You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread Tannerc91gt’s Build(s) Thread

- Thread starter tannerc91gt

- Start date

-

Sponsors (?)

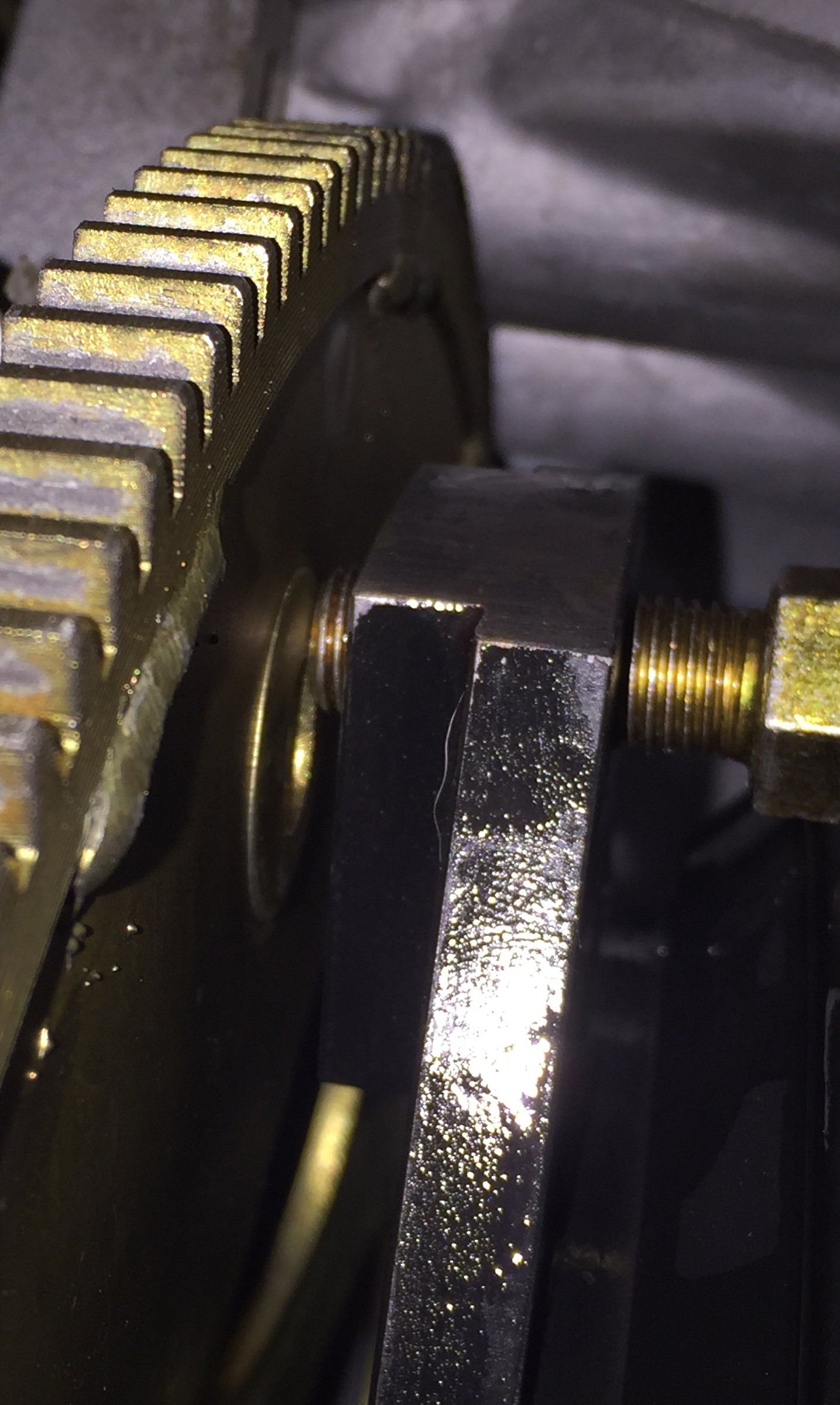

Basically an ls1 flexplate (i.e. 4l60e) has an 11.06" bolt pattern

Th400s and 80e's have the "big pattern" 11.5" diameter.

Although I ordered an ls1 converter it's drilled to the big pattern that most aftermarket flexplates are dual drilled for.

So while I technically didn't get what I ordered, my single pattern plate is the problem.

So it's down to buying a $300 flexplate or drilling/oblonging the holes on this one

Th400s and 80e's have the "big pattern" 11.5" diameter.

Although I ordered an ls1 converter it's drilled to the big pattern that most aftermarket flexplates are dual drilled for.

So while I technically didn't get what I ordered, my single pattern plate is the problem.

So it's down to buying a $300 flexplate or drilling/oblonging the holes on this one

So it's down to buying a $300 flexplate or drilling/oblonging the holes on this one

Yeah... That sounds like a great idea.

- Jul 7, 2005

- 1,563

- 1,197

- 164

So it's down to buying a $300 flexplate or drilling/oblonging the holes on this one

I thought flexplates were balanced?

Not saying it's what I'll do but it's not even remotely uncommon.Yeah... That sounds like a great idea.

minimal material removed equally across the flywheel. It would be fineI thought flexplates were balanced?sooooo would like make that a

Wait a minute.......

Why after having success w/ Holley's EFI system did you choose to take the road you're on? Granted, the MS3pro x is every bit as capable as that is, but the learning curve is killing you. If I had invested the money in that piece and was struggling to get the car running as much as you are,.....I'd have a carb on it. ( After just btchin Matt Cramer all up and down daily)

(Which makes me wonder how the 4 of us here that built kits have running cars w/ a close to very good tune w/ next to zero help from the fine folks at DIY auto tune.) Perhaps,......ummmmm,....because.......Steve??

Or.......

I think it's the "This engine don't belong here" gremlin,..payin a visit to claim his reward for your insolence...To think that you would invite certain doom, and risk a cursed remainder of your days all because you insist on putting the wrong engine in the right car, just boggles the mind.

Your balls must be so big you waddle when you walk.

Now,...even the simple sht is bitin your ass,....11.5" BC converters not fitting on 11" flexplates,....

This sounds like a page out of my build thread.

Only I gotta ford engine in my ford.

Why after having success w/ Holley's EFI system did you choose to take the road you're on? Granted, the MS3pro x is every bit as capable as that is, but the learning curve is killing you. If I had invested the money in that piece and was struggling to get the car running as much as you are,.....I'd have a carb on it. ( After just btchin Matt Cramer all up and down daily)

(Which makes me wonder how the 4 of us here that built kits have running cars w/ a close to very good tune w/ next to zero help from the fine folks at DIY auto tune.) Perhaps,......ummmmm,....because.......Steve??

Or.......

I think it's the "This engine don't belong here" gremlin,..payin a visit to claim his reward for your insolence...To think that you would invite certain doom, and risk a cursed remainder of your days all because you insist on putting the wrong engine in the right car, just boggles the mind.

Your balls must be so big you waddle when you walk.

Now,...even the simple sht is bitin your ass,....11.5" BC converters not fitting on 11" flexplates,....

This sounds like a page out of my build thread.

Only I gotta ford engine in my ford.

Ignoring all the mixed breed rambling, I've got a lot of friends (read guys that don't live anywhere near me) who had great success with the MS3. That has not been my luck. I've got it posted for sale to replace with the Holley system that I'm comfortable with. We'll see if it sells.Wait a minute.......

Why after having success w/ Holley's EFI system did you choose to take the road you're on? Granted, the MS3pro x is every bit as capable as that is, but the learning curve is killing you. If I had invested the money in that piece and was struggling to get the car running as much as you are,.....I'd have a carb on it. ( After just btchin Matt Cramer all up and down daily)

(Which makes me wonder how the 4 of us here that built kits have running cars w/ a close to very good tune w/ next to zero help from the fine folks at DIY auto tune.) Perhaps,......ummmmm,....because.......Steve??

Or.......

I think it's the "This engine don't belong here" gremlin,..payin a visit to claim his reward for your insolence...To think that you would invite certain doom, and risk a cursed remainder of your days all because you insist on putting the wrong engine in the right car, just boggles the mind.

Your balls must be so big you waddle when you walk.

Now,...even the simple sht is bitin your ass,....11.5" BC converters not fitting on 11" flexplates,....

This sounds like a page out of my build thread.

Only I gotta ford engine in my ford.

Steve was a big help, and his tune truly did make an obvious difference but it's still fighting to overcome some sort of perimeter or setting that I can't find. And frankly needing to pull my hair out trying to figure it out and the oh-so-helpful single sentence email responses from DIY and the phone they never answer has turned me away from it all together.

As of now, my interest in working on the car is dwindling as my frustration about various aspects of it grows so rather than pressing on until I decide to sell it, Im going to take a break for a while and wait for something to spark my interest in it.

Been full speed ahead since about august on this thing and it's burning me out.

If I could do what I really want I'd be cutting the front end off, moving the turbos out and redoing the coldside. That would fix my dump tubes being where I don't want them and my coolant hoses being jacked up like they are.

But it's not in the cards right now financially.

To-do:

Change EFI system

Fix turbo oil line

Setup rear end

Reroute starter/battery wiring

Build fuel pump mount

Fuel line solution (possibly sump tank)

Mount shifter

Modify/replace flexplate

Fix fuel leak

Reroute plug wires

Make mount for catch can

Cut holes in bumper for exhaust

Ignoring all the mixed breed rambling, I've got a lot of friends (read guys that don't live anywhere near me) who had great success with the MS3. That has not been my luck. I've got it posted for sale to replace with the Holley system that I'm comfortable with. We'll see if it sells.

Steve was a big help, and his tune truly did make an obvious difference but it's still fighting to overcome some sort of perimeter or setting that I can't find. And frankly needing to pull my hair out trying to figure it out and the oh-so-helpful single sentence email responses from DIY and the phone they never answer has turned me away from it all together.

As of now, my interest in working on the car is dwindling as my frustration about various aspects of it grows so rather than pressing on until I decide to sell it, Im going to take a break for a while and wait for something to spark my interest in it.

Been full speed ahead since about august on this thing and it's burning me out.

If I could do what I really want I'd be cutting the front end off, moving the turbos out and redoing the coldside. That would fix my dump tubes being where I don't want them and my coolant hoses being jacked up like they are.

But it's not in the cards right now financially.

To-do:

Change EFI system

Fix turbo oil line

Setup rear end

Reroute starter/battery wiring

Build fuel pump mount

Fuel line solution (possibly sump tank)

Mount shifter

Modify/replace flexplate

Fix fuel leak

Reroute plug wires

Make mount for catch can

Cut holes in bumper for exhaust

Sorry you are having such troubles brother- hopefully you will have a turning point with the MS and get it all straightened out.. Maybe even keep the stock front end you fought so hard not to chop off

All part of the game, it'll come around eventually. Have a lot of other great things going on right now that are taking up my time and attention

- Dec 19, 2010

- 5,719

- 4,238

- 224

Tanner, I'm very seriously looking at Holley HP efi myself right now. When I can get away from work long enough to reassemble my engine I'm giving MS one more very brief chance.. I'm almost certain it's going to go the way of the do-do. I know too many people that have holley and are in love with how simple it is, and how well it works.

As for that flexplate, would clocking it 45* and redrilling holes be doable, or do need a raised boss for the hole? If some plates come with multiple patterns, what's keeping you from making your own?

As for that flexplate, would clocking it 45* and redrilling holes be doable, or do need a raised boss for the hole? If some plates come with multiple patterns, what's keeping you from making your own?

Ignoring all the mixed breed rambling, I've got a lot of friends (read guys that don't live anywhere near me) who had great success with the MS3. That has not been my luck. I've got it posted for sale to replace with the Holley system that I'm comfortable with. We'll see if it sells.

Steve was a big help, and his tune truly did make an obvious difference but it's still fighting to overcome some sort of perimeter or setting that I can't find. And frankly needing to pull my hair out trying to figure it out and the oh-so-helpful single sentence email responses from DIY and the phone they never answer has turned me away from it all together.

As of now, my interest in working on the car is dwindling as my frustration about various aspects of it grows so rather than pressing on until I decide to sell it, Im going to take a break for a while and wait for something to spark my interest in it.

Been full speed ahead since about august on this thing and it's burning me out.

If I could do what I really want I'd be cutting the front end off, moving the turbos out and redoing the coldside. That would fix my dump tubes being where I don't want them and my coolant hoses being jacked up like they are.

But it's not in the cards right now financially.

To-do:

Change EFI system

Fix turbo oil line

Setup rear end

Reroute starter/battery wiring

Build fuel pump mount

Fuel line solution (possibly sump tank)

Mount shifter

Modify/replace flexplate

Fix fuel leak

Reroute plug wires

Make mount for catch can

Cut holes in bumper for exhaust

Well,...you certainly gotta know that I sympathize with your situation,.....It's not like I just threw my car together one day, and started it the next.

I was always under the understanding that there was a dedicated tech line for MS3, and the rest of us mortals had to suffer through the one line email responses. I too was getting frustrated in having to talk with them that way, seems every time I wrote them a complete description of the problem that took several paragraphs to describe,..the answer always came down to one sentence back from them.

Literally,.....If not for Steve, one of two things would be the case:

It'd have a carburetor on it.

It would be sitting.

Fortunately, I got lucky.....several times, In several situations.

I can say that it's real easy to get discouraged when tackling a build of this scope. It takes an attitude of "You're not gonna beat me" to get through it. Clearly, having the support of friends and the "panel of experts" from online communities like this one.

If I didn't have the sounding board to vent after spending countless hours getting filthy, or covered in body dust, whacking out when the car stopped running,..or simply because I wanted an opinion,...the Monster would be in a different place now...

Give it a break,...When I do that, I know that it doesn't take long before I'll want to go back down there and pick it up where I left it. Every single time I did that, I found the fix to the problem.

Like the dash bars....

I just couldn't figure out if I could make the idea work in reality from the idea that was in my head. I had already tried one path at home, and didn't like it. I was at a point where I was considering bailing on the idea altogether. (I wrote about my brain cramp on that dilemma here)

I let it sit...... right here..

Notice the 89 factory dash behind,...this was the original plan...To have the bars sit on top of the factory dash like an exo-skeleton...

stodgy, Integrated console,....I hated this plan, and had a ton of time in it...It was close, but disconnected.

We all went on vacation...I was riding in the passenger seat while the wife was driving us to MW-14. I was literally drawing the bars in the air with my finger,..when the solution popped into my head clear enough to make a concept drawing....and that led to the current config that is in the car.

It's a car that doesn't have to get you anywhere. Cool out and let it sit.... A day,..a week,...whatever. If you're like me, the problem solves itself a lot of times while I'm completely away from it.

Tanner, I'm very seriously looking at Holley HP efi myself right now. When I can get away from work long enough to reassemble my engine I'm giving MS one more very brief chance.. I'm almost certain it's going to go the way of the do-do. I know too many people that have holley and are in love with how simple it is, and how well it works.

As for that flexplate, would clocking it 45* and redrilling holes be doable, or do need a raised boss for the hole? If some plates come with multiple patterns, what's keeping you from making your own?

I'm on the small side of the ideal gap between the converter and flexplate so I could probably get away with that.

It's not uncommon to elongate the holes in this situation either. When you consider that the converter is centered by the input shaft and the bolts won't have any lateral slop I can't see ever noticing a difference.

PTC already tells you that you must drill out the holes for their 7/16 converter bolts but I was happy knowing I already had large enough mounting holes.

Jinxed myself.

I could pull the starter off and probably do it without having to pull the transmission again.

.... before you sell the system off....

I can give you a course on how to use, setup, configure and tune the system.

You already know the tuning basics through a different system, you will likely start to finish my sentences while we go over the tune.

Give me one hour, by the end of that hour if the car is not idling on its own I will concede defeat.

I can give you a course on how to use, setup, configure and tune the system.

You already know the tuning basics through a different system, you will likely start to finish my sentences while we go over the tune.

Give me one hour, by the end of that hour if the car is not idling on its own I will concede defeat.

The frustration associated with emailing DIYAT is pretty well documented here. I would definitely recommend calling them on the phone before I did anything else.

I appreciate that offer, and would still like to take you up on it. Given my connectivity issues, I can't really do anything with it as is..... before you sell the system off....

I can give you a course on how to use, setup, configure and tune the system.

You already know the tuning basics through a different system, you will likely start to finish my sentences while we go over the tune.

Give me one hour, by the end of that hour if the car is not idling on its own I will concede defeat.

After Cramer sent me a number to call (which no one ever answered I'll add) I sent DIY a lengthy email explaining my issues and what I've done attempting to correct it.

They responded with "try the serial, and don't use non-resistor spark plugs"

I'm using TR6s, they're not ideal for this application but for idling they should be fine. And they're a resistor plug.

So basically they told me to

off. Not sure I want to use their product and look forward to that future level of support.

off. Not sure I want to use their product and look forward to that future level of support.We will see, for now I'm just going to let it sit. If the MS doesn't sell for what I've got it listed at, I don't intend to take a bath on it so I'll find a way to make it work.

Again, not saying it isn't self induced, just that I don't feel I should have these kinds of issues with a startup tune supplied by them on something as simple as a cam-only 5.3 with stock injectors.

New TPS

New IAC

New Plugs

Checked for vacuum leaks

Changed coil packs

Tried multiple tunes

Tried multiple injectors

Tried 2 different throttlebodies

Retorqued intake manifold

We have fuel, spark, and by all accounts the correct amount of air.

Obviously something in that trio is not jiving

Still won't even idle. Just hums along at about 1500rpm with an occasional misfire.

Hello, mod dude.The frustration associated with emailing DIYAT is pretty well documented here. I would definitely recommend calling them on the phone before I did anything else.

What they are referring to are the serial port connections. Typically it's a db9 connection, you then use an rs232 converter to usb...

Most likely the port configuration on your laptop are incompatible. Or to slow to run the connection with feedback.

You will need to access the port options in the control panel.

the port you have the ECU connected to needs to have (all setable)

-Baud rate 11500 minimum.

-set the port to port1 (not necessary but helps)....

Try the serial port connection.

Most likely the port configuration on your laptop are incompatible. Or to slow to run the connection with feedback.

You will need to access the port options in the control panel.

the port you have the ECU connected to needs to have (all setable)

-Baud rate 11500 minimum.

-set the port to port1 (not necessary but helps)....

Try the serial port connection.

I have avoided saying anything about MS because so many on here are using their product. My observations have been---if it weren't for Steve,there would be a few others really really unhappy with that product. Very common issues with DIY support. I'm not trying to be a "told you so" but I'm going to anyway lol. I would have bought the Holley system

Similar threads

- Replies

- 11

- Views

- 2K

Progress Thread

Make the Notchback Great Again!

- Replies

- 24

- Views

- 3K

- Replies

- 13

- Views

- 834

- Replies

- 2

- Views

- 797