Here is an update. I had planned to be done the project as in Feb but didn't happen. This past weekend I finished the fuel system and electrical is on its way. Also have the exhaust together and brake lines have been run. Once the electrical is complete and fluids topped off I will be on the road after a long eight months. Here are pics with some updates.

This was the mustang August 2009.

The following pics are recent

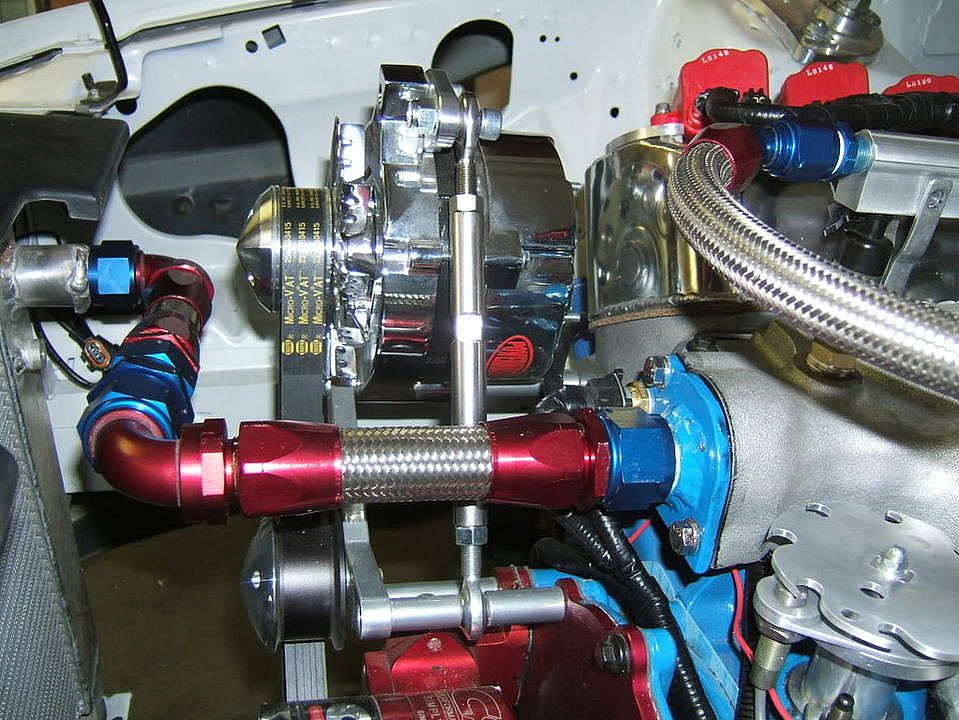

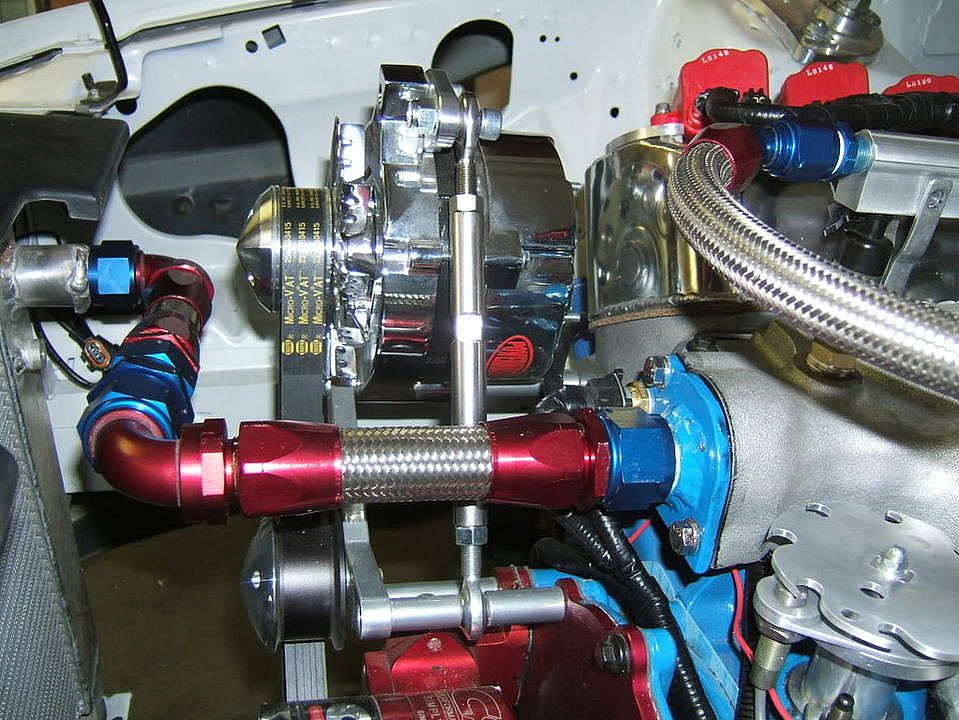

I fought with my cooling system a bit. I turned on the water pump to find that the water ports at the rear of the block did not seal to the manifold. I didn't know if water got into the engine so I drained all the oil which was painfully slow as it is break in oil to ensure there was no water. Couldn't see any so I just put it back. I think the little rust was when I pulled the intake. Anyway I had to pull off the intake but used this opportunity to tap a port for my brake booster and MAP sensor. So it was worth it.

The lower rad hose I found a 90 degree bend tube of aluminum I used for a lower rad hose. There was lots of straight of the 90 so I only have about four inches of goodyear rad hose on each side of the tube to their respective terminations. The upper rad hose was a different story. I went for bling bling. I welded a a bung on to some plate and tapped my coolant sensor for my ECU to poke through where the existing heater hose would go. I put together a -16an with fitting that my buddy had lying around from his past nascar team. Turned out real nice!

The thing I really worked on this week was the fuel system. I decided a fuel pump in a gas can hanging out the side was not going to cut it. Plus it was getting in the way. Here was my fuel system adventure.

That same friend with the nascar team had some outdated kevlar race cells. The things are worth about 3000 new! This one was three years old and recertification costs as much as a new one so I picked this up for 100 bucks. So I had to make this fit in a hole I cut in my trunk. I wanted to keep the weight as low as possible.

This was the hole I cut in my trunk to get rid of the wheel well

I welded "canstrut" strut that holds spring nuts across my frame in the rear and then welded together an aluminum box to hold the fuel cell. I made it out of 1/8 thick aluminum and really got it tight to the canstrut to add to the structural integrity of the rear.

A pic of the bag sitting on the box

Everything fit in nicely

The bottom of the cell is about 1/2" above the bottom of the bumper. Hides in nicely. and I actually used the box to bolt my fuel pump to.

This took some work. The cell was built for nascar so I had to add a return line, fit in a fuel sender, and put in a smaller breather due to space constraint. I had to take it apart once I realized I was a retard and put gasket goop on the fuel system part. I pulled it apart and made cork gaskets. fun fun.

It fits!!

This is after I buttoned the lines and batter cable under the car and brought them into the trunk. I am happy with it

I am back at work now for three weeks! So the car will be on the road late May due to this, but here is where I left the car. The interior is still somewhat apart and not cleaned because there is still electrical to run.

Cheers

This was the mustang August 2009.

The following pics are recent

I fought with my cooling system a bit. I turned on the water pump to find that the water ports at the rear of the block did not seal to the manifold. I didn't know if water got into the engine so I drained all the oil which was painfully slow as it is break in oil to ensure there was no water. Couldn't see any so I just put it back. I think the little rust was when I pulled the intake. Anyway I had to pull off the intake but used this opportunity to tap a port for my brake booster and MAP sensor. So it was worth it.

The lower rad hose I found a 90 degree bend tube of aluminum I used for a lower rad hose. There was lots of straight of the 90 so I only have about four inches of goodyear rad hose on each side of the tube to their respective terminations. The upper rad hose was a different story. I went for bling bling. I welded a a bung on to some plate and tapped my coolant sensor for my ECU to poke through where the existing heater hose would go. I put together a -16an with fitting that my buddy had lying around from his past nascar team. Turned out real nice!

The thing I really worked on this week was the fuel system. I decided a fuel pump in a gas can hanging out the side was not going to cut it. Plus it was getting in the way. Here was my fuel system adventure.

That same friend with the nascar team had some outdated kevlar race cells. The things are worth about 3000 new! This one was three years old and recertification costs as much as a new one so I picked this up for 100 bucks. So I had to make this fit in a hole I cut in my trunk. I wanted to keep the weight as low as possible.

This was the hole I cut in my trunk to get rid of the wheel well

I welded "canstrut" strut that holds spring nuts across my frame in the rear and then welded together an aluminum box to hold the fuel cell. I made it out of 1/8 thick aluminum and really got it tight to the canstrut to add to the structural integrity of the rear.

A pic of the bag sitting on the box

Everything fit in nicely

The bottom of the cell is about 1/2" above the bottom of the bumper. Hides in nicely. and I actually used the box to bolt my fuel pump to.

This took some work. The cell was built for nascar so I had to add a return line, fit in a fuel sender, and put in a smaller breather due to space constraint. I had to take it apart once I realized I was a retard and put gasket goop on the fuel system part. I pulled it apart and made cork gaskets. fun fun.

It fits!!

This is after I buttoned the lines and batter cable under the car and brought them into the trunk. I am happy with it

I am back at work now for three weeks! So the car will be on the road late May due to this, but here is where I left the car. The interior is still somewhat apart and not cleaned because there is still electrical to run.

Cheers