides the ground path to complete the circuit. This ground causes the relay coil to energize and close the contacts for the power path. Keep in mind that you can have voltage to all the right places, but the computer must provide a ground. If there is no ground, the relay will not close the power contacts.

Power Path

The power path picks up from a fuse link near the starter relay. Fuse links are like fuses, except they are pieces of wire and are made right into the wiring harness. The feed wire from the fuse link (orange/ light blue wire) goes to the fuel pump relay contacts.

Fuse links

Fuse links come with a current rating just like fuses. A clue as to what current they are designed for is to look at the size wire they protect. Fuse link material is available at most good auto parts stores. There may even be a fuse link already made up specifically for your car. Just be sure to solder the connection and cover it with heat shrink tubing.

Heat shrink tubing is available at Radio Shack or other electronics supply stores.

See the video below for help on soldering and heat shrinking wiring. There is a lot of useful help and hints if you don’t do automotive electrical work all the time.

View: http://youtu.be/uaYdCRjDr4A

When the contacts close because the relay energizes, the power flows through the contacts to the fuel pump (light pink/black wire). Notice that pin 19 on the computer is the monitor to make sure the pump has power. The fuel pump has a black wire that supplies the ground to complete the circuit.

Remember that the computer does not source any power to actuators, relays or injectors, but provides the ground necessary to complete the circuit. That means one side of the circuit will always be hot, and the other side will go to ground or below 1 volt as the computer switches on that circuit.

Now that you have the theory of how it works, it’s time to go digging.

All voltage reading are made with one voltmeter lead connected to the metal car body unless otherwise specified

Check for 12 volts at the red wire on the inertia switch. No 12 volts at the inertia switch, the ignition switch is turned off or faulty or there is no power to the EEC (computer) power relay. To be sure look for good 12 volts on the red wire on any fuel injector.

Good 12 volts means the EEC relay is working. No 12 volts and the ECC wiring is at fault.

Look for 12 volts on the red/green wire on the ignition coil: no 12 volts and the ignition switch is faulty, or the fuse link in the ignition power wire has blown. No 12 volts here and the ECC relay won’t close and provide power to the inertia switch. Check the Red/black wire on the inertia switch, it should have 12 volts. No 12 volts there, either the inertia switch is open or has no power to it. Check both sides of the inertia switch: there should be power on the Red wire and Red/Black wire. Power on the Red wire and not on the Red/Black wire means the inertia switch is open. Push the button on the side of it to reset it, and then recheck. Good 12 volts on one side and not on the other means the inertia switch has failed.

Look for 12 volts at the Orange/Lt. Blue wire (power source for fuel pump relay). No voltage or low voltage, bad fuse link, bad wiring, bad ignition switch or ignition switch wiring or connections. There is a mystery connector somewhere under the driver’s side kick panel, between the fuel pump relay and the fuse link.

Turn on the key and jumper the fuel pump test connector to ground as previously described. Look for 12 volts at the Light Pink/Black wire (relay controlled power for the fuel pump). No voltage there means that the relay has failed, or there is a broken wire in the relay control circuit.

Pump wiring: Anytime the ignition switch is in the Run position and the test point is jumpered to ground, there should be at least 12 volts present on the black/pink wire. With power off, check the pump ground: you should see less than 1 ohm between the black wire and chassis ground.

The yellow wire is the fuel tank sender to the fuel quantity gage. The two black wires are grounds. One ground is for the fuel tank sender and the other is the fuel pump. The ground for the fuel pump may be larger gauge wire that the fuel tank sender ground wire.

Make sure that the power is off the circuit before making any resistance checks. If the circuit is powered up, your resistance measurements will be inaccurate.

You should see less than 1 Ohm between the black wire(s) and ground. To get some idea of what a good reading is, short the two meter leads together and observe the reading. It should only be slightly higher when you measure the black wire to ground resistance.

The Tan/Lt Green wire provides a ground path for the relay power. With the test connector jumpered to ground, there should be less than .75 volts. Use a test lamp with one side connected to battery power and the other side to the Tan/Lt Green wire. The test light should glow brightly. No glow and you have a broken wire or bad connection between the test connector and the relay. To test the wiring from the computer, remove the passenger side kick panel and disconnect the computer connector. It has a 10 MM bolt that holds it in place. With the test lamp connected to power, jumper pin 22 to ground and the test lamp should glow. No glow and the wiring between the computer and the fuel pump relay is bad.

Computer: If you got this far and everything else checked out good, the computer is suspect. Remove the test jumper from the ECC test connector located under the hood. Probe computer pin 22 with a safety pin and ground it to chassis. Make sure the computer and everything else is connected. Turn the ignition switch to the Run position and observe the fuel pressure. The pump should run at full pressure.

If it doesn't, the wiring between pin 22 on the computer and the fuel pump relay is bad.

If it does run at full pressure, the computer may have failed.

Keep in mind that the computer only runs the fuel pump for about 2-3 seconds when you turn the key to the Run position. This can sometimes fool you into thinking the computer has died. Connect one lead of the test light to power and the other lead to computer pin 22 with a safety pin. With the ignition switch Off, jumper the computer into self test mode like you are going to dump the codes. Turn the ignition switch to the Run position. The light will flicker when the computer does the self test routine. A flickering light is a good computer. No flickering light is a bad computer.

Remove the test jumper from the ECC test connector located under the hood.

Fuel pump runs continuously: The fuel pump relay contacts are stuck together or the Tan/Lt Green wire has shorted to ground. In extreme ghetto cases, the pump relay may have been bypassed. Remove the fuel pump relay from its socket. Then disconnect the computer and use an ohmmeter to check out the resistance between the Tan/Lt Green wire and ground. You should see more than 10 K Ohms (10,000 ohms) or an infinite open circuit. Be sure that the test connector isn’t jumpered to ground.

If the wiring checks out good, then the computer is the likely culprit.

Prior to replacing the computer, check the computer power ground. The computer has its own dedicated power ground that comes off the ground pigtail on the battery ground wire. Due to it's proximity to the battery, it may become corroded by acid fumes from the battery. It is a black cylinder about 2 1/2" long by 1" diameter with a black/lt green wire. You'll find it up next to the starter solenoid where the wire goes into the wiring harness

If all of the checks have worked OK to this point, then the computer is bad. The computers are very reliable and not prone to failure unless there has been significant electrical trauma to the car. Things like lightning strikes and putting the battery in backwards or connecting jumper cables backwards are about the only thing that kills the computer.

See the following website for some help from Tmoss (diagram designer) &

Stang&2Birds (website host)

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

http://www.veryuseful.com/mustang/tech/engine/images/88-91eecPinout.gif

Revised 24-Oct-2013 to update voltage drop figures.

No crank, slow crank and stuck starter solenoid problems have the same root causes – low battery voltage and poor connections. For that reason, they are grouped together.

Use the same initial group of tests to find the root cause of slow crank, no crank and stuck solenoid problems.

Since some of the tests will bypass the safety interlocks, make sure that the car is in neutral and the parking brake is set. Becoming a pancake isn’t part of the repair process…

1.) Will the car start if it is jumped? Then clean battery terminals and check battery for low charge and dead cells. A good battery will measure 12-13 volts at full charge with the ignition switch in the Run position but without the engine running.

A voltmeter placed across the battery terminals should show a minimum of 9.5-10 volts when the ignition switch is turned to the Start position and the starter engages or tries to engage. Less than this will result in a clicking solenoid, or slow cranking (if it cranks at all) or a starter solenoid that sticks and welds the contacts together.

Most auto parts stores will check your battery for free. It does not have to be installed in the car to have it checked; you can carry it with you to the auto parts store.

The battery posts and inside of the battery post terminals should be scraped clean with a knife or battery post cleaner tool. This little trick will fix a surprising number of no start problems.

The clamp on with 2 bolts battery terminal ends are a known problem causer. Any place you see green on a copper wire is corrosion. Corrosion gets in the clamped joint and works its way up the wire under the insulation. Corroded connections do not conduct electricity well. Avoid them like the plague...

If the starter solenoid welds the contacts, then the starter will attempt to run anytime there is power in the battery. The cables and solenoid will get very hot, and may even start smoking. The temporary fix for a welded starter solenoid is to disconnect the battery and smack the back of the solenoid housing a sharp blow with a hammer. This may cause the contacts to unstick and work normally for a while.

A voltmeter is handy if you are familiar with how to use it to find bad connections. Measure the voltage drop across a connection while trying to start the car: more than .25 volts across a connection indicates a problem. The voltage drop tests need to be done while cranking the engine. It's the current flowing through a connection or wire that causes the voltage drop.

See http://assets.fluke.com/appnotes/automotive/beatbook.pdf for help for help troubleshooting voltage drops across connections and components. .

Voltage drops should not exceed the following:

200 mV Wire or cable

300 mV Switch or solenoid

100 mV Ground

0.0V Connections

A voltage drop lower that spec is always acceptable.

2.) Check the battery to engine block ground down near the oil filter, and the ground behind the engine to the firewall. All grounds should be clean and shiny. Use some sandpaper to clean them up.

3.) Jump the big terminals on the starter solenoid next to the battery with a screwdriver - watch out for the sparks! If the engine cranks, the starter and power wiring is good. The starter relay is also known as a starter solenoid.

The rest of the tech note only concerns no crank problems. If your problem was a stuck solenoid, go back to step 1.

4.) Then pull the small push on connector (small red/blue wire) off the starter solenoid (Looks like it is stuck on a screw). Then jump between the screw and the terminal that is connected to the battery. If it cranks, the relay is good and your problem is in the rest of the circuit.

5.) Remember to check the ignition switch, neutral safety switch on auto trans and the clutch safety switch on manual trans cars. If they are good, then you have wiring problems.

Typical start circuit...

Diagram courtesy of Tmoss & Stang&2birds

6.) Pull the starter and take it to AutoZone or Pep Boys and have them test it. Starter fails test, then replace it. If you got this far, the starter is probably bad.

Starter solenoid wiring for 86-91 Mustang

Starter solenoid wiring 92-93 Mustang or earlier Mustang with upgraded high torque mini starter.

Electrical checks for the switches and starter solenoid

Remove the small red/blue wire from the starter solenoid. Use a screwdriver to bridge the connection from the battery positive connection on the starter solenoid to the small screw where the red/blue wire was connected. The starter should crank the engine. If it does not, the starter solenoid is defective or the battery lacks sufficient charge to crank the engine.

If the starter does crank the engine, the problem is in the clutch safety circuit (5 speed) or Neutral Sense Switch (auto trans) or ignition switch.

See the Typical start circuit diagram above for wiring information for troubleshooting.

You will need a voltmeter or test lamp for the rest of the checks. Connect one lead of the voltmeter or test lamp to ground. The other lead will connect to the item under test.

Look for 12 volts on the white/pink wire when the ignition switch is turned to the Start position. Check the ignition switch first.

No 12 volts, replace the ignition switch.

The next step will require you to push the clutch pedal to the floor (5 speed) or put the transmission in neutral (auto trans) while the ignition switch is turned to the Start position.

Good 12 volts, check the clutch safety switch (5 speed) or Neutral Sense Switch (auto trans) for good 12 volts on both sides of the switches. No 12 volts on both sides of the switch and the switches are defective or out of adjustment. Check the wiring for bad connections while you are at it.

Fuel Pump Troubleshooting for 87-90 Mustangs

Revised 1-Dec-2015 to add fuse links diagram.

Clue – listen for the fuel pump to prime when you first turn the ignition switch on. It should run for 1-3 seconds and shut off. To trick the fuel pump into running, find the ECC test connector and jump the connector in the upper LH corner to ground.

Turn the ignition switch on when you do this test.

If the fuse links are OK, you will have power to the pump. Check fuel pressure – remove the cap from the Schrader valve behind the alternator and depress the core. Fuel should squirt out, catch it in a rag. A tire pressure gauge can also be used if you have one - look for 37-40 PSI. Beware of fire hazard when you do this.

No fuel pressure, possible failed items in order of their probability:

A.) Tripped inertia switch – press reset button on the inertia switch. The hatch cars hide it under the plastic trim covering the driver's side taillight. Use the voltmeter or test light to make sure you have power to both sides of the switch

B.) Fuel pump power relay – located under the driver’s seat in most Mustangs built before 92. See the diagram to help identify the fuel pump relay wiring colors. Be sure to closely check the condition of the relay, wiring & socket for corrosion and damage.

C.) Clogged fuel filter

D.) Failed fuel pump

E.) Blown fuse link in wiring harness.

F.) Fuel pressure regulator failed. Remove vacuum line from regulator and inspect

for fuel escaping while pump is running.

The electrical circuit for the fuel pump has two paths, a control path and a power

path.

Control Path

The control path consists of the inertia switch, the computer, and the fuel pump relay coil. It turns the fuel pump relay on or off under computer control. The switched power (red wire) from the ECC relay goes to the inertia switch (red/black wire) then from the inertia switch to the relay coil and then from the relay coil to the computer (tan/ Lt green wire). The computer provides the ground path to complete the circuit. This ground causes the relay coil to energize and close the contacts for the power path. Keep in mind that you can have voltage to all the right places, but the computer must provide a ground. If there is no ground, the relay will not close the power contacts.

Power Path

The power path picks up from a fuse link near the starter relay. Fuse links are like fuses, except they are pieces of wire and are made right into the wiring harness. The feed wire from the fuse link (orange/ light blue wire) goes to the fuel pump relay contacts.

Fuse links

Fuse links come with a current rating just like fuses. A clue as to what current they are designed for is to look at the size wire they protect. Fuse link material is available at most good auto parts stores. There may even be a fuse link already made up specifically for your car. Just be sure to solder the connection and cover it with heat shrink tubing.

Heat shrink tubing is available at Radio Shack or other electronics supply stores.

See the video below for help on soldering and heat shrinking wiring. There is a lot of useful help and hints if you don’t do automotive electrical work all the time.

View: http://youtu.be/uaYdCRjDr4A

When the contacts close because the relay energizes, the power flows through the contacts to the fuel pump (light pink/black wire). Notice that pin 19 on the computer is the monitor to make sure the pump has power. The fuel pump has a black wire that supplies the ground to complete the circuit.

Remember that the computer does not source any power to actuators, relays or injectors, but provides the ground necessary to complete the circuit. That means one side of the circuit will always be hot, and the other side will go to ground or below 1 volt as the computer switches on that circuit.

Now that you have the theory of how it works, it’s time to go digging.

All voltage reading are made with one voltmeter lead connected to the metal car body unless otherwise specified

Check for 12 volts at the red wire on the inertia switch. No 12 volts at the inertia switch, the ignition switch is turned off or faulty or there is no power to the EEC (computer) power relay. To be sure look for good 12 volts on the red wire on any fuel injector.

Good 12 volts means the EEC relay is working. No 12 volts and the ECC wiring is at fault.

Look for 12 volts on the red/green wire on the ignition coil: no 12 volts and the ignition switch is faulty, or the fuse link in the ignition power wire has blown. No 12 volts here and the ECC relay won’t close and provide power to the inertia switch. Check the Red/black wire on the inertia switch, it should have 12 volts. No 12 volts there, either the inertia switch is open or has no power to it. Check both sides of the inertia switch: there should be power on the Red wire and Red/Black wire. Power on the Red wire and not on the Red/Black wire means the inertia switch is open. Push the button on the side of it to reset it, and then recheck. Good 12 volts on one side and not on the other means the inertia switch has failed.

Look for 12 volts at the Orange/Lt. Blue wire (power source for fuel pump relay). No voltage or low voltage, bad fuse link, bad wiring, bad ignition switch or ignition switch wiring or connections. There is a mystery connector somewhere under the driver’s side kick panel, between the fuel pump relay and the fuse link.

Turn on the key and jumper the fuel pump test connector to ground as previously described. Look for 12 volts at the Light Pink/Black wire (relay controlled power for the fuel pump). No voltage there means that the relay has failed, or there is a broken wire in the relay control circuit.

Pump wiring: Anytime the ignition switch is in the Run position and the test point is jumpered to ground, there should be at least 12 volts present on the black/pink wire. With power off, check the pump ground: you should see less than 1 ohm between the black wire and chassis ground.

The yellow wire is the fuel tank sender to the fuel quantity gage. The two black wires are grounds. One ground is for the fuel tank sender and the other is the fuel pump. The ground for the fuel pump may be larger gauge wire that the fuel tank sender ground wire.

Make sure that the power is off the circuit before making any resistance checks. If the circuit is powered up, your resistance measurements will be inaccurate.

You should see less than 1 Ohm between the black wire(s) and ground. To get some idea of what a good reading is, short the two meter leads together and observe the reading. It should only be slightly higher when you measure the black wire to ground resistance.

The Tan/Lt Green wire provides a ground path for the relay power. With the test connector jumpered to ground, there should be less than .75 volts. Use a test lamp with one side connected to battery power and the other side to the Tan/Lt Green wire. The test light should glow brightly. No glow and you have a broken wire or bad connection between the test connector and the relay. To test the wiring from the computer, remove the passenger side kick panel and disconnect the computer connector. It has a 10 MM bolt that holds it in place. With the test lamp connected to power, jumper pin 22 to ground and the test lamp should glow. No glow and the wiring between the computer and the fuel pump relay is bad.

Computer: If you got this far and everything else checked out good, the computer is suspect. Remove the test jumper from the ECC test connector located under the hood. Probe computer pin 22 with a safety pin and ground it to chassis. Make sure the computer and everything else is connected. Turn the ignition switch to the Run position and observe the fuel pressure. The pump should run at full pressure.

If it doesn't, the wiring between pin 22 on the computer and the fuel pump relay is bad.

If it does run at full pressure, the computer may have failed.

Keep in mind that the computer only runs the fuel pump for about 2-3 seconds when you turn the key to the Run position. This can sometimes fool you into thinking the computer has died. Connect one lead of the test light to power and the other lead to computer pin 22 with a safety pin. With the ignition switch Off, jumper the computer into self test mode like you are going to dump the codes. Turn the ignition switch to the Run position. The light will flicker when the computer does the self test routine. A flickering light is a good computer. No flickering light is a bad computer.

Remove the test jumper from the ECC test connector located under the hood.

Fuel pump runs continuously: The fuel pump relay contacts are stuck together or the Tan/Lt Green wire has shorted to ground. In extreme ghetto cases, the pump relay may have been bypassed. Remove the fuel pump relay from its socket. Then disconnect the computer and use an ohmmeter to check out the resistance between the Tan/Lt Green wire and ground. You should see more than 10 K Ohms (10,000 ohms) or an infinite open circuit. Be sure that the test connector isn’t jumpered to ground.

If the wiring checks out good, then the computer is the likely culprit.

Prior to replacing the computer, check the computer power ground. The computer has its own dedicated power ground that comes off the ground pigtail on the battery ground wire. Due to it's proximity to the battery, it may become corroded by acid fumes from the battery. It is a black cylinder about 2 1/2" long by 1" diameter with a black/lt green wire. You'll find it up next to the starter solenoid where the wire goes into the wiring harness

If all of the checks have worked OK to this point, then the computer is bad. The computers are very reliable and not prone to failure unless there has been significant electrical trauma to the car. Things like lightning strikes and putting the battery in backwards or connecting jumper cables backwards are about the only thing that kills the computer.

See the following website for some help from Tmoss (diagram designer) &

Stang&2Birds (website host)

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

http://www.veryuseful.com/mustang/tech/engine/images/88-91eecPinout.gif

That's a nice big garage! Congrats man.

I'll have to post a picture of my garage one day. Doby takes up everything. My wife is parking in the driveway......

That's a nice big garage! Congrats man.

I'll have to post a picture of my garage one day. Doby takes up everything. My wife is parking in the driveway......

Be honest Dave..

Doby is a workbench right now,isn't he?

Just picking on ya buddy

Actually, let me get a picture, she's kind of a storage facility for RobbyBe honest Dave..

Doby is a workbench right now,isn't he?

Just picking on ya buddy

Actually, let me get a picture, she's kind of a storage facility for Robby

Soooo where will you put Robby when it gets home?Actually, let me get a picture, she's kind of a storage facility for Robby

Where my wife parks in the drivewaySoooo where will you put Robby when it gets home?

Ok so I figured out why my fan wasn't coming on when the motor reached temp. I missed a tiny little detail in the instructions for the controller. I didn't run a wire to the ignition.  So here's my question about that. Where should I get that ignition signal from? Should I run it all the way back to the switch on the column or would it be ok if I got it from the ignition wire in the TFI harness that plugs into the module on the dizzy? Or should I get it from the one that plugs into the starter solenoid on the firewall? Is any one of these better/worse than the other? Depending on the where I mount my relay board I'm thinking that the one in the TFI harness would be most convenient.

So here's my question about that. Where should I get that ignition signal from? Should I run it all the way back to the switch on the column or would it be ok if I got it from the ignition wire in the TFI harness that plugs into the module on the dizzy? Or should I get it from the one that plugs into the starter solenoid on the firewall? Is any one of these better/worse than the other? Depending on the where I mount my relay board I'm thinking that the one in the TFI harness would be most convenient.

So here's my question about that. Where should I get that ignition signal from? Should I run it all the way back to the switch on the column or would it be ok if I got it from the ignition wire in the TFI harness that plugs into the module on the dizzy? Or should I get it from the one that plugs into the starter solenoid on the firewall? Is any one of these better/worse than the other? Depending on the where I mount my relay board I'm thinking that the one in the TFI harness would be most convenient.

So here's my question about that. Where should I get that ignition signal from? Should I run it all the way back to the switch on the column or would it be ok if I got it from the ignition wire in the TFI harness that plugs into the module on the dizzy? Or should I get it from the one that plugs into the starter solenoid on the firewall? Is any one of these better/worse than the other? Depending on the where I mount my relay board I'm thinking that the one in the TFI harness would be most convenient.Ok so I figured out why my fan wasn't coming on when the motor reached temp. I missed a tiny little detail in the instructions for the controller. I didn't run a wire to the ignition.So here's my question about that. Where should I get that ignition signal from? Should I run it all the way back to the switch on the column or would it be ok if I got it from the ignition wire in the TFI harness that plugs into the module on the dizzy? Or should I get it from the one that plugs into the starter solenoid on the firewall? Is any one of these better/worse than the other? Depending on the where I mount my relay board I'm thinking that the one in the TFI harness would be most convenient.

There's a wire on the wiper motor I tapped into . Red with green tracer it should be . Has key on. I went that far back cuz the harness I loomed was made to reach the solenoid so it wasn't much father to the wiper motor .

Sent from my iPhone using Tapatalk

I tapped into that one and it worked great. Thanks @TOOLOW91There's a wire on the wiper motor I tapped into . Red with green tracer it should be . Has key on. I went that far back cuz the harness I loomed was made to reach the solenoid so it wasn't much father to the wiper motor .

Sent from my iPhone using Tapatalk

A little bit of progress made today:

I think I set the timing to 10*. The lines on my balancer didn't have any numbers on it. I just set it to the middle line. I hope that's 10*.

So I let the car idle for a good 20 or 30 minutes. It maintained good temperature and I got the fan to come on at 190*. I love the throttle response of this engine!! I don't know if it's because the headers are still open or what but it's instant off idle. Oh and it's idling nicely at about 900 rpms.

So I let the car idle for a good 20 or 30 minutes. It maintained good temperature and I got the fan to come on at 190*. I love the throttle response of this engine!! I don't know if it's because the headers are still open or what but it's instant off idle. Oh and it's idling nicely at about 900 rpms.Ok, so now the issues that are still not resolved. It's still not turning over from the key. I did at least hear one of the solenoids click when I turned the key. I ran an 8-guage wire from the other post on the firewall solenoid to the unused post on the solenoid on the starter. The ignition wire is jumped from one solenoid to the other but it hangs up when I have it plugged on the post.

What the hell am I doing wrong?

What the hell am I doing wrong?The one and only leak is the power steering pump. It's leaking from somewhere around the shaft. WTF?

Other than that, no leaks.

Other than that, no leaks.

- Mar 2, 2015

- 6,822

- 5,859

- 203

That's for the cruise control module. If the wires lead to a grommet to the left of the clutch pedal then that's for cruise control. There should also be a vacuum line running from the brake pedal switch through that grommet as well.

mikestang63

SN Certified Technician

I tapped into that one and it worked great. Thanks @TOOLOW91

A little bit of progress made today:

I think I set the timing to 10*. The lines on my balancer didn't have any numbers on it. I just set it to the middle line. I hope that's 10*.So I let the car idle for a good 20 or 30 minutes. It maintained good temperature and I got the fan to come on at 190*. I love the throttle response of this engine!! I don't know if it's because the headers are still open or what but it's instant off idle. Oh and it's idling nicely at about 900 rpms.

Ok, so now the issues that are still not resolved. It's still not turning over from the key. I did at least hear one of the solenoids click when I turned the key. I ran an 8-guage wire from the other post on the firewall solenoid to the unused post on the solenoid on the starter. The ignition wire is jumped from one solenoid to the other but it hangs up when I have it plugged on the post.What the hell am I doing wrong?

The one and only leak is the power steering pump. It's leaking from somewhere around the shaft. WTF?Other than that, no leaks.

Spray some brake clean on the balance and clean it- that may help to read the numbers, If you can't you can buy a cheap tiiming tape from Summit that you peel and stick on your balancer. It is very important that you get the timing correct. Another way to check that it is at 10BTDC is look at the bottom of the dstributor housing where it meets the lower intake- the shaft has a mark and the intake has an arrow- line those up and you are at 10btdc. I also mark them with touch up paint so it's easy to stab it back in.

Oh, what's fuel pressure supposed to be at? I have it at 35 or 36psi. Should it be higher at idle?

mikestang63

SN Certified Technician

Oh, what's fuel pressure supposed to be at? I have it at 35 or 36psi. Should it be higher at idle?

38-41 with the vacuum line off and plugged

Similar threads

- Replies

- 1

- Views

- 395

- Replies

- 3

- Views

- 341

- Replies

- 18

- Views

- 2K

- Replies

- 44

- Views

- 5K

And my wife still has her parking spot.

And my wife still has her parking spot.