Aside from the SVO forum, this is likely the best place to ask I figure.

For any of you 2.3 guys that have done an upgrade T5 swap from the questionable 4cyl box to the V8, how far have you milled the input shaft?

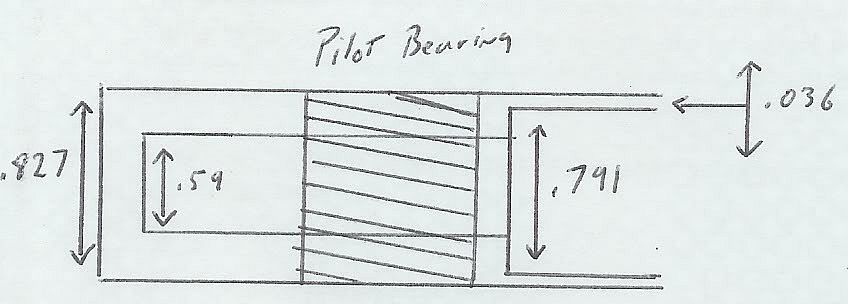

The shaft I had taken to a local machine shop wasn't milled all the way to the shaft teeth. It's basically tapered on the pilot bearing tip. If you can imagine what a stock V8 shaft tip looks like, the larger inner surface should be something like .791 and the end a .668. I had the end milled to .59 but the shop left the latter half alone at .791 still. The 2.3 exterior sidewall of the crank interior that shaft goes into is only approx .837. So i'f I put the pilot bearing on the .59 surface into the .827 sidewill the tip is OK, but the rest of the shaft at .791 in a .827 hole leaves only a .036 amount of clearance!

Is this something that I need milled down to .59 or does it even matter?

For any of you 2.3 guys that have done an upgrade T5 swap from the questionable 4cyl box to the V8, how far have you milled the input shaft?

The shaft I had taken to a local machine shop wasn't milled all the way to the shaft teeth. It's basically tapered on the pilot bearing tip. If you can imagine what a stock V8 shaft tip looks like, the larger inner surface should be something like .791 and the end a .668. I had the end milled to .59 but the shop left the latter half alone at .791 still. The 2.3 exterior sidewall of the crank interior that shaft goes into is only approx .837. So i'f I put the pilot bearing on the .59 surface into the .827 sidewill the tip is OK, but the rest of the shaft at .791 in a .827 hole leaves only a .036 amount of clearance!

Is this something that I need milled down to .59 or does it even matter?