i have a vibration i just cant trace down. i have a 1970 with a 408 quick time bell stage 3 clutch tko 600 3.5 alum drive shaft cury rear with 3.83 gears. everything is new vibration was there with old drive shaft so not ujoints. its there under acceleration and coast seems to get worse when i push in the clutch ive even tried shuting the motor off and still clutch in nasty vibration. and help would be great

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vibration

- Thread starter Wi70

- Start date

-

Sponsors (?)

horse sence

15 Year Member

the car is stock height but would the tko 600 being longer then the c4 change that?Pinnion angle .

tos

Founding Member

So engine off and coasting you are getting a vibration? If not the pinion angle then how about driveshaft being too long and bottoming out in the tailshaft of the tranny?

tos

Founding Member

tos

Founding Member

Mustang Harry

Active Member

- Jun 13, 2017

- 48

- 47

- 28

Seems you have lots invested, but a dumb (at this point) are you sure the harmonic balancer and the flywheel are a matched pair ? Just a thought, if not, nothing else you do will cure the vib. I'm 80 and OLD SCHOOL, but have been restoring and building modified's since 1977 and have seen lots of simple mistakes that cause lots of stress. I have 15 mustangs,(most are now for sale) I'm a machinist by trade and have a monster 67 fastback, still in progress, and have had many problems here. Two (2) 351 C engines, solid frame, S/S 24 inch pipes, four 4 bbl's, 9" disc brake rear, body's welded, molded one piece and raises like a funnycar.

Attachments

tos

Founding Member

Seems you have lots invested, but a dumb (at this point) are you sure the harmonic balancer and the flywheel are a matched pair ? Just a thought, if not, nothing else you do will cure the vib. I'm 80 and OLD SCHOOL, but have been restoring and building modified's since 1977 and have seen lots of simple mistakes that cause lots of stress. I have 15 mustangs,(most are now for sale) I'm a machinist by trade and have a monster 67 fastback, still in progress, and have had many problems here. Two (2) 351 C engines, solid frame, S/S 24 inch pipes, four 4 bbl's, 9" disc brake rear, body's welded, molded one piece and raises like a funnycar.

Yes he said this happens with the engine shut down while costing (moving)

tos

Founding Member

Pinion angle is still a good possibility.

I'm going to throw out a couple vague possibilities

1. Bent axle or wheel?

2. loose wheel?

3. improperly setup ring and pinion?

maybe remove the driveshaft and jack it up and rotate the differential and watch and listen?

I'm going to throw out a couple vague possibilities

1. Bent axle or wheel?

2. loose wheel?

3. improperly setup ring and pinion?

maybe remove the driveshaft and jack it up and rotate the differential and watch and listen?

Real time recon

Mustang Master

I had new 4 tires mounted.Everything was smooooooth,then.A week later developed Vibration.Come to find out, wheel weight went Flying

it was there before the iersI had new 4 tires mounted.Everything was smooooooth,then.A week later developed Vibration.Come to find out, wheel weight went Flying

ok angle is positive 1% i took the tracton bars off and the big vibration is gone but it stil has a vibration under hard accleration. not sure what speed it is at becse i have to baby it to around 40 with out the traction bars or it will spin and hop. what would a good angle be and the bars are scott drake weld ons

BeastsNMonsters

Member

Weird question: is the axle housing straight? Is it perfectly perpendicular to the driveshaft? I think since removing the traction bars reduced the vibration, either they were incorrectly installed, or your axle tube is out of alignment.ok angle is positive 1% i took the tracton bars off and the big vibration is gone but it stil has a vibration under hard accleration. not sure what speed it is at becse i have to baby it to around 40 with out the traction bars or it will spin and hop. what would a good angle be and the bars are scott drake weld ons

Possible causes: bent axle tube, worn leaf spring bushings (rubber severely degraded/missing), bent leaf mounts, one spring backwards.

tos

Founding Member

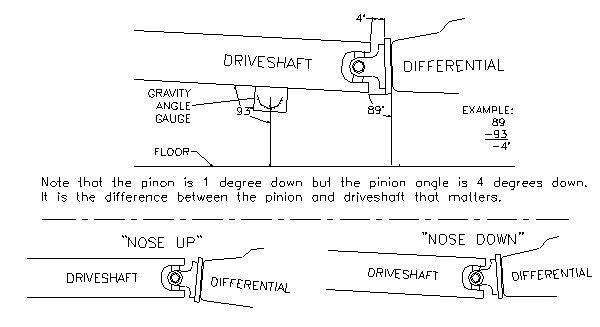

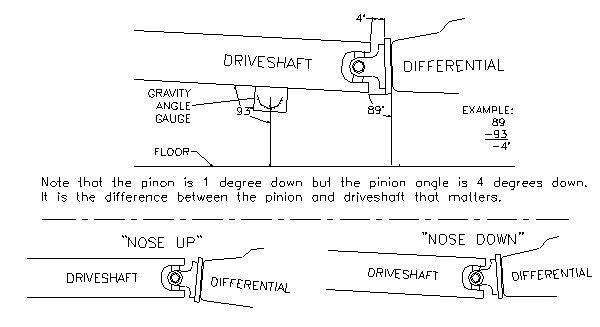

I believe you are still looking at pinion angle issues. There is no set angle for just the rearend if you have made mods. I think if everything were stock (tranny and suspension height) you could probly set it at a standard (common) angle but if your aftermarket tranny is longer then this changes required pinion angle. The best angle is calculated depending on engine and tranny angle in conjunction with pinion angle. It can get complicated to figure it exactly but To make it simple I think the idea is to have your pinion angle at the same degree of angle as your engine but opposite direction. In other wards if the engine and tranny are at 3 deg negative then the rear should be 3 deg positive.

But now the angle of the driveshaft figures in too. For instance if you jacked the cars suspension way up in the back like we did in the 60s and 70s then the driveshaft is at an exaggerated angle while the engine vs tranny are at the stock angles. I posted some pics that hopefully will explain better.

I think that since those traction bars have harder urethane bushings that they were merely transferring and exaggerating your vibration directly to the frame. They are not allowing the full force to be absorbed by the more forgiving leaf springs which is how they eliminate wheel hop by removing all that flexing of the springs. Your problem is still there but absorbed a little more.

Are you using any kind of lowering blocks?

I would look first for anything obvious like alignment of rear wheels compared to front.

make sure the spring perches are seated on the leafs completely (I'm sure you've already done all this though).

But now the angle of the driveshaft figures in too. For instance if you jacked the cars suspension way up in the back like we did in the 60s and 70s then the driveshaft is at an exaggerated angle while the engine vs tranny are at the stock angles. I posted some pics that hopefully will explain better.

I think that since those traction bars have harder urethane bushings that they were merely transferring and exaggerating your vibration directly to the frame. They are not allowing the full force to be absorbed by the more forgiving leaf springs which is how they eliminate wheel hop by removing all that flexing of the springs. Your problem is still there but absorbed a little more.

Are you using any kind of lowering blocks?

I would look first for anything obvious like alignment of rear wheels compared to front.

make sure the spring perches are seated on the leafs completely (I'm sure you've already done all this though).

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 6

- Views

- 1K

- Replies

- 48

- Views

- 5K