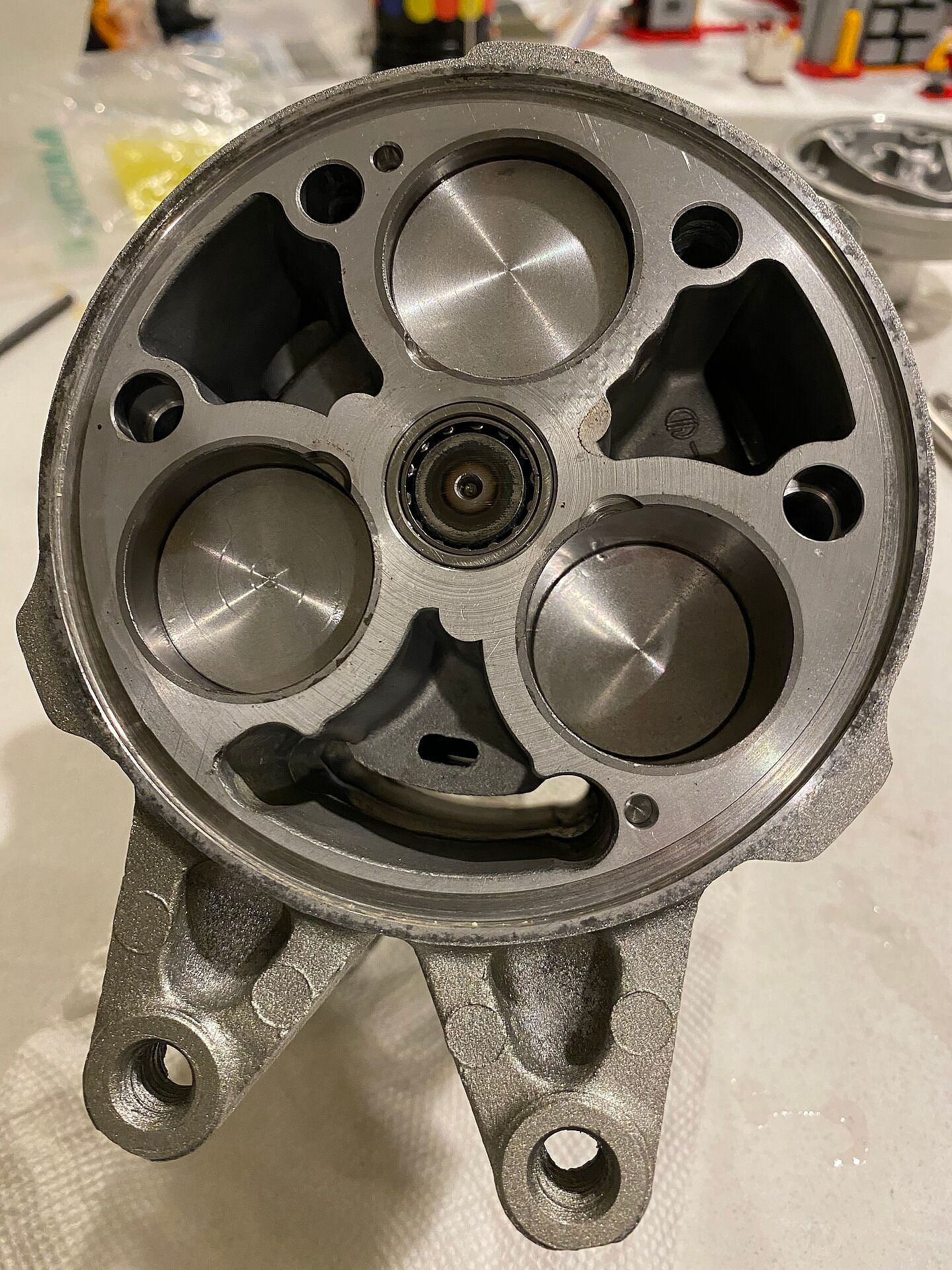

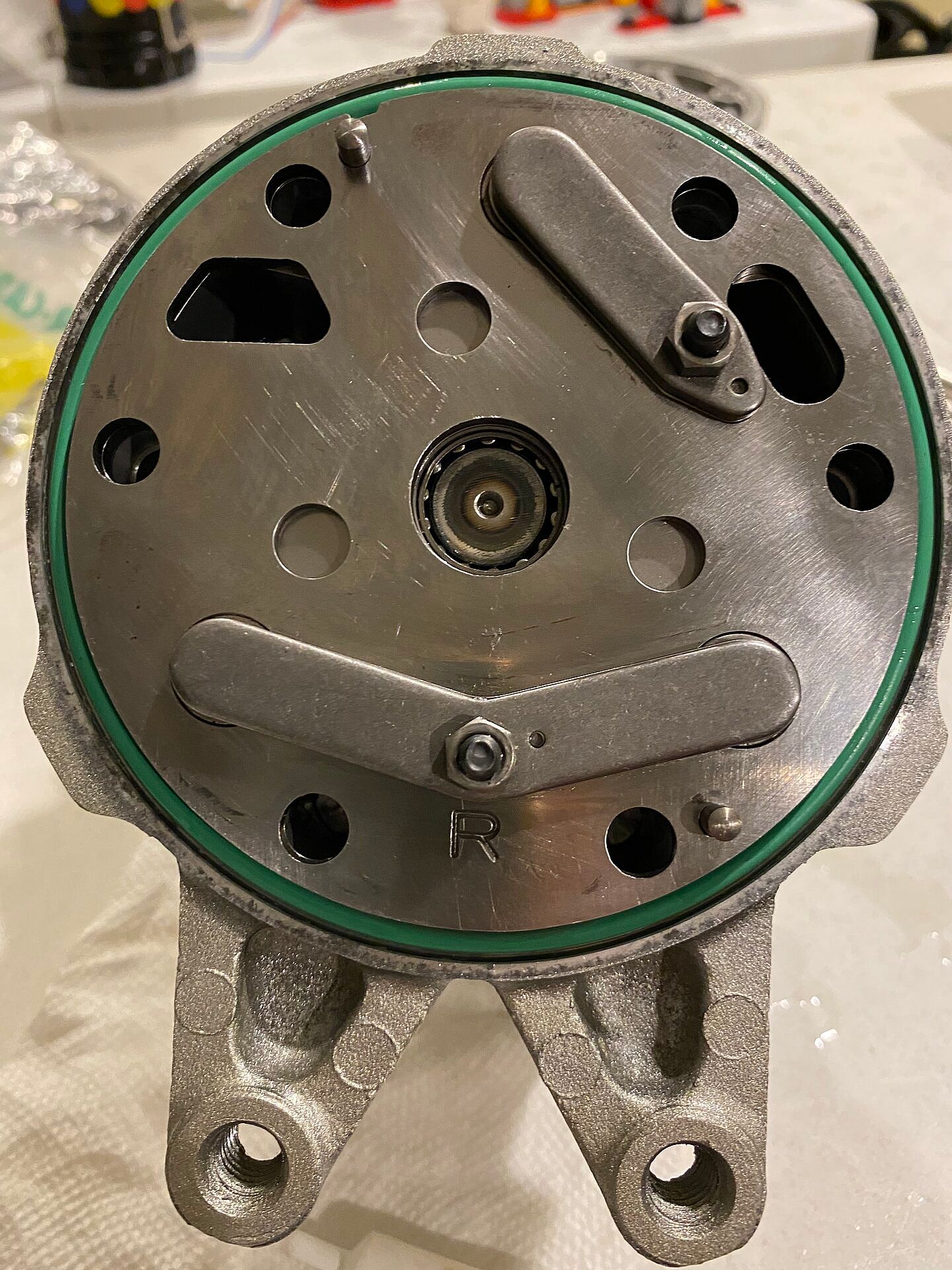

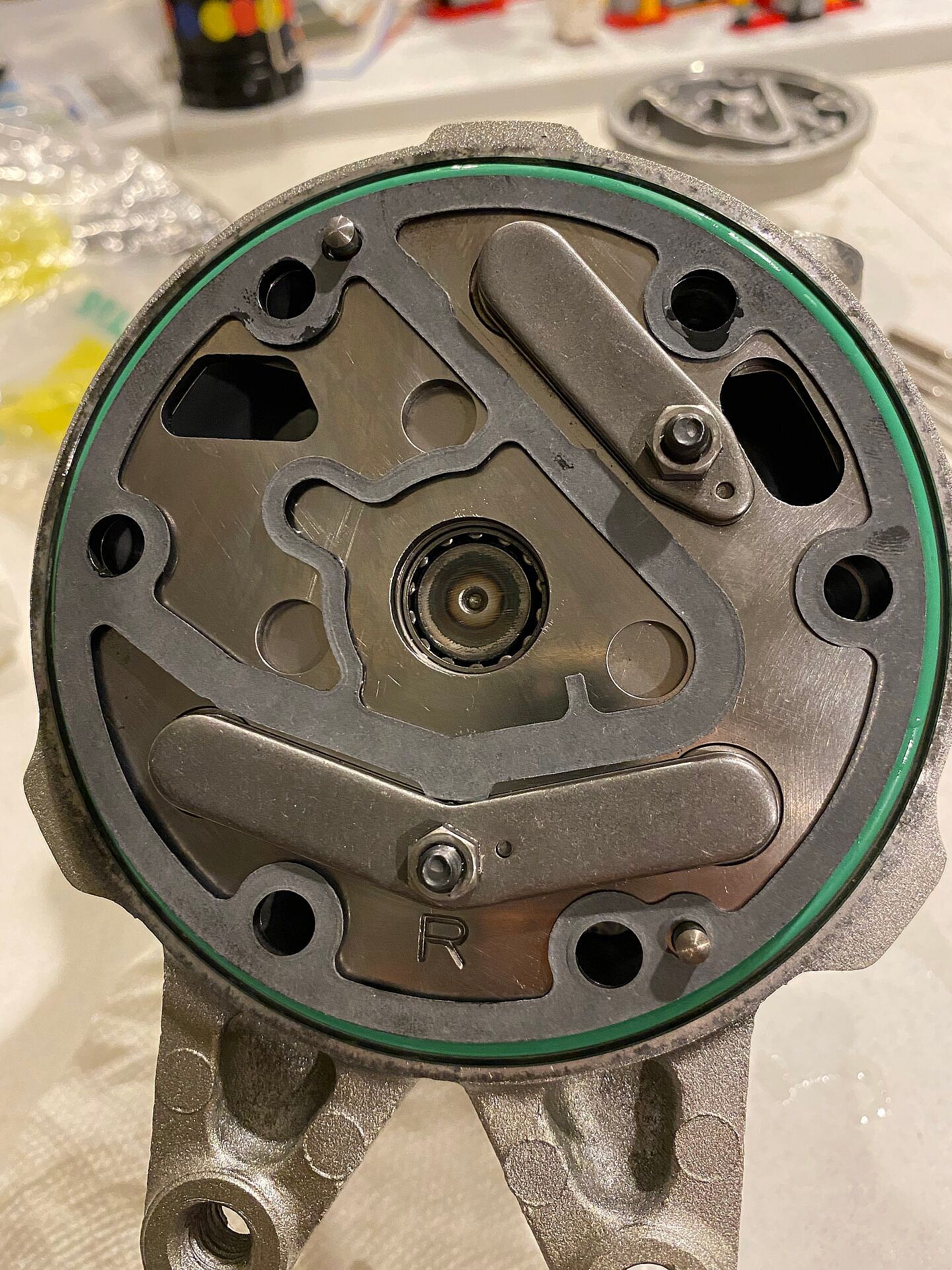

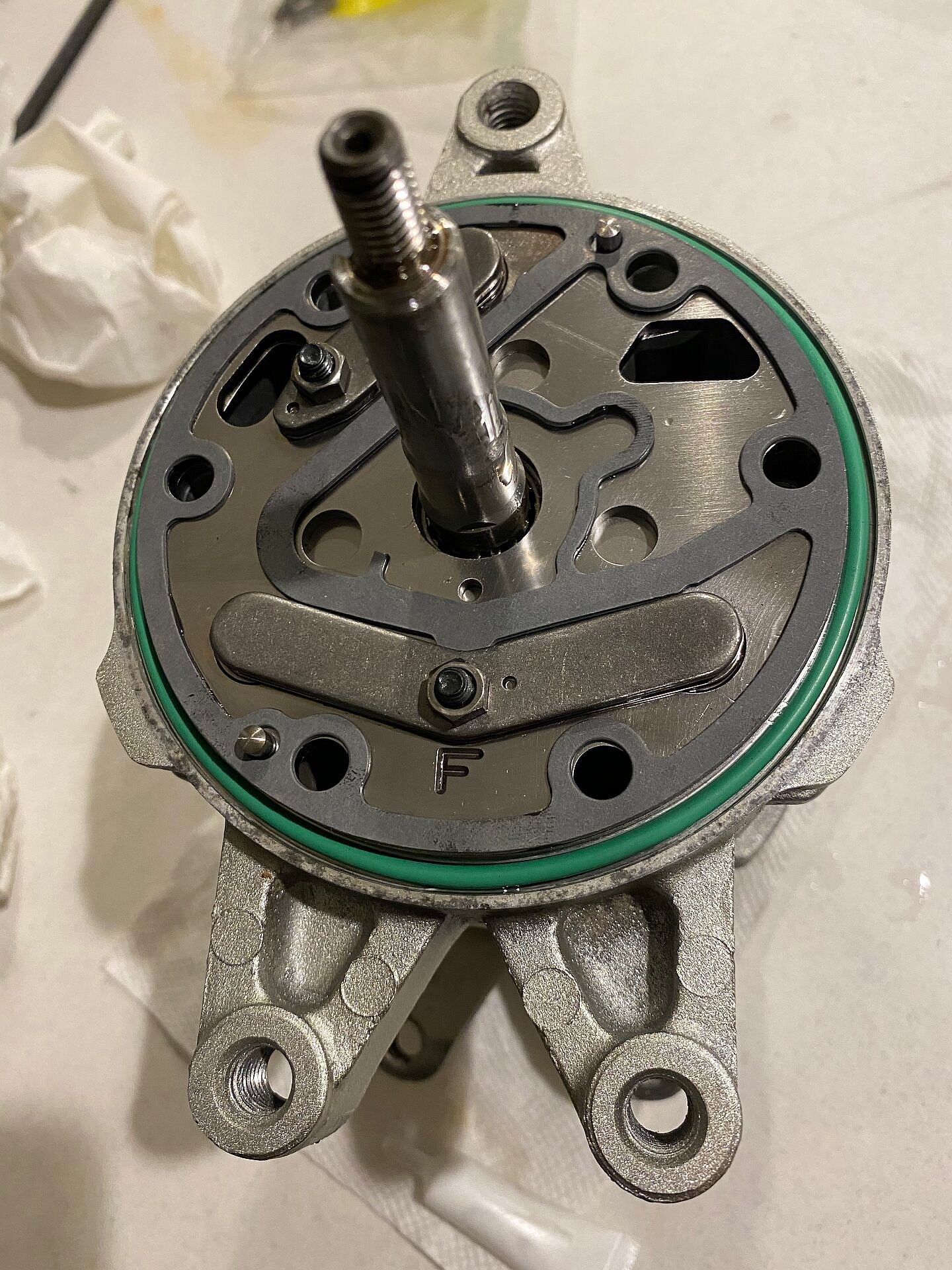

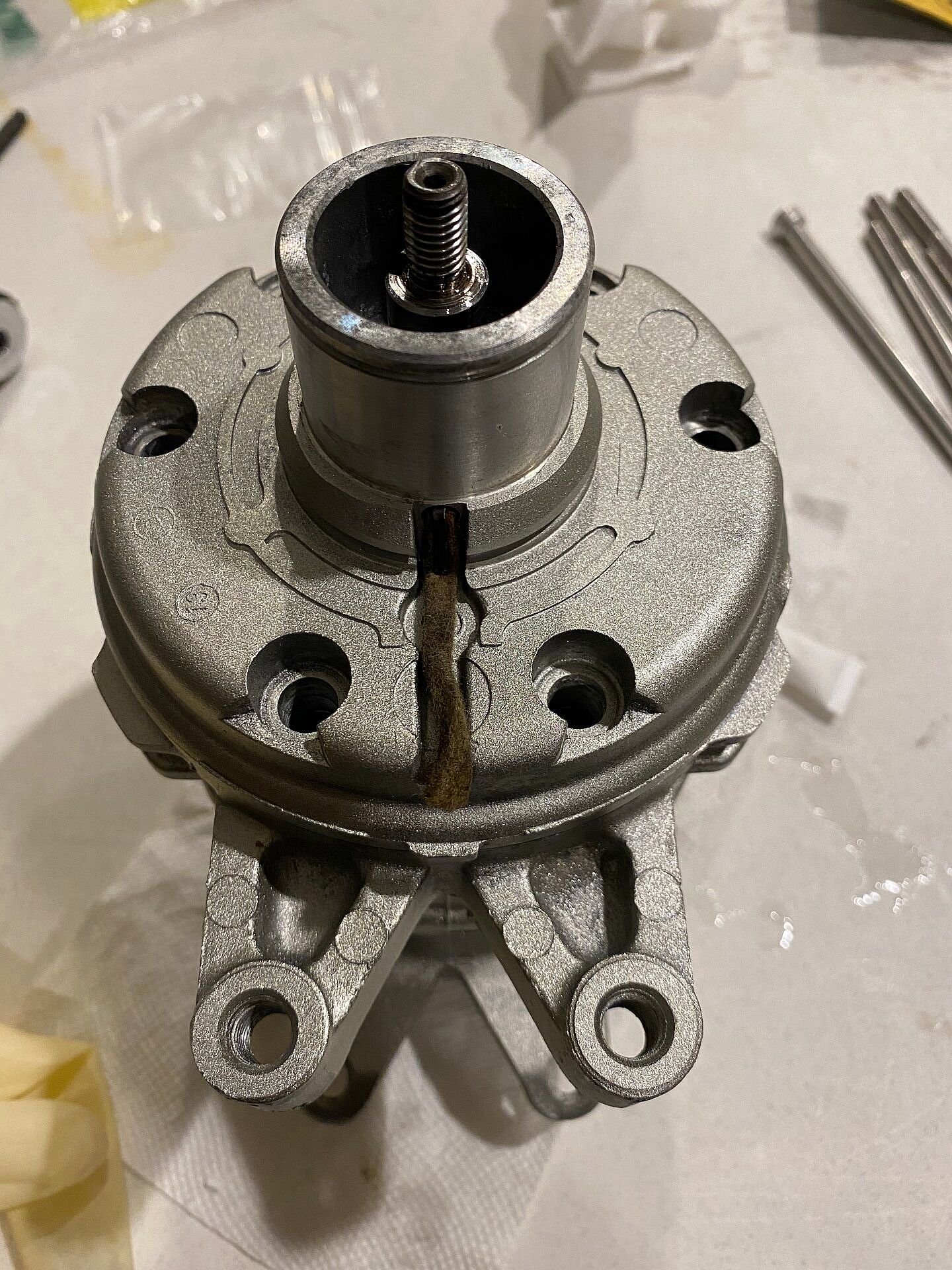

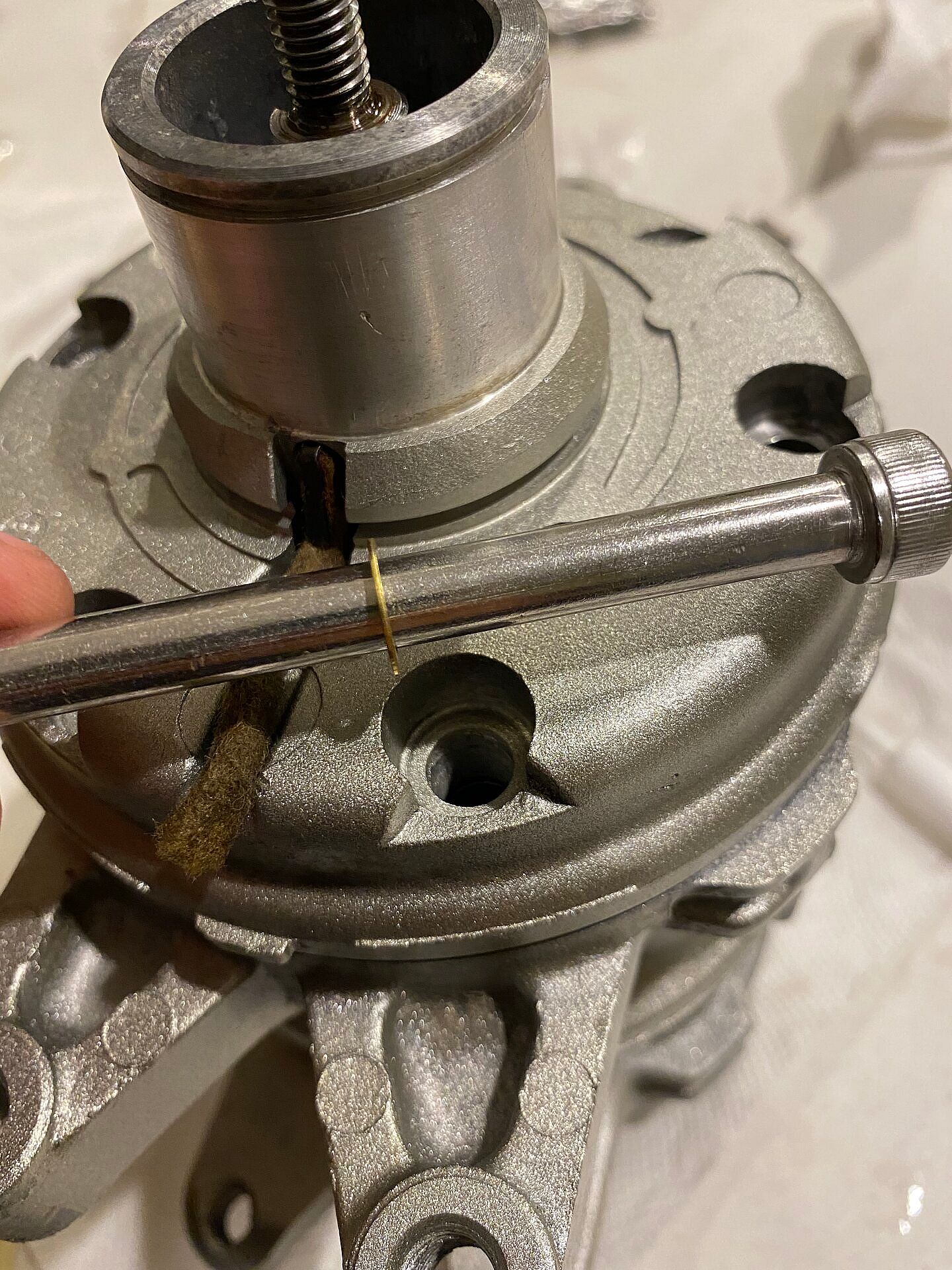

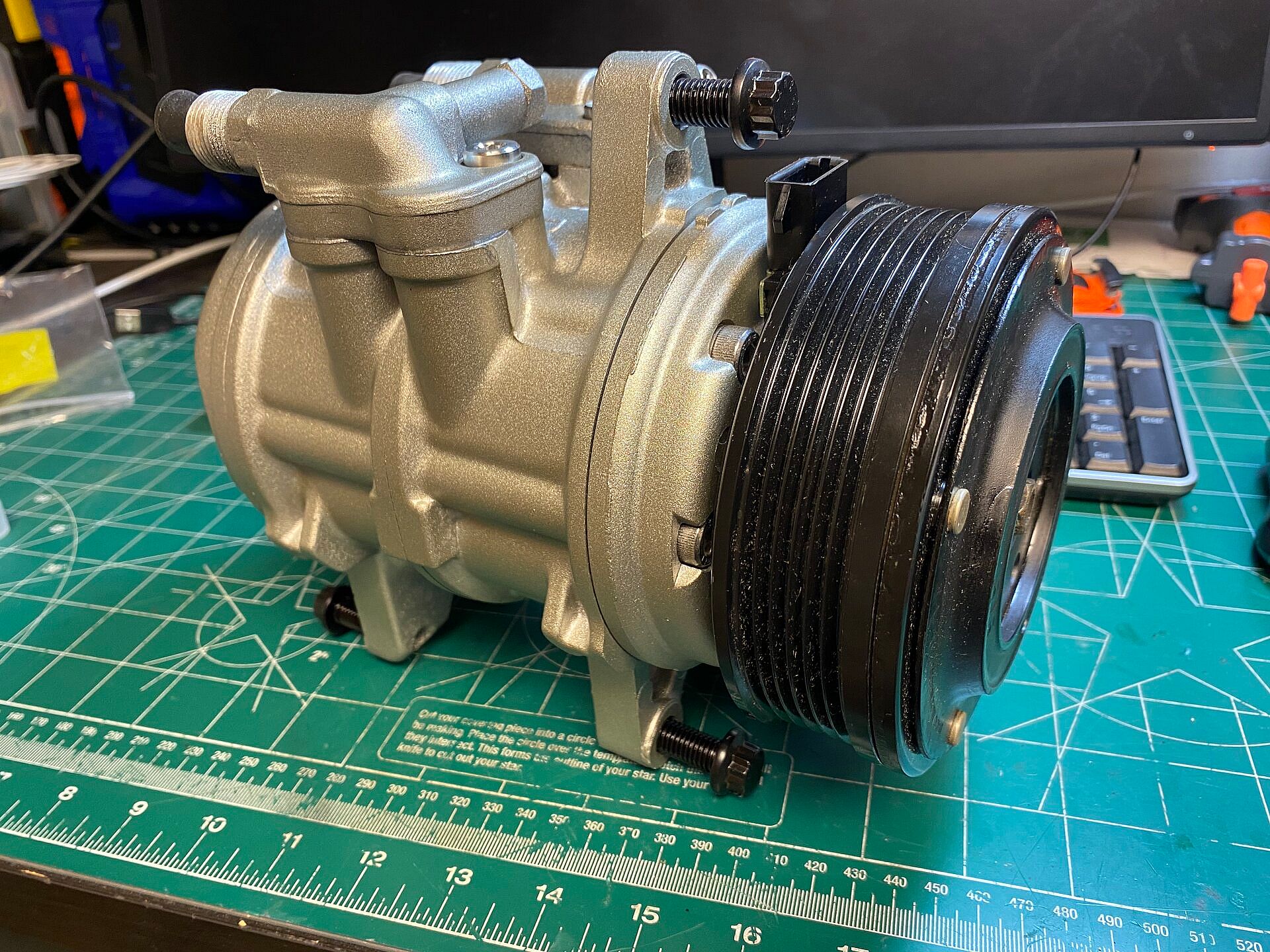

Reassembly time. I cleaned the internals with a clean lint-free rag and oil. You'll want to pay attention to the various surfaces the O-rings seal against and identify potential trouble areas.

Last edited:

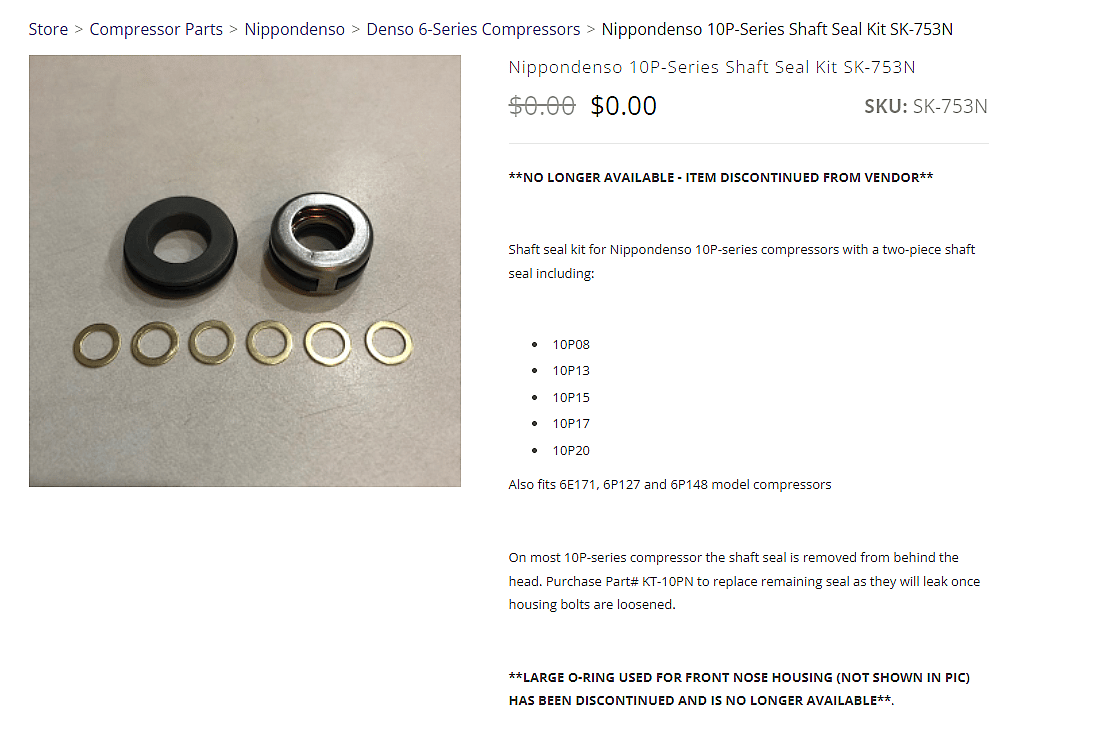

Does a person need to buy both gasket kits (Mt 2069 and mt 2140) from that site? From the picture it looks like you need parts from both?Looks like the source of the rebuild kits, Century Air, is defunct.

Searching "6P148A rebuild kits" I was able to find this source for $20

Just curious, where do the rebuilders get these unavailable parts?? Anyone know?Looks like all the parts are getting discontinued.

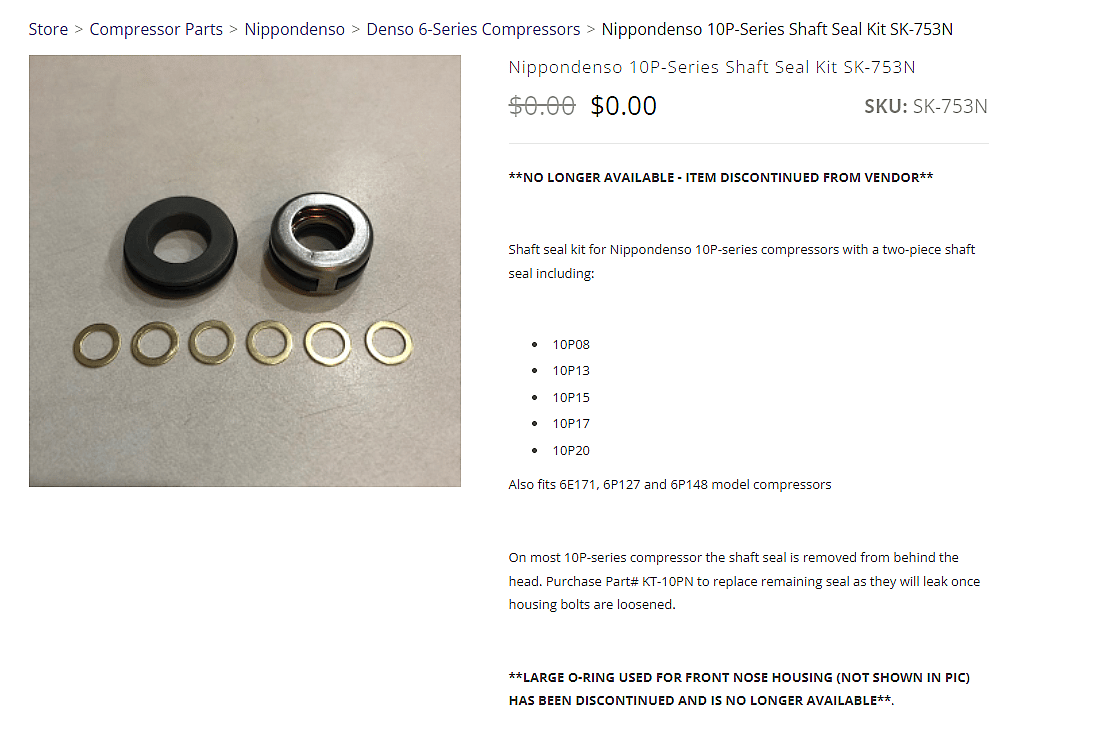

Here's the shaft seal that would have been normalled purchased. It says it's also compatible with the 6P127 which is listed above in that MT2069 kit. That shaft seal might work. Would need to actually try it out however.

Just curious, where do the rebuilders get these unavailable parts?? Anyone know?

First off, great write-up! I've already torn down two 6p148's and THEN I run into this thread. Anyway, looking to rebuild both to have 1 as spare for a fox I'm reviving ( or allowing for me to catastrophically mess up at least once) but I did notice that same exact ebay listing I had saved to my watchlist is now (a day later) sold out. Luckily, that shaft seal seems to be identical to this one and at least one other source already mentioned in this thread supports compatibility along with both the ebay listing and the rockauto page using the same picture (which alone isn't the most reliable). Ordered a pair of them and should be able to confirm fitment in a few days.I think this is the right shaft seal as well. Says last one left

A/C Compressor Shaft Seal for Denso 10P13 10P15C 10PA 6E171 6P148A Chrysler C171 | eBay

This seal will fit the following vehicles.www.ebay.com

I should prob pick up a kit and squirrel it away. In the grand scheme of things, $35 plus shipping isn’t much to rebuild the compressor