All you gotta do, is write a simple to understand, comprehensive manual to understand how to tune in Tuner Studio.

If somebody would undertake the task of converting all of that techno crap, and turn it into lay speak, label the book "TUNER STUDIO FOR DUMMIES" and keep it that way...you'd have to start smoking cigars.

Because you'd need a way to dispose of all the extra twenties you'd have laying around........Nothing lights a Macanudo better than a rolled up 20 dollar bill.

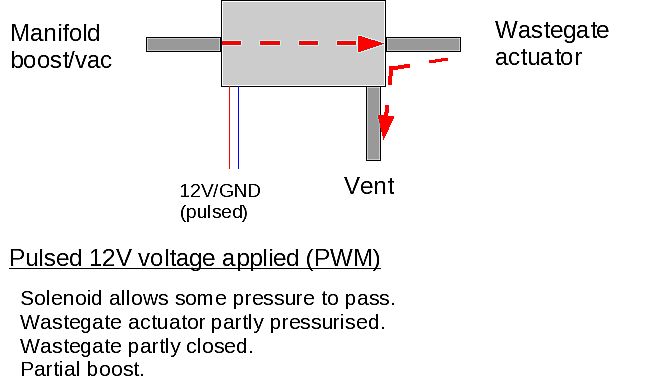

I swear,...Why is this so freakin hard? Somebody PLEASE find me anywhere out there where the process (starting from scratch) of enabling the boost control mod, picking which setting to use, (and understanding why you did) i.e. closed loop, or open loop...then setting up the boost control duty table (open loop) or the boost control target table (closed loop) respective of that choice.

This is why people shy away from using this system,....You have to have an advanced understanding of electronics, computers, techno-speak,...and be willing to risk turning several thousand dollars into a smoldering pile of ash if you don't.

I built this thing from a bunch of baggies with doo-dads in them...I soldered every little jinky doo into every little ding dang deal that the online manual told me to do. When it came time to start the damn thing,..the car almost started on the first crank....

But,...can I tell you why it did?......Hell no. I just must be one of the lucky ones.

But after you build it,...NOW you gotta get the car running,....NOW you have to know how to "tune" it,... And therein lies the problem...

If there was just a book,....written in the same style of all of the rest of the "For Dummies" books out there that doesn't talk techno jargon, and doesn't ASSUME that you know what you're doing,....then maybe.......Just maybe DIY Auto Tune would be the first choice in 10, instead of the 7th or 8th when picking an aftermarket ECU conversion.

Who wants a million dollars?

If somebody would undertake the task of converting all of that techno crap, and turn it into lay speak, label the book "TUNER STUDIO FOR DUMMIES" and keep it that way...you'd have to start smoking cigars.

Because you'd need a way to dispose of all the extra twenties you'd have laying around........Nothing lights a Macanudo better than a rolled up 20 dollar bill.

I swear,...Why is this so freakin hard? Somebody PLEASE find me anywhere out there where the process (starting from scratch) of enabling the boost control mod, picking which setting to use, (and understanding why you did) i.e. closed loop, or open loop...then setting up the boost control duty table (open loop) or the boost control target table (closed loop) respective of that choice.

This is why people shy away from using this system,....You have to have an advanced understanding of electronics, computers, techno-speak,...and be willing to risk turning several thousand dollars into a smoldering pile of ash if you don't.

I built this thing from a bunch of baggies with doo-dads in them...I soldered every little jinky doo into every little ding dang deal that the online manual told me to do. When it came time to start the damn thing,..the car almost started on the first crank....

But,...can I tell you why it did?......Hell no. I just must be one of the lucky ones.

But after you build it,...NOW you gotta get the car running,....NOW you have to know how to "tune" it,... And therein lies the problem...

If there was just a book,....written in the same style of all of the rest of the "For Dummies" books out there that doesn't talk techno jargon, and doesn't ASSUME that you know what you're doing,....then maybe.......Just maybe DIY Auto Tune would be the first choice in 10, instead of the 7th or 8th when picking an aftermarket ECU conversion.

Who wants a million dollars?

Last edited:

ticket sales

ticket sales  online videos

online videos