I don't understand how an adjustable guide plate is gonna quieten down mechanical valve train noise?With all this talk of big pressure numbers from the M112 and my goals to achieve that end, we breezed past some issues that need to be addressed. The main issue in my mind is the valve train noise, the last thing i need is to bend break or bind something while i am 100 miles from the house...

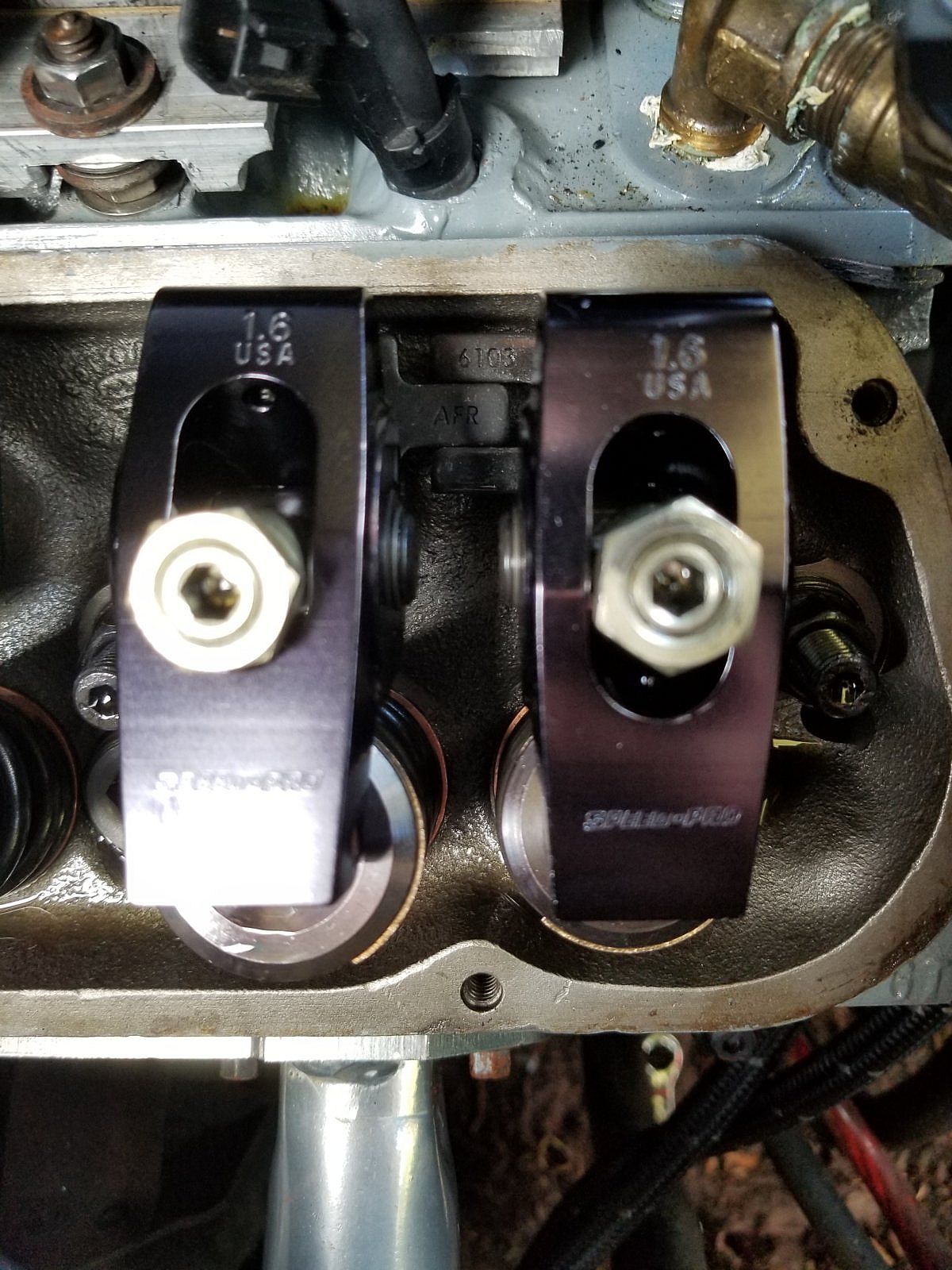

So to remedy that i bought some AFR adjustable guide plates to install today. I sure hope this fixes the noisiness it is driving me crazy! Of course i will snap some pics along the way.

I also got some plug wire terminals and boots to cut the existing wires to length, I am going to use the yellow wires i got from weapon-x.... not my first choice in color but they will have to do for now. maybe i can hide them with wire loom.... lol

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread Enola- Finishing touches

- Thread starter a91what

- Start date

-

Sponsors (?)

Same guide plates I used on the last build, they have a ton of slop between the pushrod and the guide. Allowing the rod and rocker to move around on the valve stem. This totallyI don't understand how an adjustable guide plate is gonna quieten down mechanical valve train noise?

s the geometry as they move around, this is an attempt to fix my own mistake.

s the geometry as they move around, this is an attempt to fix my own mistake.That's an interesting point. Complaints about roller rocker noise seem to be very common around here; maybe you have found the fix for a common problem...Same guide plates I used on the last build, they have a ton of slop between the pushrod and the guide. Allowing the rod and rocker to move around on the valve stem. This totally ****s the geometry as they move around, this is an attempt to fix my own mistake.

I sure hope so J.That's an interesting point. Complaints about roller rocker noise seem to be very common around here; maybe you have found the fix for a common problem...

Found a problem.... I pulled the plugs and #4 is near fouled... #8 is slightly darker than the front 6. Only thing I can think of is the fact these injectors sit directly under the coil packs, I am going to create a shield on the injectors back there with tin foil. This will at least rule the coils out as interference, I am also swapping the coils and plug wires to rule out weak spark. If a new plug in that hole fouls again I will be forced to assume it's a bad/leaky injector.

The front 6 plugs look perfect, I may have to try something different... like using a plug slightly hotter in those two holes.

The front 6 plugs look perfect, I may have to try something different... like using a plug slightly hotter in those two holes.

Steel1

Mustang Master

So you're thinking the coil packs could be causing some electrical interference with the injectors ?

Will be interesting to see what results you get, would be nice if that's it and a simple shield would solve the problem.

As an aside are you sure push rod length is correct ?

When I built my 393w I had a very noisy rocker issue, long story short I ended up using the "Straub" method to measure

push rods, ordered revised length which greatly reduced the noise.

It's been my experience that these roller set ups tend to be a little noisy even when properly adjusted.

Will be interesting to see what results you get, would be nice if that's it and a simple shield would solve the problem.

As an aside are you sure push rod length is correct ?

When I built my 393w I had a very noisy rocker issue, long story short I ended up using the "Straub" method to measure

push rods, ordered revised length which greatly reduced the noise.

It's been my experience that these roller set ups tend to be a little noisy even when properly adjusted.

High impedance circuits (100KΩ or higher) like sensors are sensitive to signal interference from radiated EMI. The fuel injectors are low impedance because it takes a fair amount of electrical energy to pulse that solenoid. Electrical interference radiated from an ignition coil doesn't pack that kind of energy to make the injector pulse or change the pulse width or characteristics.Found a problem.... I pulled the plugs and #4 is near fouled... #8 is slightly darker than the front 6. Only thing I can think of is the fact these injectors sit directly under the coil packs, I am going to create a shield on the injectors back there with tin foil. This will at least rule the coils out as interference, I am also swapping the coils and plug wires to rule out weak spark. If a new plug in that hole fouls again I will be forced to assume it's a bad/leaky injector.

The front 6 plugs look perfect, I may have to try something different... like using a plug slightly hotter in those two holes.

If nothing else the shield I made will keep any interference from affecting the sensors as the harness runs under the coils as well. We will see if the new coil packs and wires make a difference, the cheap store brand wires dont fit in the coil tower tightly and always seem loose.

I will ohm test the injectors and see if there is a discrepancy. I will put in new plugs and give it 50 miles to see if that cylinder loads up again.

I will ohm test the injectors and see if there is a discrepancy. I will put in new plugs and give it 50 miles to see if that cylinder loads up again.

Nope. They were new though... maybe I should just send them out, what kind of turnaround is there on this service?Have your injectors been flow tested?

Not sure, there’s a place by me that’s good (injector dynamics I think?) and there’s another dude on FB that everyone says does great work. I’ll probably send mine out too pretty soon.Nope. They were new though... maybe I should just send them out, what kind of turnaround is there on this service?

Steel1

Mustang Master

Years ago I used InjectorRX don't remember turn around time, I sent them out during the winter so return wasn't critical.

I've decided to move the injector and see if the problem follows it I'm going to put it on the driver side that's easy to get to even with the intake manifold installed. I lost an injector O ring and damaged another trying to put Them in without oiling them. Stupid me so once I pick some of those up in some new spark plugs I should be set to put this back together.

I have a extra bag of those just in case, but then you have to actually work on the car to need to use them

Injectors are back in and the intake has been reinstalled. I am going to move on to making the plug wires, once this is done i will test the engine for rocker noise again. going to run the engine with the blower belt off so i can clearly hear just the valve train.

Once this is done i will begin removal of the dash to install the new evap/heater core.... when i get in there i will inevitably find more hackerey from the PO and will spend more time than i want to fixing it. the goal is to have all the vents working as they should.

Once this is done i will begin removal of the dash to install the new evap/heater core.... when i get in there i will inevitably find more hackerey from the PO and will spend more time than i want to fixing it. the goal is to have all the vents working as they should.

- Jul 7, 2005

- 1,563

- 1,197

- 164

Looks like you are moving right along. I remember doing the heater core in mine...fun...fun

Timeline on the new pulley? Dyno session?

Timeline on the new pulley? Dyno session?

No idea when the new pulley will be here, i have not received the invoice yet.... may need to call them again, a company like that stays pretty busy. once i have everything working i will do a few dyno runs, no meth with the bypass open, then pulls with the bypass working and meth. at 10:1 i dont want to try 13 psi with no meth or intercooler........Looks like you are moving right along. I remember doing the heater core in mine...fun...fun

Timeline on the new pulley? Dyno session?

Similar threads

- Replies

- 93

- Views

- 27K

Good luck!

Good luck!