the only reason, only reason why i want to sort of wait is because im not totally sure if i just want to do a 306 maybe with or without a supercharger or either a 331 with or without an SC. Truth is financially right now i dont want to get the SC though I can but a new truck is in store for me before yr is out or by end of the yr and it aint going to be cheap for what i want. So at the least i will get the head back and do a leak down test on the no. 2 cylinder, or better yet the whole side while I'm at it. I was hoping to just get the thing back together, not having spend much money and doing all labor myself minus the heads, and then taking my time and planning my next build. That's providing the leak down test shows good . Also i rubbed my finger over the whole area and didnt feel any gasket material or anything. It appears there is some on there but i've learned over the years of cleaning up the areas of any gasket surface of anything that as old as the metal is, there appears to be some gasket that has embedded into the metal and if you take a razor blade and try and dig in, you will actually dig into the metal and it leave unevenness and scratching. resultsI agree.

There is no way id get that close to the bottom end without pulling it apart for a fresh set of bearings and the works, unless the motor was already recently freshend up.

However, that piston scrub probably won't kill a deal if you just want to throw it back together...

what do you mean won't kill a deal?

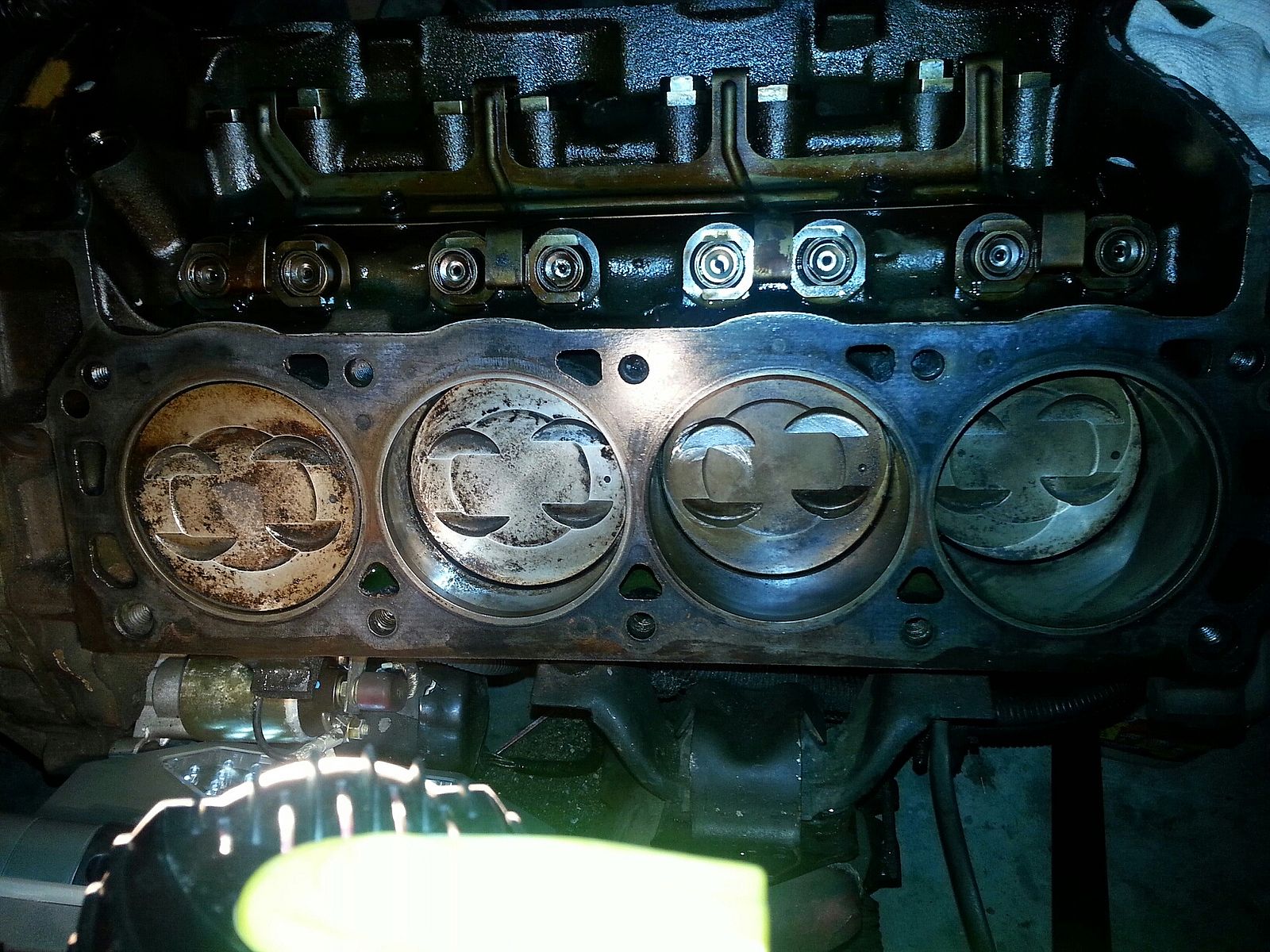

and while im at it i might as well post images of the one side i just cleaned and to see what you guys think if its fine or not. Just used elbow grease and laquer thinner, carb cleaner, and some foam action cleaner. Damn carbon on the pistons seemed as good as i could get it.