Does anyone have an economical trigger wheel setup with crank sensor bracket they can share.

I've seen a few with the trigger wheel mounted between the balancer and the pulley. Did this cause any alignment issues with the belt system?

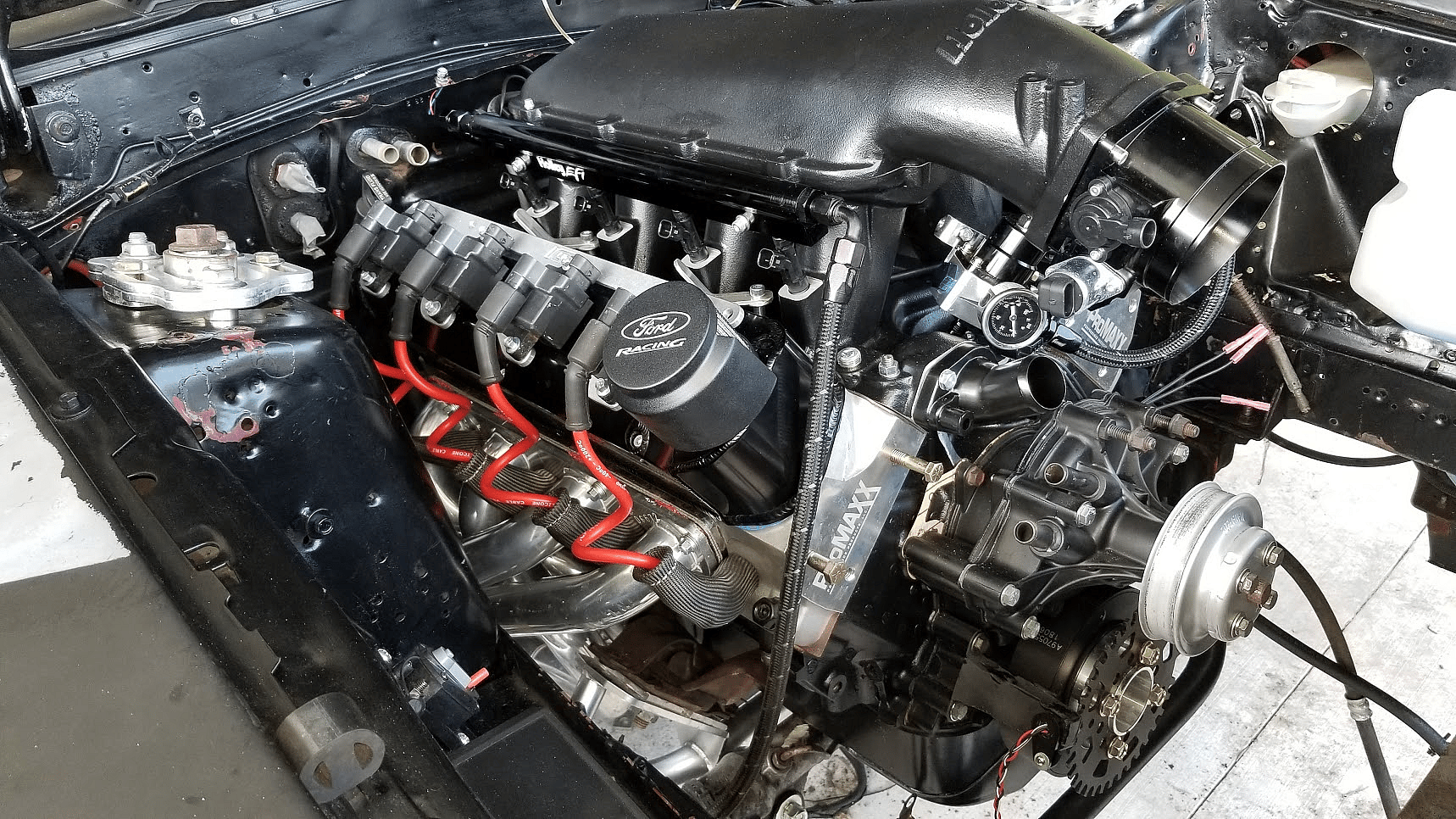

What I'm looking at so far.

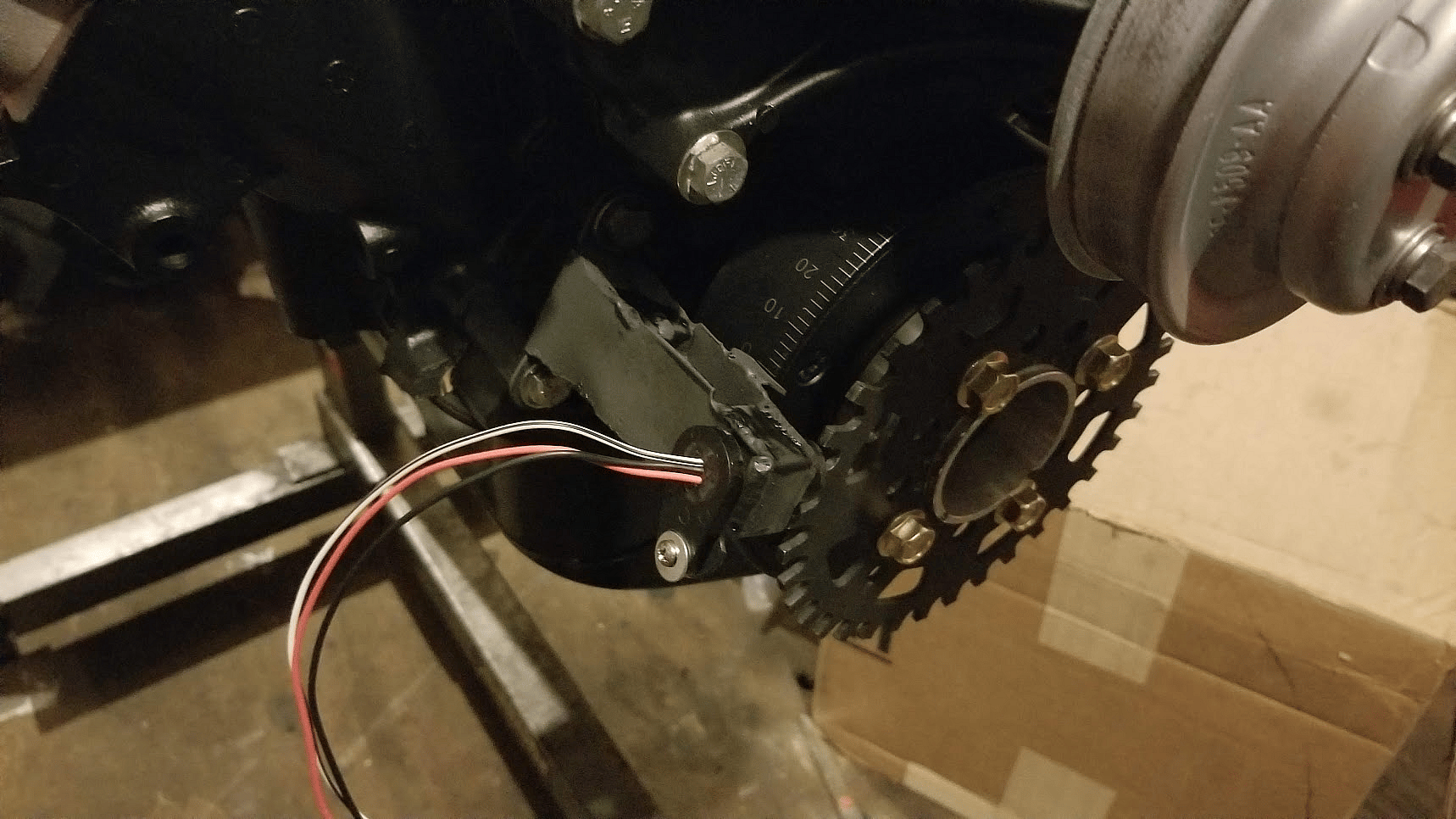

DIY Wheel

Escort sensor

I've seen a few with the trigger wheel mounted between the balancer and the pulley. Did this cause any alignment issues with the belt system?

What I'm looking at so far.

DIY Wheel

Escort sensor