Just had a 1990 coupe that quit running. Was losing ground to the injectors. Switched in my EEC IV to verify and car started. When I put EEC IV back into the 1993 Hatch ,the check engine light stays on. Have tried to clear with no success. Fault codes 23,34,22,35,51,53 & 54 show up during KOEO test. Any suggestions would help. Thanks for any info.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Check engine light on after EEC IV switch

- Thread starter shockertech

- Start date

-

Sponsors (?)

Check that the TPS signal isn't shorted to VREF or otherwise out of spec. If the EEC sees more than 2.71V above the TPS baseline (generally about 1.0 V), it considers that to be WOT, and while cranking at such voltage, the injectors are shut off via removal of the modulated ground.

Did the EEC generate all those codes before you removed the EEC? If not, go over all the things you touched, esp the wiring harness at the EEC.

Good luck.

Did the EEC generate all those codes before you removed the EEC? If not, go over all the things you touched, esp the wiring harness at the EEC.

Good luck.

Checked tps voltage late last night and it showed no voltage. I will recheck tommorrow and repull the EEC and check the connections. I will update if I find anything.

Checked tps voltage late last night and it showed no voltage. I will recheck tommorrow and repull the EEC and check the connections. I will update if I find anything.

I forgot to say welcome to the forums!

Recheck the TPS, as it should not show zero volts KOEO.

As with all checklist procedures, start at the top and work your way down. Do not skip any steps as the results of the next test depend on the last test having completed satisfactorily.

As with all checklist procedures, start at the top and work your way down. Do not skip any steps, as the results of the next test depend on the last test having completed satisfactorily

Theory of how it works:

The computer supplies 5 volt VREF to power 3 sensors. They are the TPS, EGR and MAP/BARO sensors. The use of a tightly regulated voltage insures that all sensors are accurate over a wide range of operating temperatures. Note that the VREF orange/white wire supplies two engine mounted sensors (TPS & EGR) and one firewall mounted sensor (MAP/BARO sensor). VREF also powers all the electronics inside the computer.

Tools needed:

DVM with good batteries. Know the difference between voltage (volts) and resistance (ohms) and how to measure them with your DVM. Make sure you know how to read voltages and resistances with you meter. Some DVM’s auto range and others require you to select the range. Be sure you understand the range selection process if your DVM does not auto range. Do not touch the probe tips while making resistance measurements. If you do, your measurements will be very wrong.

Two or three big safety pins. You may need them to probe the electrical connector plugs from the rear. Keep in mind that it may require some effort to make good connections to use your DVM. Flaky or intermittent connections can lead you down the wrong path.

#2 Philips screwdriver

¼” flat blade screwdriver.

5/16” socket

¼ drive ratchet

3” long 1/4 “ extension.

3/8” ratchet

10 MM deep socket or 10 mm socket & 3” extension.

Getting started:

Verify that VREF is good:

1.) The fist step is to dump the codes: if one of the sensors is shorting VREF to ground, you will get codes 22 (MAP/BARO sensor), 63 (TPS sensor), and 31 or 32 (EGR sensor). You will get all the codes if VREF is shorted to ground, not just one or two of them.

2.) The next step is to determine which sensor is causing the low VREF voltage.

A.) All sensors connected and installed correctly. Ignition off:

Locate the MAP/BARO sensor on the firewall behind the upper intake manifold. Insert one safety pin in the rear of the electrical connector where the black/white wire is connected. Insert another safety pin in the rear of the electrical connector where the orange/white wire is connected. Make sure the safety pins do not touch each other or metal parts of the body or engine. Connect the DVM or meter to the safety pins. If your meter is polarity sensitive, be sure that it is connected correctly: positive to the orange/white wire, negative to the black/white wire.

B.) Turn the ignition switch to Run, but do not start the engine. Note the voltage: it should be between 4.5 and 5.5 volts. If it is within range, go to step 5. If it is over 5.5 volts, go to step 7

C.) If the voltage is less that 1 volt, turn off the ignition switch and ground the DVM or meter negative lead to the battery post. Turn the ignition switch to the Run position but do not start the engine. Recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the signal ground to the MAP/BARO sensor is bad.

D.) If the voltage is still below 4.5 volts, turn off the ignition switch and disconnect the electrical connector from the MAP/BARO sensor. Turn the ignition switch to the Run position but do not start the engine and recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the MAP/BARO sensor is bad. Time to replace the sensor. You will find that you will get a code 22 if the MAP/BARO sensor is bad. Leave the MAP/BARO sensor disconnected until the other sensors have been tested.

3.) TPS sensor connected and installed correctly. Ignition off:

The TPS is mounted on the top side of the throttle body. Insert one safety pin in the rear of the electrical connector where the black/white wire is connected. Insert another safety pin in the rear of the electrical connector where the orange/white wire is connected. Make sure the safety pins do not touch each other or metal parts of the body or engine. Connect the DVM or meter to the safety pins. If your meter is polarity sensitive, be sure that it is connected correctly: positive to the orange/white wire, negative to the black/white wire

A.) Turn the ignition switch to Run, but do not start the engine. Note the voltage: it should be between 4.5 and 5.5 volts. If it is within range, go to step 4 to check VREF on the EGR sensor.

B.) If the voltage is less that 1 volt, turn off the ignition switch and ground the DVM or meter negative lead to the battery post. Turn the ignition switch to the Run position but do not start the engine and recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the signal ground to the TPS sensor is bad.

C.) If the voltage is still below 4.5 volts, turn off the ignition switch and disconnect the electrical connector from the TPS sensor. Turn the ignition switch to the Run position but do not start the engine. Recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the TPS sensor is bad. Time to replace the sensor.

D.) If the voltage is still below 4.5 volts, Leave the TPS sensor disconnected until the other sensors have been tested. Then go to step 4

4.) EGR sensor connected and installed correctly. Ignition off:

The EGR is mounted on the back side of the EGR valve. Insert one safety pin in the rear of the electrical connector where the black/white wire is connected. Insert another safety pin in the rear of the electrical connector where the orange/white wire is connected. Make sure the safety pins do not touch each other or metal parts of the body or engine. Connect the DVM or meter to the safety pins. If your meter is polarity sensitive, be sure that it is connected correctly: positive to the orange/white wire, negative to the black/white wire

A.) Turn the ignition switch to Run, but do not start the engine. Note the voltage: it should be between 4.5 and 5.5 volts. If it is within range, go to step 5.

B.) If the voltage is less that 1 volt, turn off the ignition switch and ground the DVM or meter negative lead to the battery post. Turn the ignition switch to the Run position but do not start the engine and recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the signal ground to the EGR sensor is bad.

C.) If the voltage is still below 4.5 volts, turn off the ignition switch and disconnect the electrical connector from the EGR sensor. Turn the ignition switch to the Run position but do not start the engine. Recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the EGR sensor is bad. Time to replace the sensor.

D.) If the voltage is still below 4.5 volts, go to step 5 to check for wiring faults.

5.) VREF less that 4.5 volts with all sensors disconnected:

Disconnect the battery negative cable at the battery. Remove the passenger side kick panel and then loosen the 10 MM hex bolt that secures the computer wiring harness connector to the computer. Measure the resistance between pin 26 on the computer and the orange/white wires on the MAP/BARO, TPS and EGR sensors. You should see less that 1.5 ohms on each of the orange/white wires and pin 26. More than that indicates wiring problem.

Computer wiring harness connecter as viewed from the pin side.

The 10 pin connectors that join the engine fuel injector harness to the main harness are prime suspects.

Notice that pin 1 on the black connector is VREF. If this pin has a bad connection or broken wire, both the TPS and EGR will have no or low VREF voltage. A high resistance on only one wire is an indication of a broken wire or bad connection inside the fuel injector wiring harness.

If the above resistance test passes, move the meter lead from pin 26 to the ground point next to the computer. Then measure the resistance between the orange/white wire on any of the sensors and ground. You should see greater than 1 Megohm or an infinite open circuit. Reconnect the sensors and the computer, reconnect the battery negative cable to the battery.

6.) At this point, you have verified that all the sensors that use VREF have the proper supply voltage. If you still do not have proper VREF, then the problem is inside the computer. This is a replace the computer with a known good unit and retest to see if you get the same codes 22 (MAP/BARO sensor), 63 (TPS sensor), and 31 or 32 (EGR sensor). All the codes should have cleared unless you have some faulty sensors.

7.) VREF exceeds 5.5 volts:

Disconnect the battery negative cable at the battery. Remove the passenger side kick panel and then loosen the 10 MM hex bolt that secures the computer wiring harness connector to the computer. Pull the wiring harness connector down so that it disconnects from the computer. Then measure the resistance between the orange/white wire on any of the sensors and pin 1. Then measure the resistance between the orange/white wire on any of the sensors and pin 37. You should see greater than 1 Megohm or an infinite open circuit in both cases. Less than 1 Megohm indicates a wiring problem.

If the resistance check is good, then the problem is inside the computer. This is a replace the computer with a known good unit and retest to see if you get the same high voltage readings. If you do, then your DVM may be whacko…

VREF is verified as good, sensor output is still low:

8.) One or more sensors get a low output voltage code (63 - TPS sensor, or 31 or 32 - EGR sensor). After you have replaced the sensor and are still getting a low voltage code or low voltage reading, it is time to go hunting. By completing steps 1-7, you have verified that you have good VREF and it is not a cause of your problem.

Disconnect the battery negative cable at the battery. Remove the passenger side kick panel and then loosen the 10 MM hex bolt that secures the computer wiring harness connector to the computer. Pull the wiring harness connector down so that it disconnects from the computer.

Make sure that the TPS & EGR sensors are disconnected while performing the following tests. If you don't disconnect them, you will get incorrect measurements.

A.) TPS sensor: measure the resistance between the TPS green/lt green wire and pin 47. You should see less than 1.5 ohms. More than that indicates a wiring problem. Then measure the resistance between the green/lt green wire on the TPS sensor and ground. You should see greater than 1 Megohm or an infinite open circuit.

Adjust the TPS sensor as follows:

Set the TPS voltage at .5- 1.1 range. Because of the variables involved with the tolerances of both computer and DVM, I would shoot for somewhere between .6 and 1.0 volts. Unless you have a Fluke or other high grade DVM, the second digit past the decimal point on cheap DVM’s is probably fantasy. Since the computer zeros out the TPS voltage every time it powers up, playing with the settings isn't an effective aid to performance or drivability. The main purpose of checking the TPS is to make sure it isn't way out of range and causing problems. Put the safety pins in the Dark Green/Lt green wire and Black/White wire. Make sure the ignition switch is in the Run position but the engine isn't running.

B.) EGR sensor: measure the resistance between the EGR brown/lt green wire and pin 27. You should see less than 1.5 ohms. More than that indicates a wiring problem. Then measure the resistance between the brown /lt green wire on the EGR sensor and ground. You should see greater than 1 Megohm or an infinite open circuit.

C.) If both the above tests pass, then the problem is inside the computer. This is a replace the computer with a known good unit and retest to see if you get the same low voltage readings. If you do, then your DVM may be whacko…

As with all checklist procedures, start at the top and work your way down. Do not skip any steps, as the results of the next test depend on the last test having completed satisfactorily

Theory of how it works:

The computer supplies 5 volt VREF to power 3 sensors. They are the TPS, EGR and MAP/BARO sensors. The use of a tightly regulated voltage insures that all sensors are accurate over a wide range of operating temperatures. Note that the VREF orange/white wire supplies two engine mounted sensors (TPS & EGR) and one firewall mounted sensor (MAP/BARO sensor). VREF also powers all the electronics inside the computer.

Tools needed:

DVM with good batteries. Know the difference between voltage (volts) and resistance (ohms) and how to measure them with your DVM. Make sure you know how to read voltages and resistances with you meter. Some DVM’s auto range and others require you to select the range. Be sure you understand the range selection process if your DVM does not auto range. Do not touch the probe tips while making resistance measurements. If you do, your measurements will be very wrong.

Two or three big safety pins. You may need them to probe the electrical connector plugs from the rear. Keep in mind that it may require some effort to make good connections to use your DVM. Flaky or intermittent connections can lead you down the wrong path.

#2 Philips screwdriver

¼” flat blade screwdriver.

5/16” socket

¼ drive ratchet

3” long 1/4 “ extension.

3/8” ratchet

10 MM deep socket or 10 mm socket & 3” extension.

Getting started:

Verify that VREF is good:

1.) The fist step is to dump the codes: if one of the sensors is shorting VREF to ground, you will get codes 22 (MAP/BARO sensor), 63 (TPS sensor), and 31 or 32 (EGR sensor). You will get all the codes if VREF is shorted to ground, not just one or two of them.

2.) The next step is to determine which sensor is causing the low VREF voltage.

A.) All sensors connected and installed correctly. Ignition off:

Locate the MAP/BARO sensor on the firewall behind the upper intake manifold. Insert one safety pin in the rear of the electrical connector where the black/white wire is connected. Insert another safety pin in the rear of the electrical connector where the orange/white wire is connected. Make sure the safety pins do not touch each other or metal parts of the body or engine. Connect the DVM or meter to the safety pins. If your meter is polarity sensitive, be sure that it is connected correctly: positive to the orange/white wire, negative to the black/white wire.

B.) Turn the ignition switch to Run, but do not start the engine. Note the voltage: it should be between 4.5 and 5.5 volts. If it is within range, go to step 5. If it is over 5.5 volts, go to step 7

C.) If the voltage is less that 1 volt, turn off the ignition switch and ground the DVM or meter negative lead to the battery post. Turn the ignition switch to the Run position but do not start the engine. Recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the signal ground to the MAP/BARO sensor is bad.

D.) If the voltage is still below 4.5 volts, turn off the ignition switch and disconnect the electrical connector from the MAP/BARO sensor. Turn the ignition switch to the Run position but do not start the engine and recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the MAP/BARO sensor is bad. Time to replace the sensor. You will find that you will get a code 22 if the MAP/BARO sensor is bad. Leave the MAP/BARO sensor disconnected until the other sensors have been tested.

3.) TPS sensor connected and installed correctly. Ignition off:

The TPS is mounted on the top side of the throttle body. Insert one safety pin in the rear of the electrical connector where the black/white wire is connected. Insert another safety pin in the rear of the electrical connector where the orange/white wire is connected. Make sure the safety pins do not touch each other or metal parts of the body or engine. Connect the DVM or meter to the safety pins. If your meter is polarity sensitive, be sure that it is connected correctly: positive to the orange/white wire, negative to the black/white wire

A.) Turn the ignition switch to Run, but do not start the engine. Note the voltage: it should be between 4.5 and 5.5 volts. If it is within range, go to step 4 to check VREF on the EGR sensor.

B.) If the voltage is less that 1 volt, turn off the ignition switch and ground the DVM or meter negative lead to the battery post. Turn the ignition switch to the Run position but do not start the engine and recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the signal ground to the TPS sensor is bad.

C.) If the voltage is still below 4.5 volts, turn off the ignition switch and disconnect the electrical connector from the TPS sensor. Turn the ignition switch to the Run position but do not start the engine. Recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the TPS sensor is bad. Time to replace the sensor.

D.) If the voltage is still below 4.5 volts, Leave the TPS sensor disconnected until the other sensors have been tested. Then go to step 4

4.) EGR sensor connected and installed correctly. Ignition off:

The EGR is mounted on the back side of the EGR valve. Insert one safety pin in the rear of the electrical connector where the black/white wire is connected. Insert another safety pin in the rear of the electrical connector where the orange/white wire is connected. Make sure the safety pins do not touch each other or metal parts of the body or engine. Connect the DVM or meter to the safety pins. If your meter is polarity sensitive, be sure that it is connected correctly: positive to the orange/white wire, negative to the black/white wire

A.) Turn the ignition switch to Run, but do not start the engine. Note the voltage: it should be between 4.5 and 5.5 volts. If it is within range, go to step 5.

B.) If the voltage is less that 1 volt, turn off the ignition switch and ground the DVM or meter negative lead to the battery post. Turn the ignition switch to the Run position but do not start the engine and recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the signal ground to the EGR sensor is bad.

C.) If the voltage is still below 4.5 volts, turn off the ignition switch and disconnect the electrical connector from the EGR sensor. Turn the ignition switch to the Run position but do not start the engine. Recheck the voltage readings. If the voltage reads 4.5 to 5.5 volts, the VREF is good and the EGR sensor is bad. Time to replace the sensor.

D.) If the voltage is still below 4.5 volts, go to step 5 to check for wiring faults.

5.) VREF less that 4.5 volts with all sensors disconnected:

Disconnect the battery negative cable at the battery. Remove the passenger side kick panel and then loosen the 10 MM hex bolt that secures the computer wiring harness connector to the computer. Measure the resistance between pin 26 on the computer and the orange/white wires on the MAP/BARO, TPS and EGR sensors. You should see less that 1.5 ohms on each of the orange/white wires and pin 26. More than that indicates wiring problem.

Computer wiring harness connecter as viewed from the pin side.

The 10 pin connectors that join the engine fuel injector harness to the main harness are prime suspects.

Notice that pin 1 on the black connector is VREF. If this pin has a bad connection or broken wire, both the TPS and EGR will have no or low VREF voltage. A high resistance on only one wire is an indication of a broken wire or bad connection inside the fuel injector wiring harness.

If the above resistance test passes, move the meter lead from pin 26 to the ground point next to the computer. Then measure the resistance between the orange/white wire on any of the sensors and ground. You should see greater than 1 Megohm or an infinite open circuit. Reconnect the sensors and the computer, reconnect the battery negative cable to the battery.

6.) At this point, you have verified that all the sensors that use VREF have the proper supply voltage. If you still do not have proper VREF, then the problem is inside the computer. This is a replace the computer with a known good unit and retest to see if you get the same codes 22 (MAP/BARO sensor), 63 (TPS sensor), and 31 or 32 (EGR sensor). All the codes should have cleared unless you have some faulty sensors.

7.) VREF exceeds 5.5 volts:

Disconnect the battery negative cable at the battery. Remove the passenger side kick panel and then loosen the 10 MM hex bolt that secures the computer wiring harness connector to the computer. Pull the wiring harness connector down so that it disconnects from the computer. Then measure the resistance between the orange/white wire on any of the sensors and pin 1. Then measure the resistance between the orange/white wire on any of the sensors and pin 37. You should see greater than 1 Megohm or an infinite open circuit in both cases. Less than 1 Megohm indicates a wiring problem.

If the resistance check is good, then the problem is inside the computer. This is a replace the computer with a known good unit and retest to see if you get the same high voltage readings. If you do, then your DVM may be whacko…

VREF is verified as good, sensor output is still low:

8.) One or more sensors get a low output voltage code (63 - TPS sensor, or 31 or 32 - EGR sensor). After you have replaced the sensor and are still getting a low voltage code or low voltage reading, it is time to go hunting. By completing steps 1-7, you have verified that you have good VREF and it is not a cause of your problem.

Disconnect the battery negative cable at the battery. Remove the passenger side kick panel and then loosen the 10 MM hex bolt that secures the computer wiring harness connector to the computer. Pull the wiring harness connector down so that it disconnects from the computer.

Make sure that the TPS & EGR sensors are disconnected while performing the following tests. If you don't disconnect them, you will get incorrect measurements.

A.) TPS sensor: measure the resistance between the TPS green/lt green wire and pin 47. You should see less than 1.5 ohms. More than that indicates a wiring problem. Then measure the resistance between the green/lt green wire on the TPS sensor and ground. You should see greater than 1 Megohm or an infinite open circuit.

Adjust the TPS sensor as follows:

Set the TPS voltage at .5- 1.1 range. Because of the variables involved with the tolerances of both computer and DVM, I would shoot for somewhere between .6 and 1.0 volts. Unless you have a Fluke or other high grade DVM, the second digit past the decimal point on cheap DVM’s is probably fantasy. Since the computer zeros out the TPS voltage every time it powers up, playing with the settings isn't an effective aid to performance or drivability. The main purpose of checking the TPS is to make sure it isn't way out of range and causing problems. Put the safety pins in the Dark Green/Lt green wire and Black/White wire. Make sure the ignition switch is in the Run position but the engine isn't running.

B.) EGR sensor: measure the resistance between the EGR brown/lt green wire and pin 27. You should see less than 1.5 ohms. More than that indicates a wiring problem. Then measure the resistance between the brown /lt green wire on the EGR sensor and ground. You should see greater than 1 Megohm or an infinite open circuit.

C.) If both the above tests pass, then the problem is inside the computer. This is a replace the computer with a known good unit and retest to see if you get the same low voltage readings. If you do, then your DVM may be whacko…

Thanks for all the information and tests. I will perform all these checks later today and report back with any findings. Thanks again!

Started checking vref. Found 0volts at all 3 sensors using the sensor ground wire. Using negative post for ground I have 5 Volts at each sensor verifying that the ground is bad. Checked resistance between pin 26 and orange/white wire as suggessted. All three show .5 ohms, good. Checked between ground right below EEC and all three show 0.L ohms, good. On the car i swapped the computer into, this ground was torn loose and not connected. When I switched the EEC in, it was not connected. Is it possible that this burnt the ground circuit in side the computer. Maybe this was my original problem with the injectors on the other car. I fixed the ground before I installed the new EEC. It seems i have a bad EEC and need to replace before doing any other checks. Thanks for any input.

joel5.0

New Member

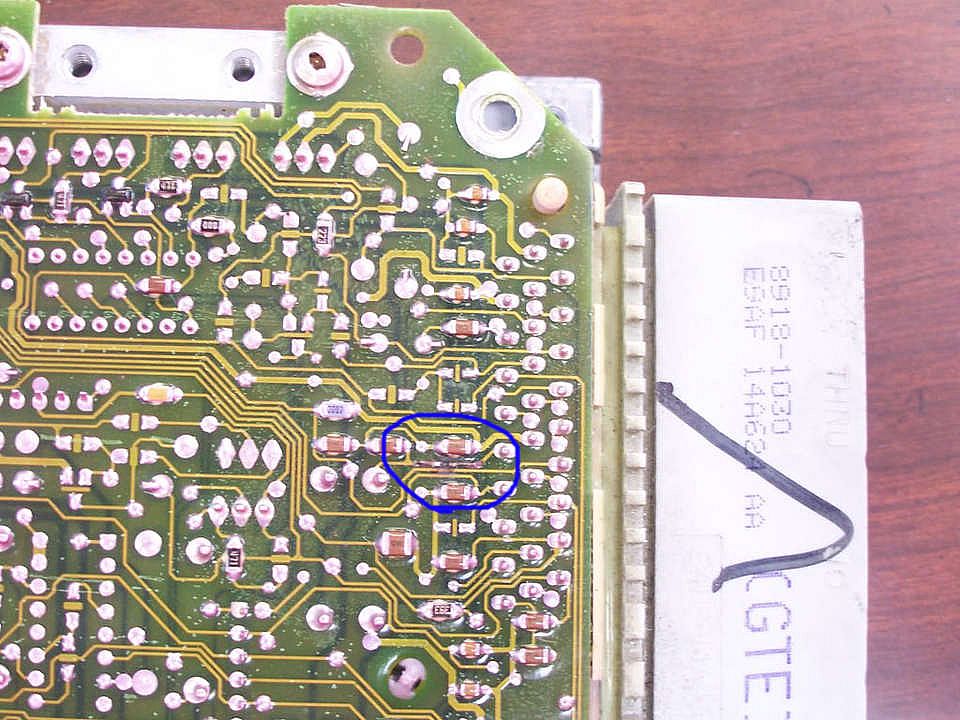

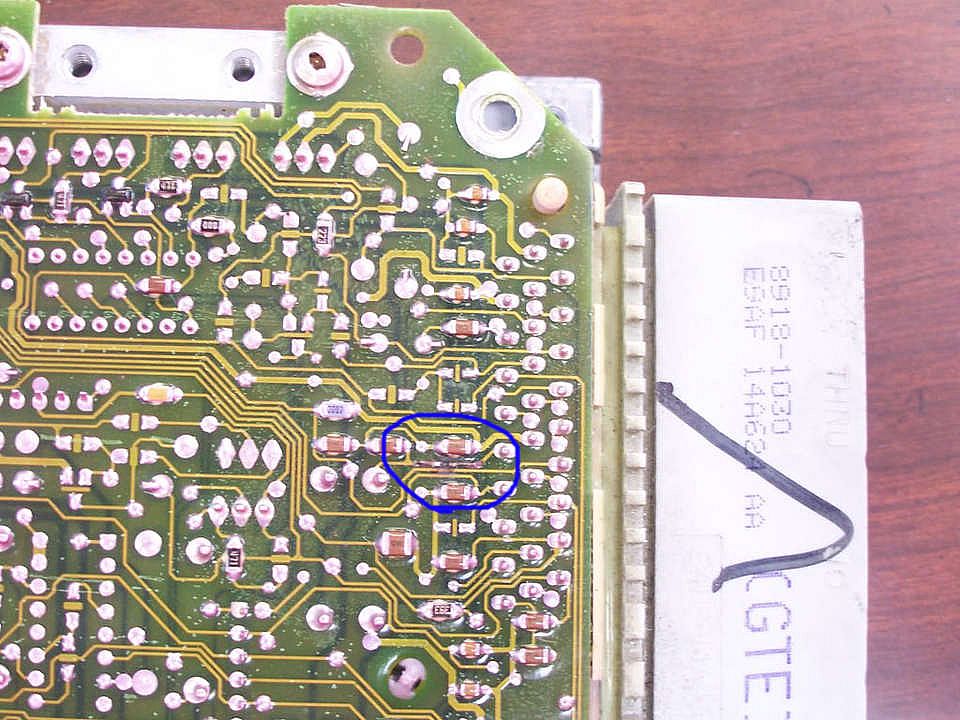

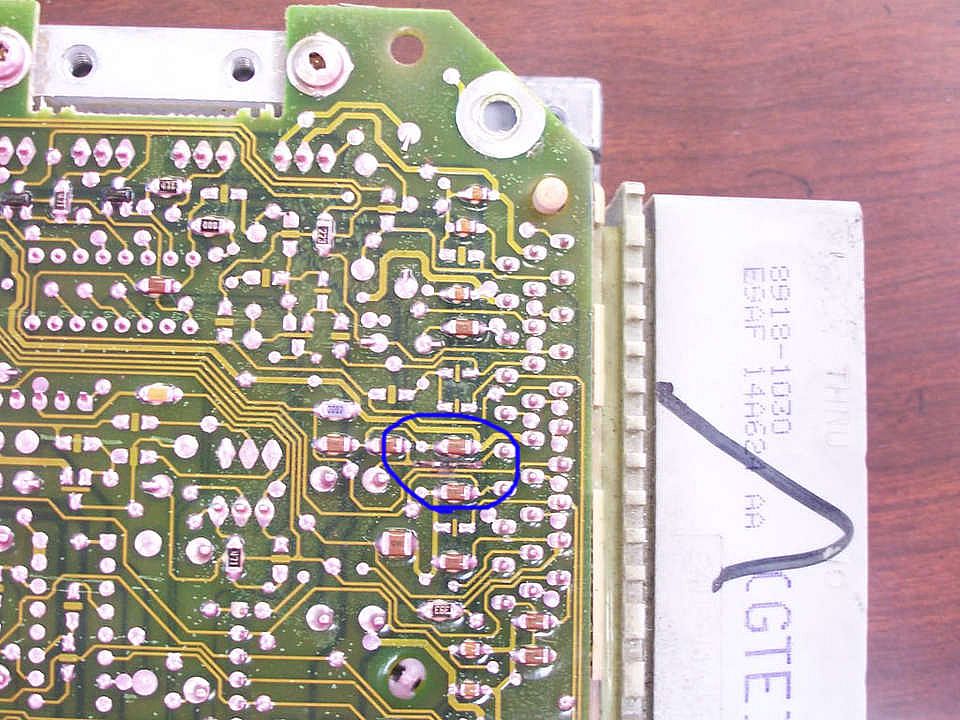

Open that ECM and check for the following........

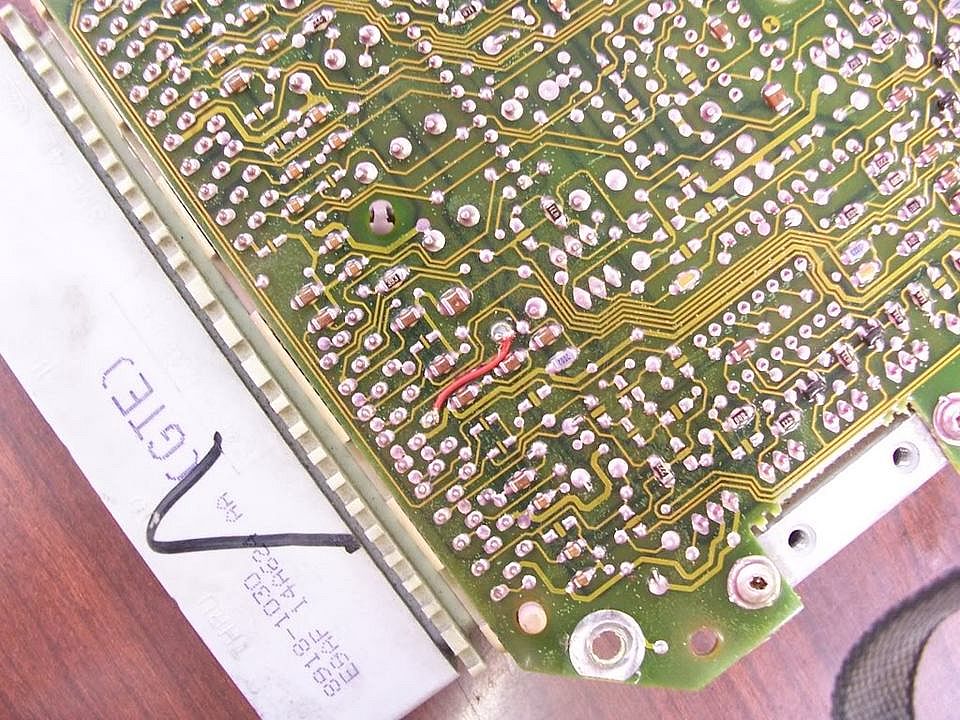

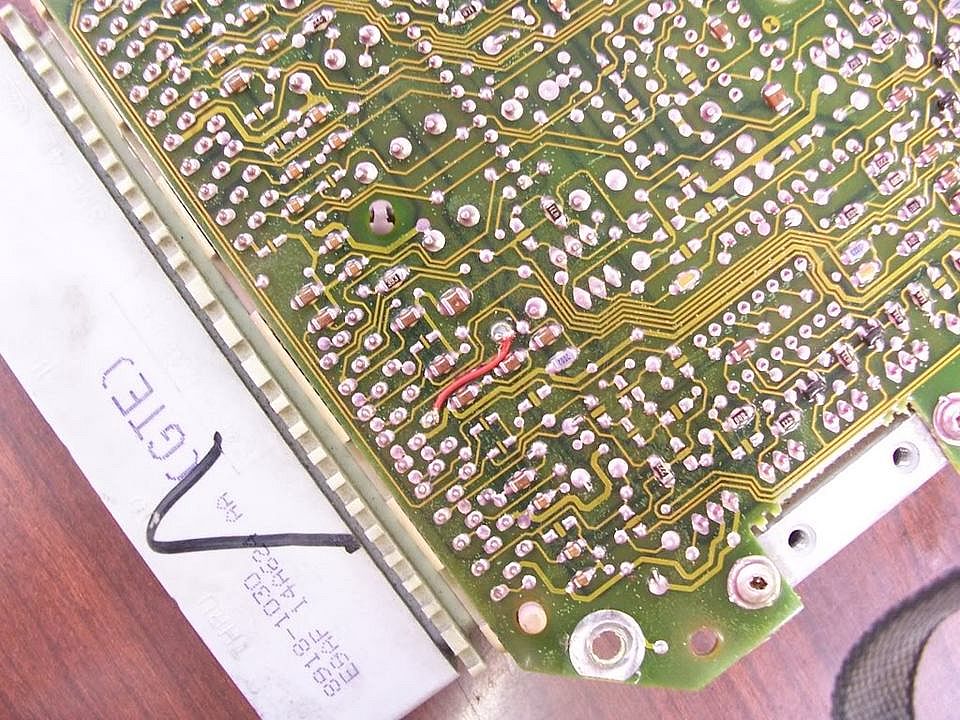

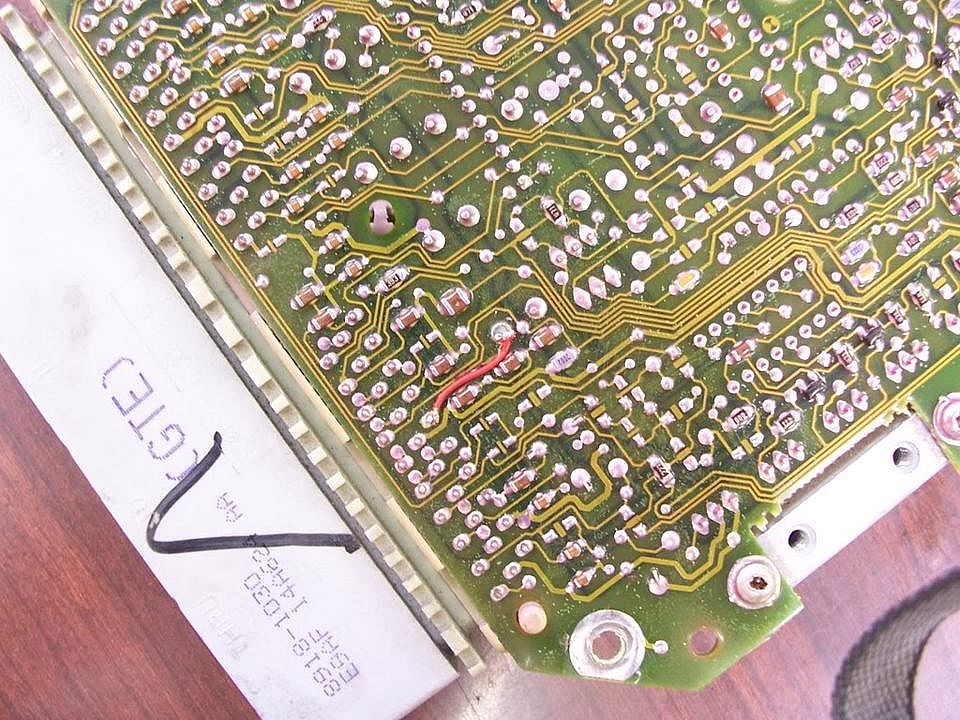

If the above is the case, all you need is a soldering iron + solder + piece of wire to fix it like.....

Just make sure that before you install it, 12vdc doesn't show up in a DVOM voltage check at pin 46, with key in IGN ON and when you crank the engine... with the ECM disconnected. LUK

If the above is the case, all you need is a soldering iron + solder + piece of wire to fix it like.....

Just make sure that before you install it, 12vdc doesn't show up in a DVOM voltage check at pin 46, with key in IGN ON and when you crank the engine... with the ECM disconnected. LUK

Attachments

Open that ECM and check for the following........

If the above is the case, all you need is a soldering iron + solder + piece of wire to fix it like.....

Just make sure that before you install it, 12vdc doesn't show up in a DVOM voltage check at pin 46, with key in IGN ON and when you crank the engine... with the ECM disconnected. LUK

Yes that will work...

But considering the electrical and soldering talents I have seen here on Stangnet, there are only a small handful of people that could do it and get it right.

What usually burns the trace off the computer PC board is when people jumper the wrong connection to dump the codes or connect a scanner.

The correct wire has a gray connector shell and a white/red wire. It comes from the same bundle of wires as the self test connector.

The wrong wire has a dark brown connector with a black/orange wire. It is the 12 volt power to the under the hood light. Jumpering it to the test connector results in dead power to ground short. That burns the trace off the computer's PC board. Then you can't dump codes and the MAP, TPS, EGR ECT & ACT sensors lose their ground and give incorrect data to the computer.

One thing to keep in mind:if you can dump codes, the signal ground inside the computer is OK.

Attachments

Finally got a chance to open up the EEC and the circuit was damaged. Resoldered a piece of wire and jackpot, the problem is fixed. I really appreciate the help you guys gave. Again, Thanks for all the great input.

i know this is old but i wanted to say thank you to jrichker for his thorough write up, i followed it step by step and found the trace to be bad in my ecu. whipped out the soldering iron, tacked a new wire into place and the car fired right up and idled.

dave

dave

Hey that looks familiar!Open that ECM and check for the following........

If the above is the case, all you need is a soldering iron + solder + piece of wire to fix it like.....

I do have good soldering skills, don't I?

Similar threads

- Replies

- 26

- Views

- 2K

- Replies

- 6

- Views

- 566

Electrical

Wiring Struggles!

- Replies

- 6

- Views

- 982

- Replies

- 8

- Views

- 2K

- Replies

- 4

- Views

- 1K