I have the piston rings [total seal gapless] 357 cid is plenty for the parts i have to build it with... here is a run down..

-my ported 2.02/1.6 GT40 irons with 7/16 studs and guide plates [unless a money tree sprouts from the yard somewhere]

-My M112 blower setup, on a 357 it will make around 8psi with very little intake heating and less pressure means less parasitic loss

-my billet cam 575 lift 224i/236e custom grind ....... after talking with the cam grinder he thinks it will work very well in the 357 but wont be enough cam in a 393+

The main purpose of the 351 build is to get the stoutness of the block without going dart, the stock crank and truck rods will handle stupid power.

I'd use the pistons and rings, and have it lazer profiled to meet the Total Seal requirements.

My first Cleveland 351c build in 1988 was a forged engine failure due to piston to bore clearance.

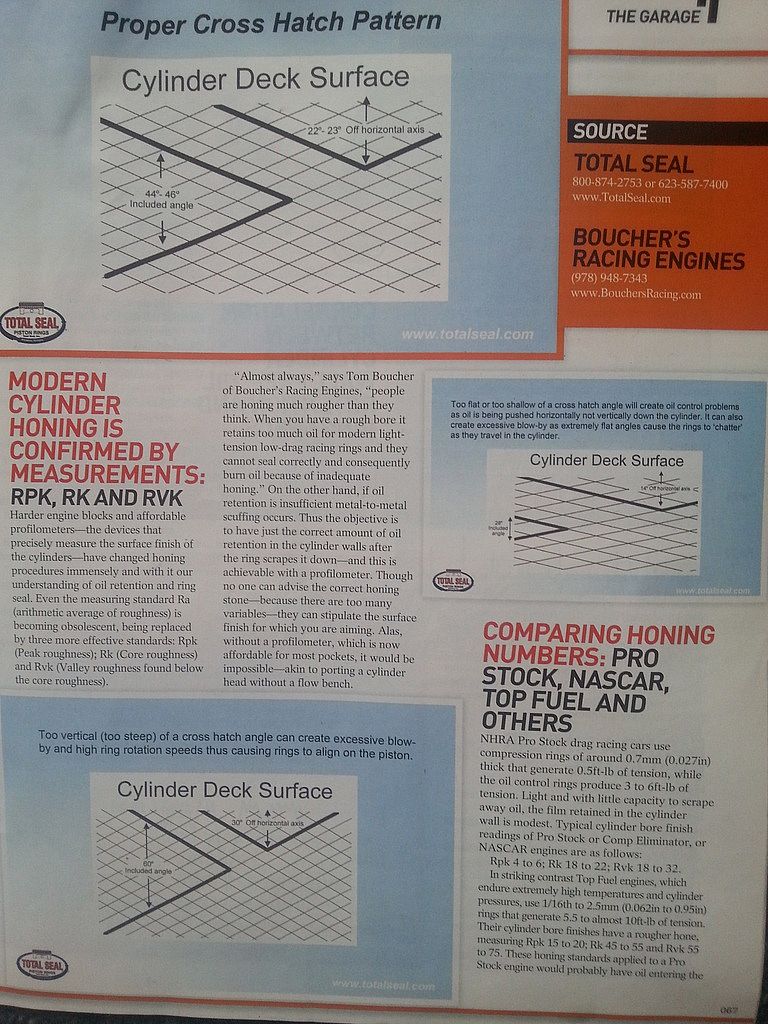

First, you must use for the pistons you have, the right bore and ring gap specs. Before it gets to that point, you must have the bore texture right when it reaches the final 4.030 bore target. You do that by plateau honing.

This is not an advertorial, and please excused me if I'm Book Bashin' ya Steve.

A complete list of honing procedures, recommendations and tech tips are available at

www.hastingspistonrings.com/tech-tips-faqs,

www.totalseal.com or

www.sunnen.com/honing-tips.

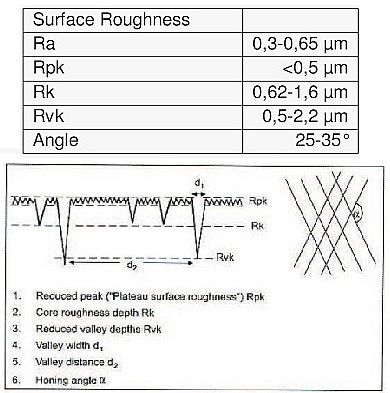

Definitions:

Profilometer – an instrument used to measure a surface's profile in order to quantify roughness. A contact Profilometer records a surface profile by moving a diamond stylus across a specified distance, with a specified contact force.

Rk – The average core roughness depth based on the Rpk and Rvk measurements.

Rpk – The mean height of peaks protruding from the roughness core profile.

Rvk – The mean depth of the valleys protruding from the roughness core profile.

Rz – The mean highest peak-to-valley measurement taken from five samples.

General gist of it is here:

http://www.laneautomotive.com/lanemobile/techpeaksandvalleys.html

Total Seal diagram below (a better one is in the three page blurb below copied from Issue 129 of Australian Street Fords).

The deep scores are the valley cross hatching, the rest is in the plateau hone to smoothen 45 degree included angle cross hatch so you get the right relief map for the rings to flow against the moderate boundary layer of oil.

The critical measurements are not average peak to peak roughness, but the boundary layer surface texture figures.

Plateau honing a cylinder block is how the boundary layer is endorced.

A Sunnen Laser profilometer measures the Rpk, Rk and Rvk.

If you've gotten valve springs and piston to valve clearance right, the main and cam bearings right, and the rods right, and you've tuned it out of the incipent detonation era, then all engine failures in Windsors are blow by matters due to not following the modern laser profile requirments.

A lot like peak CFM figures, Ra averages are useless for setting good bore texture. Sunnen suggest that "brushing the bore after honing makes a huge improvement in the surface finish, whether diamonds or conventional honing stones were used to hone the bore. You can get the overall Ra down to 8 to 12, with RPK (relative peak height) numbers in the 5 to 15 range, and RVK (relative valley depth) numbers in the 15 to 30 range."

The Rpk, Rk and Rvk are the figures to aim for, Not Ra.

NASA totally nailed lubrication and surface roughness calculations. When building a 351 from parts, the latent value of an iron block in the hand can be kept by going through the science of cylinder bore prepartion.

As for the intake, I'd use what you have, but consider how you air flow limited the GT40's are, and the lower intake is. Injector postions, well it'll change if you make up adaptor plates.

Your excellence in MS-ing it can be backed up by others in the building process.

I am an advocate of aftermarket blocks, because if you break one, it'll still have residual value. However, in your case, the 351 W block can be gusseted by the upper location strakes and the lower girdle in the pictures in my previous posts.

The lower crank girdle, and plateau honed block were standard ways Ford Australia tied a low quality thin wall 5 liter Windsor together to turn it into a 5.6 stroker.

Read this, and then get the piston to bore texture right.