trinity_gt

10 Year Member

Did some more checking. I don't think it's the belt I've shown above. With the covers off I lubed up some moving points, went back and plugged it in and inspected the mechanism as it went through it's dance and it seemed to work flawlessly for me. (Hafta say that is one complex mechanism...)

I went back and screwed the covers back on and tried it again and got all sorts of "cd error"s again. After a while, it seemed to work okay again though it seemed like once in a while I did have to tap the side of the console to get it to spit a CD out.

I dunno... I'll keep digging when I have time to see if there's any sort of mechanical issue related to the covers or being screwed back in place that might interfere with the operation of the changer. Very strange.

(Sorry this is so long...)

Back from the dead. I have a new theory I thought I'd share for those masochists out there still using the CD6.

The day after I got the car out of storage I took the radio out and had another go at the 6-disc changer and, like I said, have a new theory. Interestingly, the bolded text above hints at what I believe is "a" problem if not "the" problem.

I went through the same process of removing the CD changer from the radio, removing its cover and inspecting it. I plugged the two connectors back in but left the changer sitting atop the radio chassis and went back out to the car to do some checks in situ. I noted again that the changer seemed to work fine in this configuration. It took a few cycles for the mechanism to achieve proper initialization (it had been left in a truly screwed up state) but once initialized it seemed to load, play and eject CDs from all 6 slots.

I watched the mechanism more closely and think I made a significant finding. First some background:

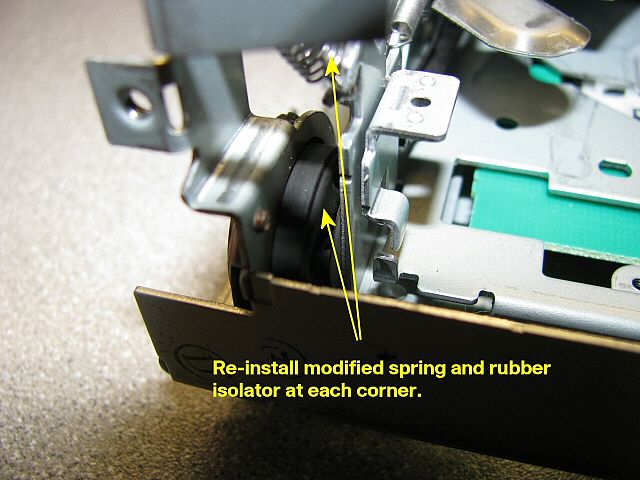

The changer mechanism is mounted to the changer chassis with four (4) rubber mounts. The mechanism is suspended with 4 springs, one at each corner and together these springs and the rubber mounts help isolate the mechanism from vehicle bumps and vibrations that would otherwise cause skipping. The changer mechanism (already noted as being fiendishly complex) goes through a crazy sequence of moves, some of which involve the entire assembly moving "upward" in the chassis. In my case, I saw that the mechanism moved in an entirely implausible way: The mechanism actually moved such that the innards ended up being higher than the top of the chassis. In fact, on its way it bumped into a part of the chassis and binded a bit before moving past toward the top of the movement. I got to thinking that if the top cover was in place the mechanism would strike the top and not have been able to move any further, constrained by the metal of the top cover. Indeed, there are witness marks on the top cover attesting to this interference. When bound like this I surmise the mechanism is unable to complete the move and faults -- perhaps it times out or hits a current limit on a stalled motor. Belts may also slip resulting in a loss of synchronization.

With the top removed, the mechanism is (almost) free to move as it should which might explain why, when the top is off and I'm trying to see what's wrong, the thing seems to work.

I then looked closer to see what could cause this. I appeared that the springs were not extended at all and that the flexible rubber mounts were basically near the limit of their flexibility toward the top. In short, the mechanism is being held up by the springs and "weak" rubber mounts whereas I think these mounts are supposed to be more "centered", allowing the mechanism to sit more in the center of the changer chassis. If this were the case the mechanism could move all the way to the top of its travel without hitting other metal.

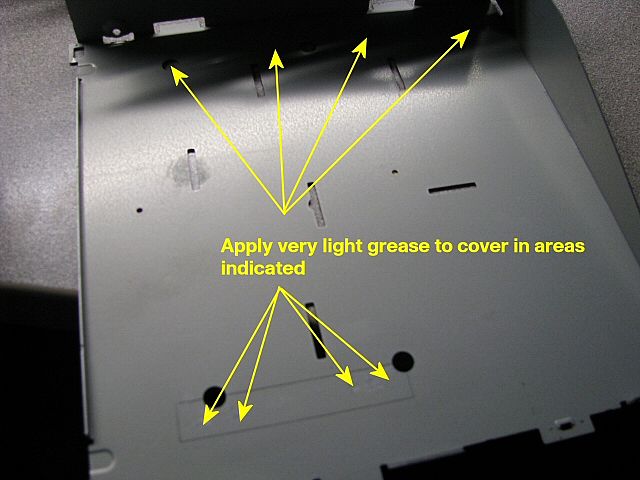

So I took the springs out and stretched them just a little bit to allow the mechanism to sag a bit in the chassis. I re-installed them, cleaned the laser pickup with a Q-tip and alcohol and put a wee bit of lube on the mechanism points I could reach. I put the top cover back on and tried it and it continued to load, play and eject from all 6 slots.

So far so good. I've got it back into the radio and the radio slid back into the dash but haven't had the time to play with it much more yet and the weather's been soooo

ty here I haven't driven the car yet so I don't know if this is "real" or just a fluke.

ty here I haven't driven the car yet so I don't know if this is "real" or just a fluke.It makes sense to me that the rubber mounts would soften up over time and allow the springs to pull the mechanism upwards and, further, that the mechanism would be insufficiently powerful enough to force it back down against the springs when the mechanism needed to move all the way to the top.

Only time will tell I guess. Hopefully this isn't just a flakey works-for-a-day thing.

I can pull it out and take some more pics showing what I'm getting at if anyone is interested. Might help to have a few intrepid souls try this on CD6s showing "CD error" to see if it's repeatable.