- Mar 7, 2002

- 9,436

- 5,384

- 224

DRiV | Quality Auto Parts

Count on DRiV for auto parts that deliver the quality, safety and performance you demand.

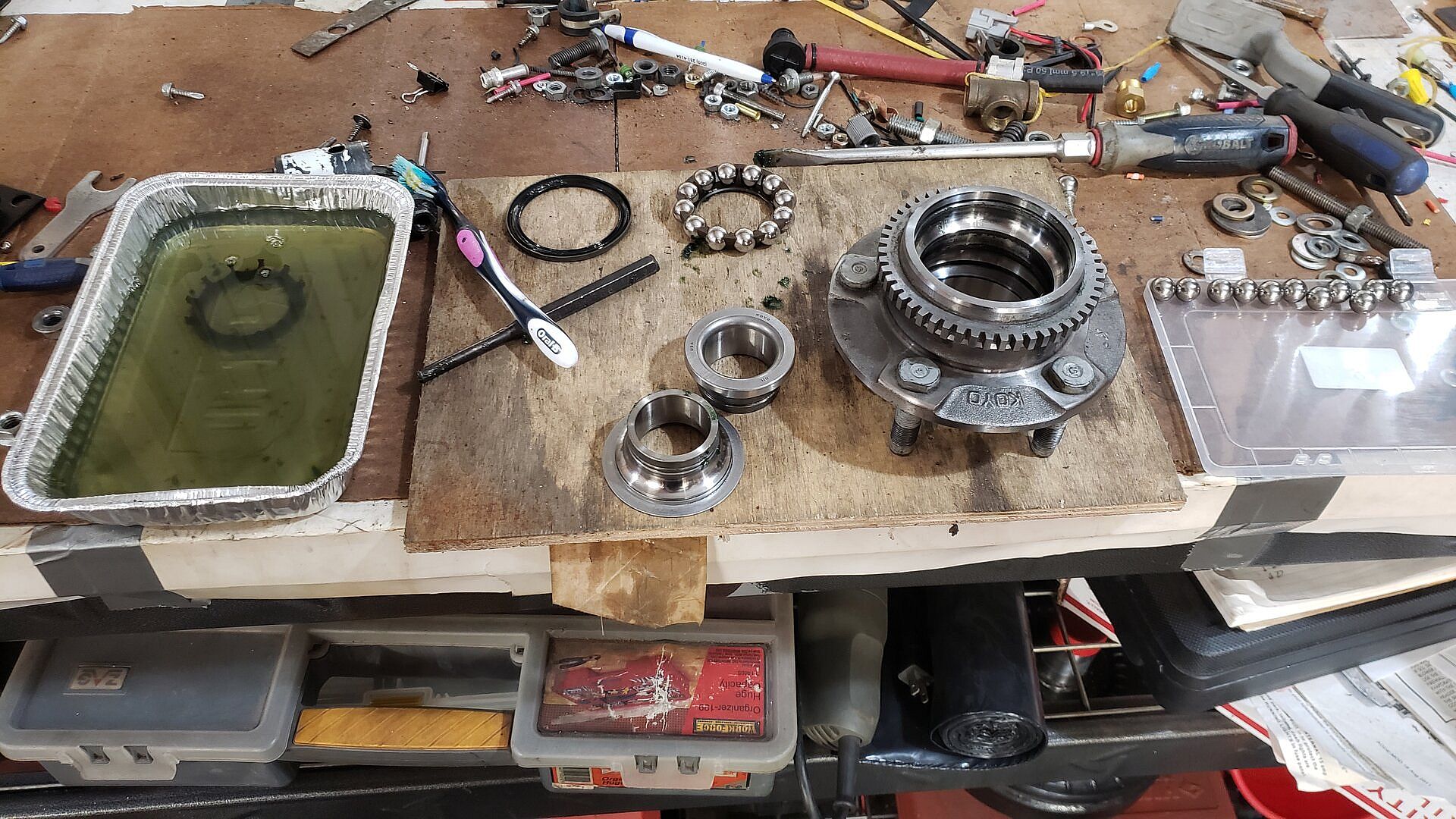

Try the Moog hub assembly (part number at link above). I've installed dozens of those over the years, including on my GMC pickup when I had it and my mother's Taurus. For some reason they're the ONLY hub assemblies I haven't had problems with.

Moog can't make a damned tie rod end to save their lives, but they make one hell of a hub assembly. Timken used to be the

, now they are

, now they are  .

.